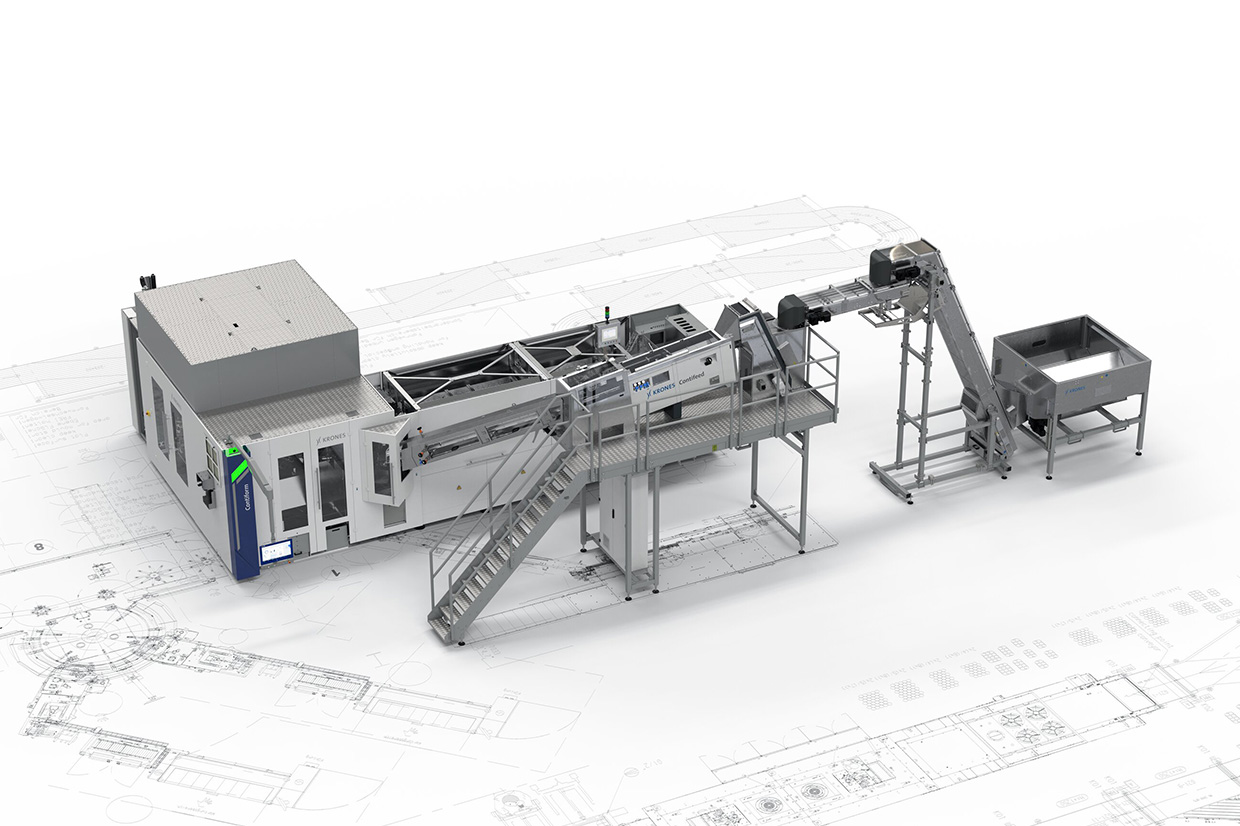

Eco-friendly design and operation

Environmentally sound and sustainable operation – That was one of the paramount goals for this latest evolution of the Contiform. When it comes to stretch blow-moulders, the most effective levers for achieving them are cutting energy consumption for preform heating and, of course, reducing compressed-air consumption in the blow-moulding process.

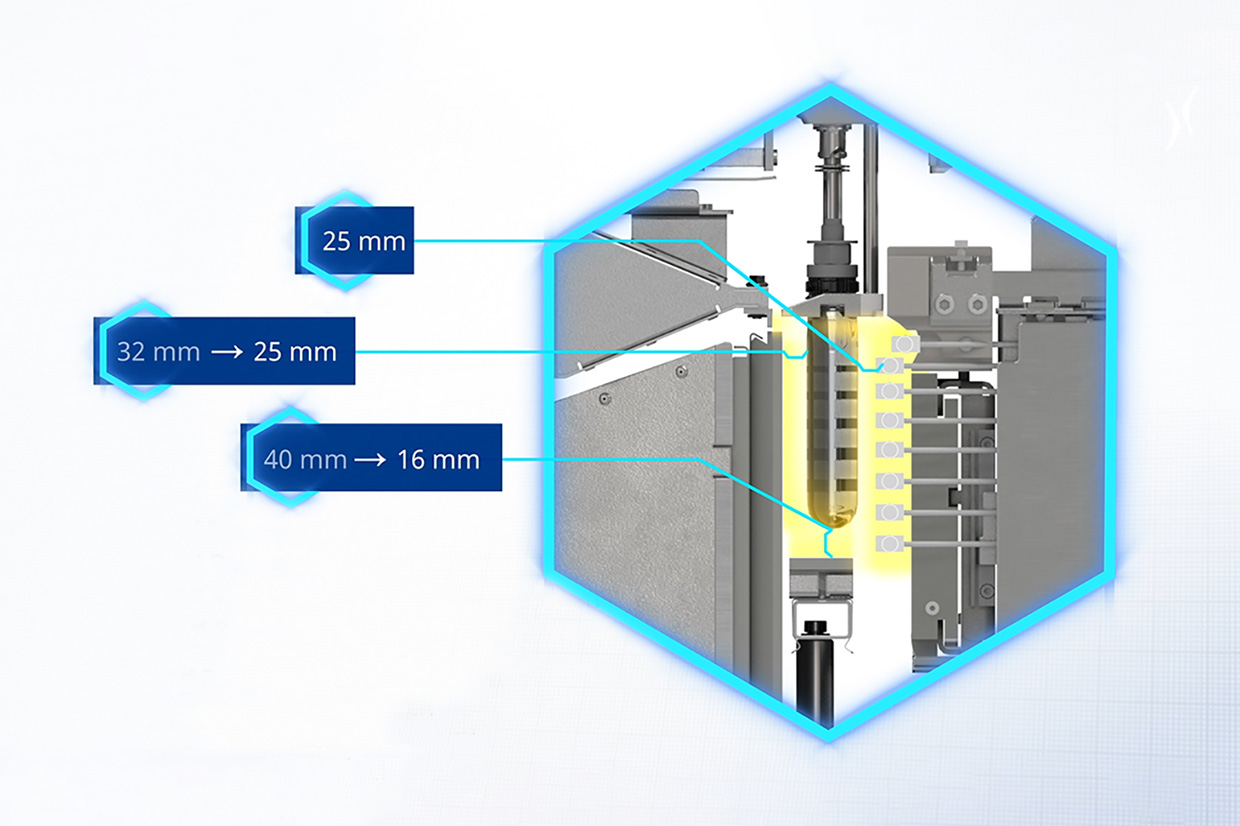

Thanks to shorter distances between the heaters, a more compact heating space and redesigned heaters featuring parabolic reflectors, energy consumption has been cut by another eleven per cent compared to the previous generation. The fourth generation also provides substantial savings on compressed air. The newly developed Air Wizard Triple air recycling system uses a three-stage recycling process, which makes it possible to reduce compressed-air consumption by as much as 20 per cent as compared to the technology customary on the market to date.