The turbo stretch blow moulder for the PET bottle production

Up to 100,000 containers per hour

Your efficiency sets new standards. In terms of high-pressure air and energy consumption, it once again undercuts everything that came before it: The fourth generation of the Contiform is here!

It uses the market-proven technology of its predecessor - but only asa basis. For be it flexibility, hygiene, user-friendliness or digitalisation: In the course of a complex development project, the blow moulder has been given a whole series of new features and optimisations.

The machine is also once again greatly improved as regards its output: The speed variant can break the 100,000 containers perhour barrier with ease –without forfeiting its sustainability.

At a glance

- Container and product range

- Container volumes of 0.1 to 2.0 litres

- Cylindrical, square and rectangular containers

- For still and carbonated products

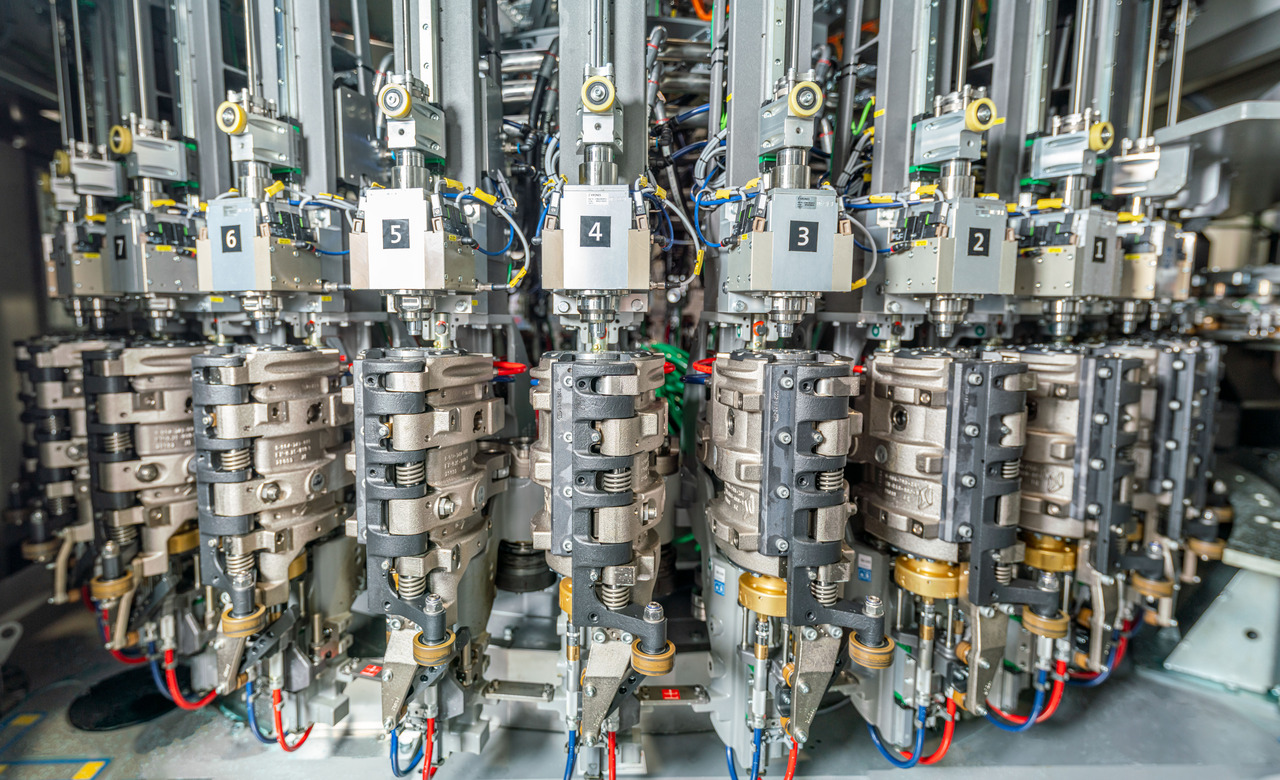

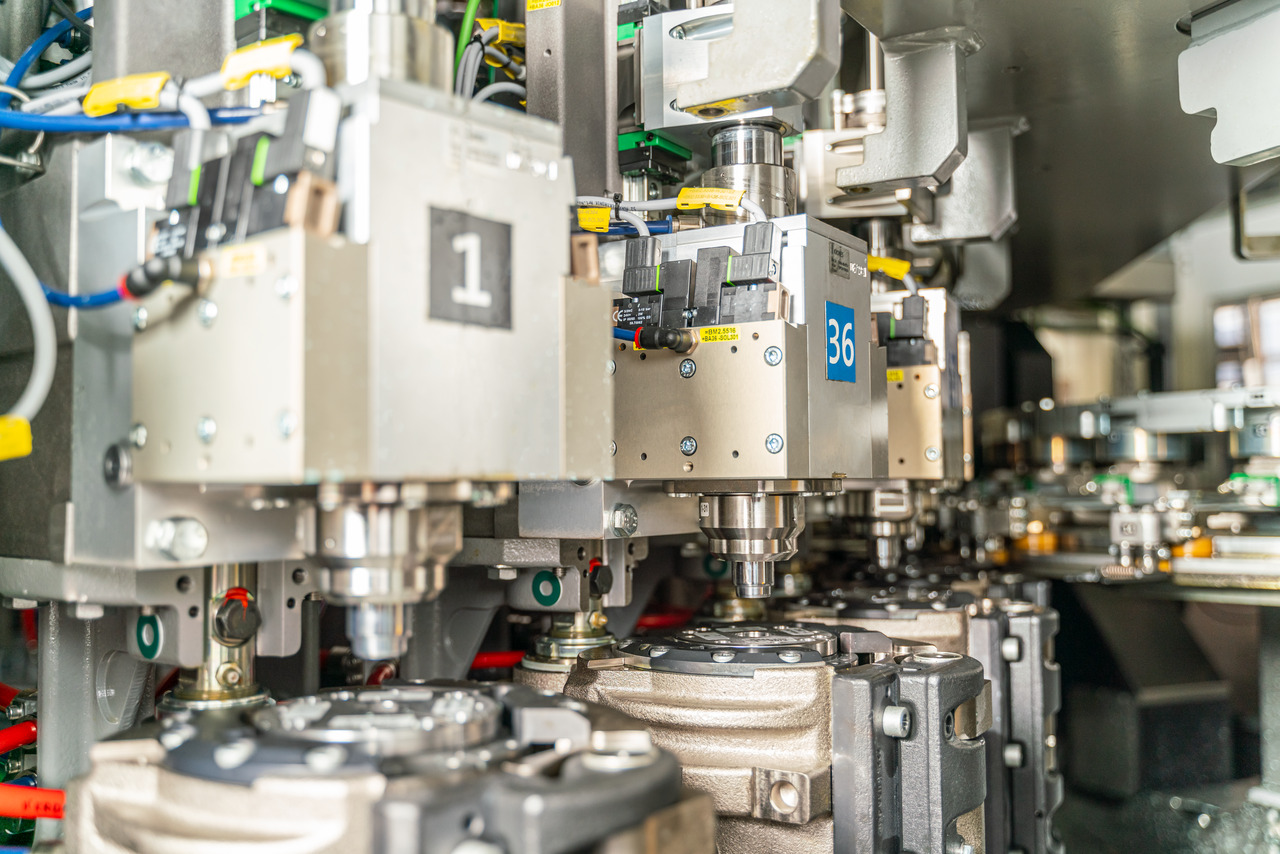

- Machine portfolio

- 8 to 36 blowing stations

- Output per hour

- Production of 8,000 to 100,000 containers per hour

The newest generation of Contiform

The design

The Contiform has a modular design and can be individually equipped for to meet all requirements.

*Optional

Basic machine

- Linear infrared heating module for processing preforms with a length of up to 160 mm and a support ledge diameter of up to 48,5 mm

- Blowing module with blowing stations for manufacturing containers of up to 2.0 litres

Optional modules

- Prejet preform interior cleaning system for pre-cleaning the incoming preforms

- PET-View inspection system for the integral quality control of preforms and containers

- MouldXpress Robot automatic mould changer for highly efficient change-over without manual intervention

- Self-learning Contiloop AI process control for fully automatic and intelligent parameter adjustment

Modules

Focussed on performance right from the beginning

At a glance

- Applicable with lightweight, standard and heavy preforms

- Three models –suitable for the respective blow moulder output

- Two variants of the feed rail:

- Gravity system for all common preform types

- Air-assisted –ideal for lightweight preforms and high-speed applications

Optional

- Automatic adjustment for quick change-over

- Hygienic design

- Soft-tilting preform tipper for a particularly gentle preform infeed

Benefits to you

- Automatic troubleshooting

- Quick and infinitely variable adjustment to every preform type

Efficient and flexible

Heating tunnel

- Very small oven chain (36.4 mm or 50 mm)

- Additional reduction of the heating room

- Adjustable base reflectors: adjustable to the respective preform length

- Maintenance-free system of ceramic reflectors

Heaters

- Parabolic reflector for the top infrared emitter

- Longer infrared emitters and smaller dead spaces between the heaters

Benefits to you

- Up to 15 percent smaller footprint thanks to reduced deadspaces

- Improved lightweighting potential through targeted heating of the preforms directly below the support ledge

- Up to 5 percent lower heating energy consumption due to shorter distances and parabolic emitter technology

Robust and precise

Transfer system

- Five-point heating mandrel in the linear oven

- Only four internal horizontal preform and container transfer points

- Actively controlled transfer grippers

Platform and drive technology

- Torsion-resistant platform construction with skip-and-run technology

- Five high-precision Monotec servo motors with real-time synchronisation

Benefits to you

- Precise transfer of preforms and bottles

- Perfectly suited for very light preforms

- No PET dust deposit

- No change of handling parts if the neck finish remains the same

- Significantly reduced scrap rate thanks to skip-and-run technology

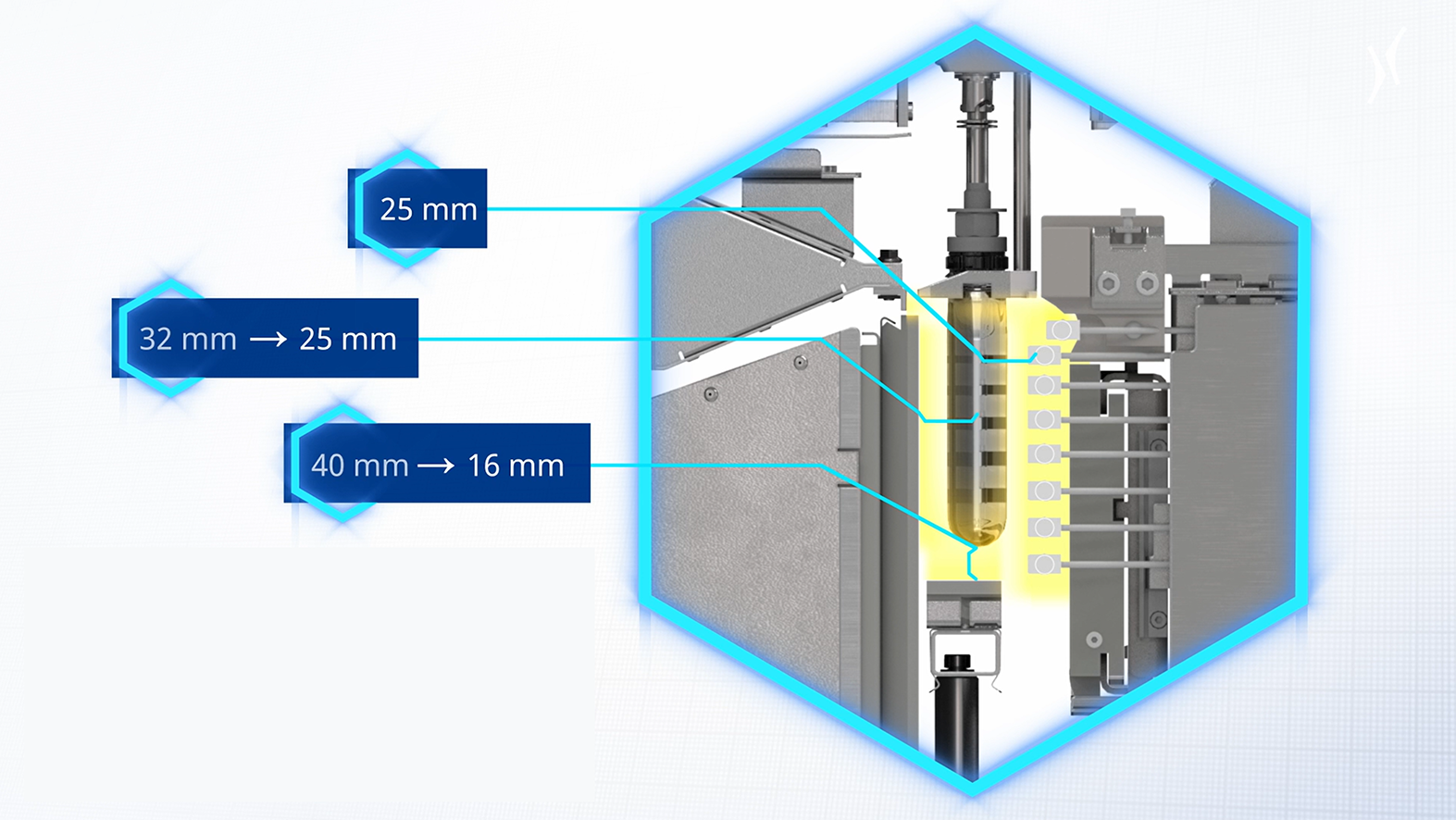

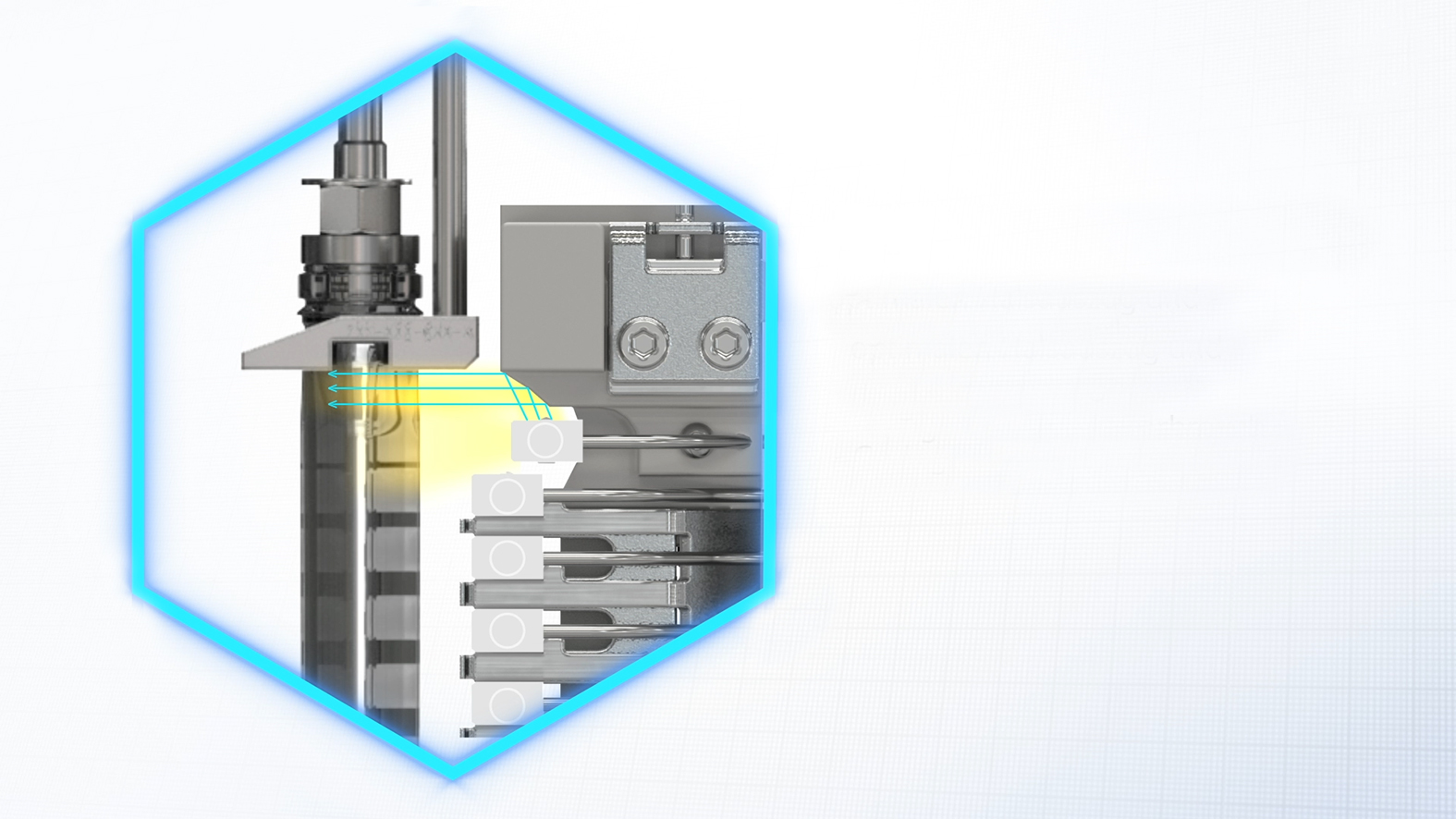

Intelligent while saving on compressed air

Blowing stations

- Electromagnetic stretching system without air consumption

- Extremely low dead space volume in the entire blowing station, among other things through the omission of the pressure compensation chamber in the mould carrier

Compressed-air recycling

- Once again a further developed compressed-air recycling system, the Air Wizard Triple

- With intermediate pressure stages for internal recovery of the compressed air

- Automatic self-optimisation of the blowing air recycling process

- Considerably lower valve switching time dispersion

Benefits to you

- Up to 30 percent less blowing air consumption in comparison to the valve technology used up to now

- Avoidance of potential incorrect settings

- Larger process windows thanks to increased accuracy of the blowing process

Bottle design and moulds

Creative and in line with the market

At a glance

- Four production centres worldwide with state-of-the-art manufacturing technology

- Container design experts at all four locations

- Design and production of mould types for all Contiform series

- Mould validation on our own technical centre systems

Benefits to you

- Customer-oriented consulting: Creative, functional, unique

- Individual designs with a view to customer requirements and feasibility in the beverage line

- Experience from more than 20,000 moulds per year

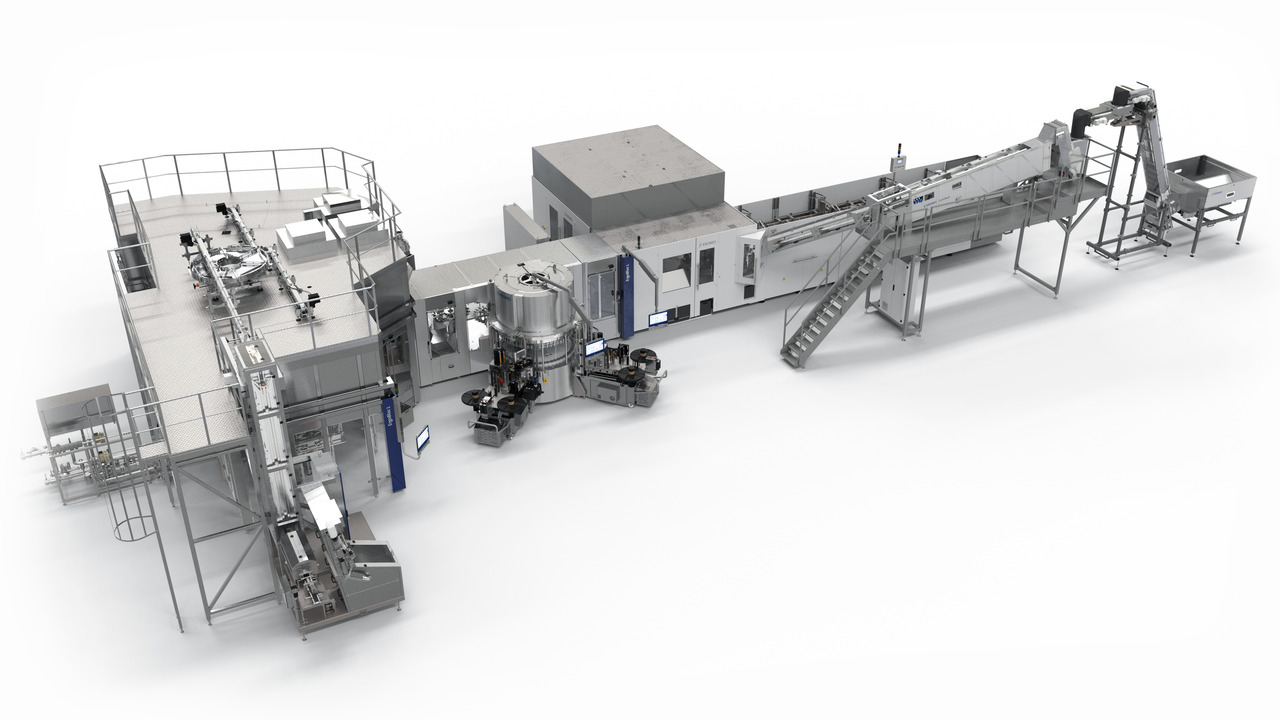

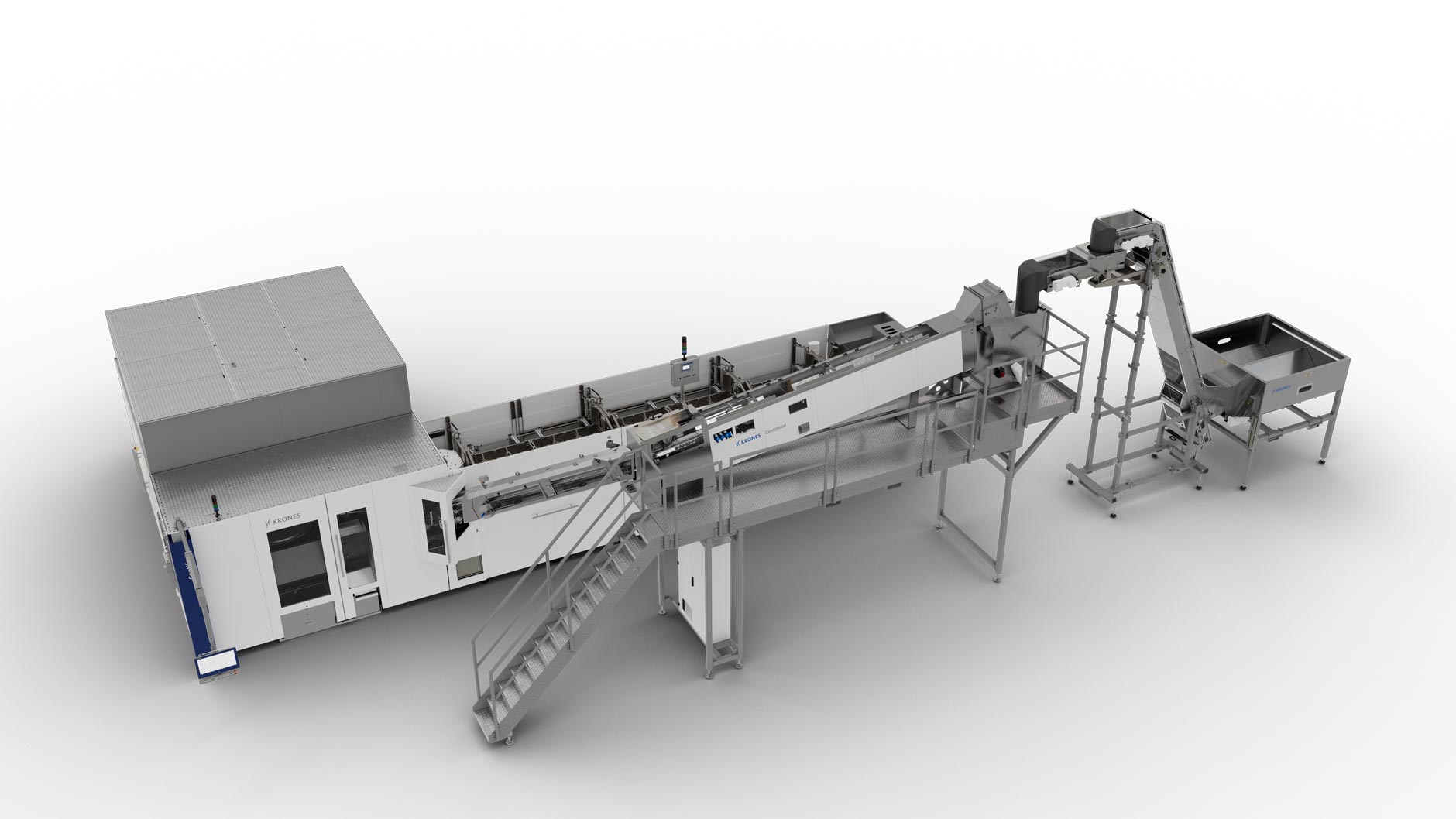

Better in combination: Contiform block solutions

A high output in a small space

Flexible block solutions

- Contiform Bloc: Blow moulder with filler or labeller

- ErgoBloc L: High-performance block consisting of blow moulder, labeller and filler

Compact block solutions for non-carbonated water filling

- Contiform Bloc BF-C: blow moulder and filler

- ErgoBloc LM: Blow moulder, labeller and filler

- More than 50 years of experience in block technology

- More than 2,000 Contiform block solutions sold worldwide

- More than 80 percent of all Contiform blow moulders are supplied in block configurations.

Benefits to you

Reduced heating energy consumption

The further optimised infrared heating technology made it possible to reduce the energy consumption for heating the preforms by up to an additional 5 percent.

Production efficiency

With its sturdy design and new functions, such as skip-and-run, the new Contiform continues to operate with the utmost reliability and with even less interference than before.

High-pressure air efficiency

The Air Wizard Triple can achieve a high-pressure air saving of up to 30 percent compared to the previous generation.

Ergonomic design and user-friendliness

The servo drives in conjunction with the improved rotary joint continue to keep the noise level stress-free, even at the highest output rates. The new operating interface with large touch-screen allows for even more efficient working with the machine.

Why the new Contiform is enviro-classified

Energy efficiency

- Further optimised heating room and heaters for the lowest possible heating energy requirement

Compressed-air efficiency

- Further developed compressed-air recycling for the highest possible internal and external reuse of the blowing air

Environmental compatibility

- Further minimised lubricant consumption − Use of components made of recycled material