Krones Process Technology is focused on the production of oat drinks

Milk alternatives made from soy, almond or oats have long since established themselves on our supermarket shelves. The reasons for their major popularity are varied and range from health aspects to an intrinsic motivation to achieve more sustainable nutrition.

Also the world of milk alternatives itself is rich in variety: Grain types such as oat or rice suit also for production as nuts (for example almond or coconut) or legumes such as soy or peas. Each group of raw materials has certain properties and details which need to be taken into account during production.

Krones has focused particularly on the production of oat drinks and offers three different process variants in this context. We would like to present these in a little more detail below. You can read even more about the technical details and the differences between the various options in the brochure linked.

Variant 1: production from finished oat base

Raw-material base: ready-to-use oat base

Overview of the most important process steps:

Suitable for: beverage manufacturers who already own a syrup room and would initially like to test the production of grain-based drinks for themselves and their brand

- Existing equipment can be used (minor extensions may be required)

- Swift market entry possible

- Preservation of flexibility as it is possible to react relatively quickly to changing market requirements

- But: relatively high production costs as the basic material is purchased ready-to-use

Variant 2: production from oatmeal

Raw-material base: ready-to-use oatmeal

Overview of the most important process steps:

Suitable for: producers who wish to produce medium-sized quantities of oat drink quickly and reliably

- Swift market entry possible

- Allows individual recipes as the product characteristics can be directly controlled in the hydrolysis process. Recipe can be developed independently from the raw material supplier

- More cost efficient than variant 1 in the long term as oatmeal can be purchased cheaper

Variant 3: production from whole oat grains or flakes

Raw-material base: whole oat grains or flakes

Overview of the most important process steps:

Suitable for: producers who attach great value to high product quality and a sustainable overall concept (low energy requirement for greater production quantities)

- Allows individual recipes as the product characteristics can be directly controlled in the hydrolysis process. Recipe can be developed independently from the raw material supplier

- Use of brewery technology makes it possible to control and adapt the hydrolysis process even more effectively

- Energy-efficient variant: focus on a holistic energy concept

- In the long term, the least expensive of the three variants as regards production costs

In Detail: Oat drink production using whole oat grains or flakes

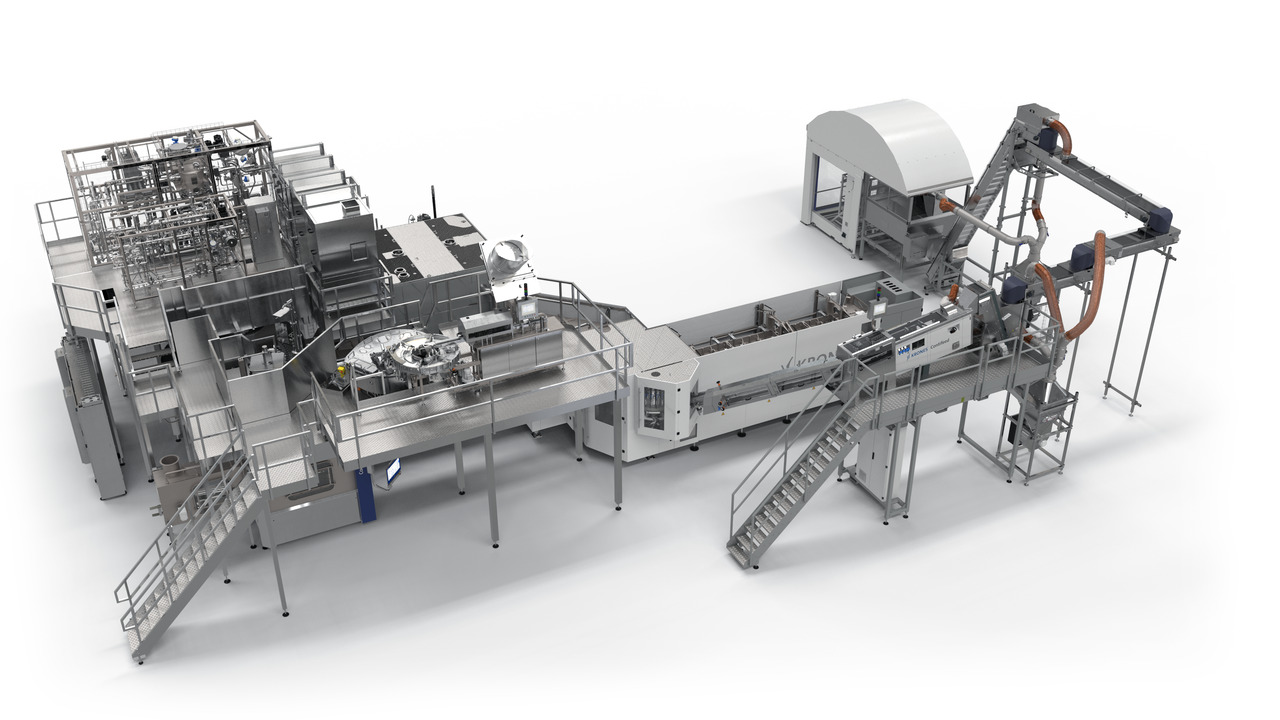

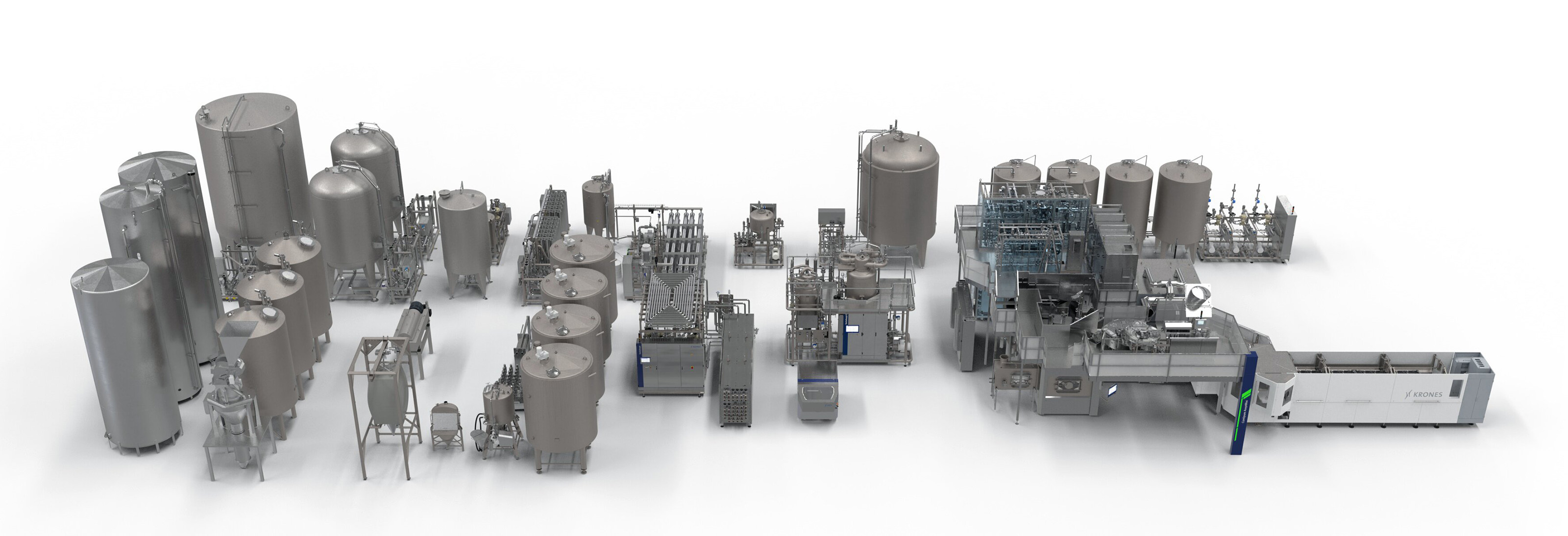

Sample representation of an oat drink line

7. Aseptic filling

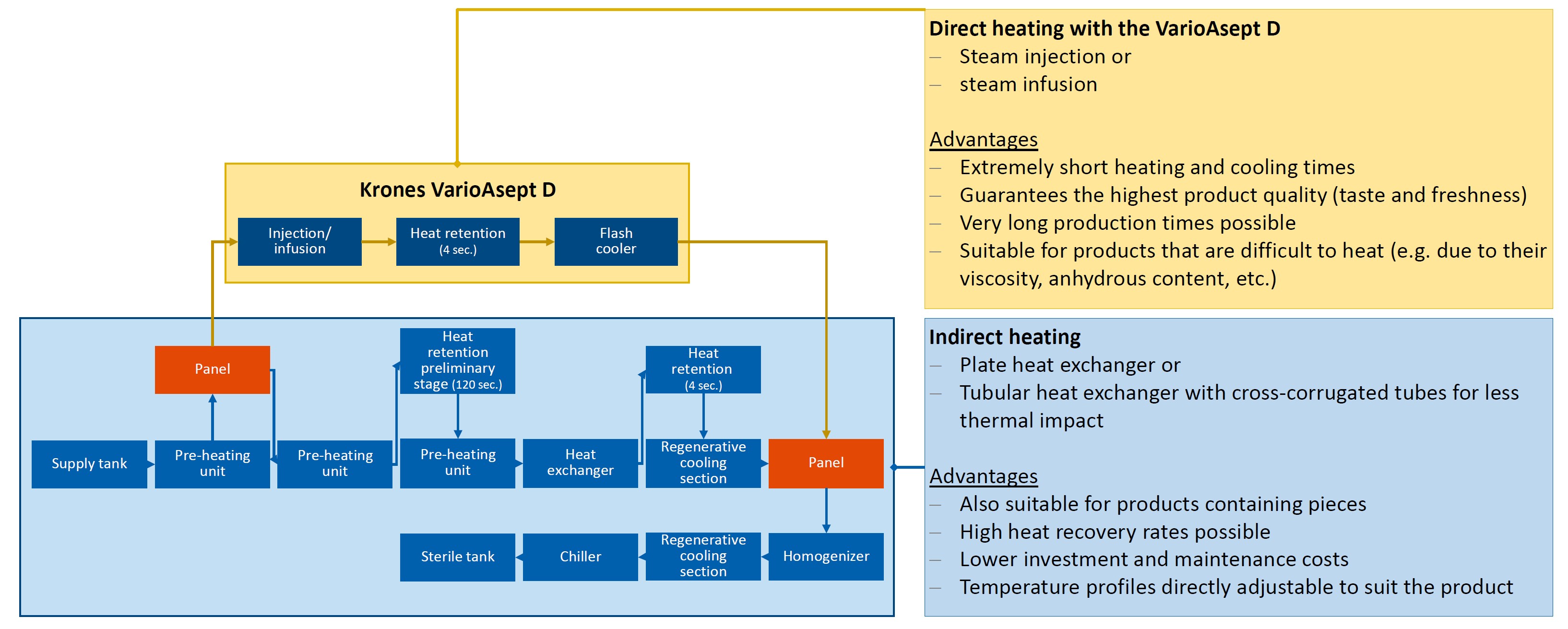

6. Flexible heating options

5. Product treatment and homogenization

4. Separation of solids and liquids, blending of additives

3. Hydrolysis

2. Mixing of meal and water

1. Water treatment

1. Krones Hydronomic water treatment system

In addition to select, high-quality raw materials, the second major ingredient that is important for plant-based milk alternatives is water. And here you can benefit from our turnkey abilities – as Krones is the only supplier in the world who can also include knowledge about ideally treated water, as well as the corresponding line technology. The Hydronomic is designed exactly with a view to plant-based milk alternatives and makes it possible to achieve a standard water quality with a low TDS content and without taste impairments.

2. Intensive mixing of oatmeal and water

Before adding enzymes (hydrolysis), an optimised mixing of oatmeal and water guarantees a homogeneous suspension. This procedure is performed in a pre-masher. Its proven technology permits dust and lump-free mixing up to a ratio of 1:2.

Method of operation: expansion as the driving force

- The meal is fed from above and the water then added horizontally in a pocket.

- Swirl vanes at the nozzle outlet of the pocket increase the turbulence in the mixing zone.

- The reduced diameter after the pocket increases the flowing speed and thus causes the media to expand.

- This guarantees that the solids are distributed optimally in the liquid medium.

- These measures force an intimate contact between the finest particles and the water.

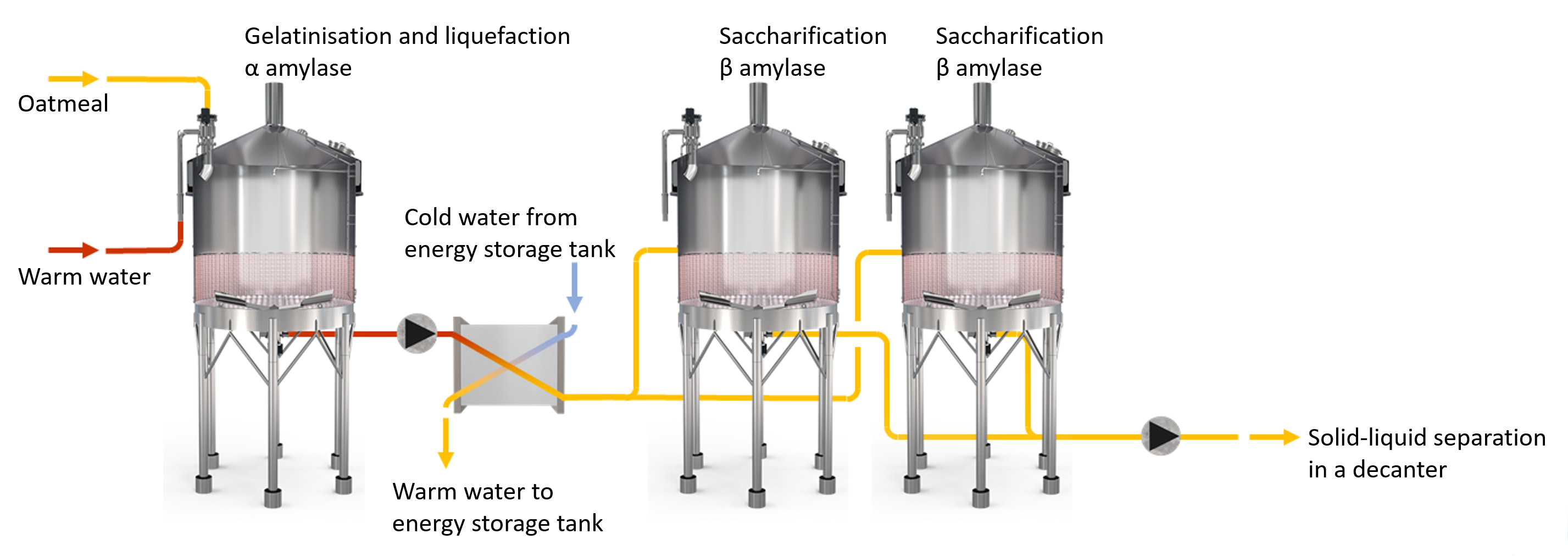

3. Hydrolysis: key process for the final product quality and yield

- Particulate starch is made up of alternating hard and soft layers.

- The structure and thickness of the individual layers depends on the growth conditions and influences the gelatinisation temperature of the starch.

- The yield, sweetness and mouthfeel of the finished product depend on the:

- gelatinisation temperature of the raw material

- Liquefaction of the starch through the effect of α-amylases at temperatures between 80 and 85 °C

- Saccharification with β amylases and glucosidases, that separate maltose from the end of the dextrine chain and have an optimal effect at approx. 60 to 65 °C

- The selection of the suitable enzyme (depending on the supplier) is crucial for the balance of the end product as regards sweetness, mouthfeel and yield.

- Preliminary trials are required to define the required end product.

Line concept for continuous hydrolysis - Sequence and duration of a sample process

- Filling and heating: 30 min.

- Gelatinisation and liquefaction: 30 min.

- Cooling to saccharification temperature: 25 min.

- Saccharification 30 min.

- Separation of solids: 85 min.

Optimal hydrolysis results: use of the technology in Steinecker mash vessels

4. Separation of solids and liquids and blending of additives

Separation of solids and liquids

After hydrolysis, the oat-water mixture first goes into a decanter that has to be additionally installed, in which the solids are separated from the liquids.

Blending

In the following process, the oat base is blended with various additives such as oil, salt, flavourings, stabilisers and possibly sugar, depending on the recipe, to form the finished beverage. The configuration can be individually adjusted to suit your requirements.

5. Product treatment

Krones VarioAsept M UHT system

- Specifically designed for use in the milk industry and thus in an ideal position to cater to the requirements of plant-based milk alternatives: At the end, reliably inactivates the enzymes needed for hydrolysis

- Output range: Between 3,500 and 60,000 litres per hour

- Proven design which

- meets the highest hygiene requirements

- Is extremely gentle on the product

- In-house laboratory for product analysis

- Perfectly matched with the Krones aseptic fillers

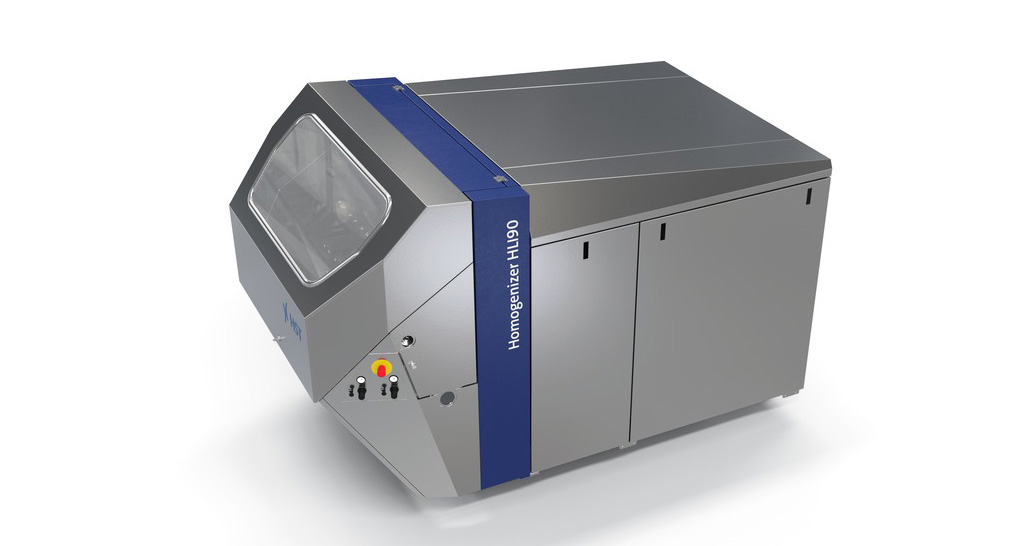

Homogenization is an important process step in the manufacture of plant-based milk alternatives. The system is located in the sterile area, meaning that aseptic homogenization is therefore performed. This way, the agglomerates formed during heating (regardless of whether directly or indirectly) can be removed again, which ensures a high product quality.

7. Aseptic filling systems

- 10-Year sterility guarantee available

- Automatic adjustment of the handling parts at speeds of up to 36,000 containers per hour

Especially for slightly acidic and pH-neutral products: Contipure AseptBloc

- FDA and 3A certificate available for the entire aseptic block arrangement

- All of the components in the clean room housing block can be completely sterilised: The sterile preform or container never leaves the sterile zone until it reaches the capper

- Up to 168 hours of continuous production in one go

- Output: up to 72,000 containers per hour