Water preparation for your product with character

The purity law for your water

Carbonated or non-carbonated, hot or chilled – regardless of how versatile our taste is for water, the demands for the basic elements of your product are just as versatile. With the Hydronomic water treatment systems, Krones provides an individual programme for careful treatment of your untreated water. Regardless if handling brewing or process water or raw material for soft drinks, juice or tea: With the Krones process technology, you will give your water exactly the character which will meet the requirements of your product and customers.

At a glance

- It operates with a water treatment process which is tailored exactly to your requirements

- It prepares between 5 and 120 m³ of water per hour – optionally with a variable production quantity

- Minimised waste water thanks to its sophisticated technology

- Best possible access for operators and service personnel

- Minimised cleaning chemicals due to the stainless steel construction which can be sanitised completely with hot water

- It can be expanded thanks to modular design

- Microbiological stabilisation before filling: ozonisation with the Krones Ozonomic

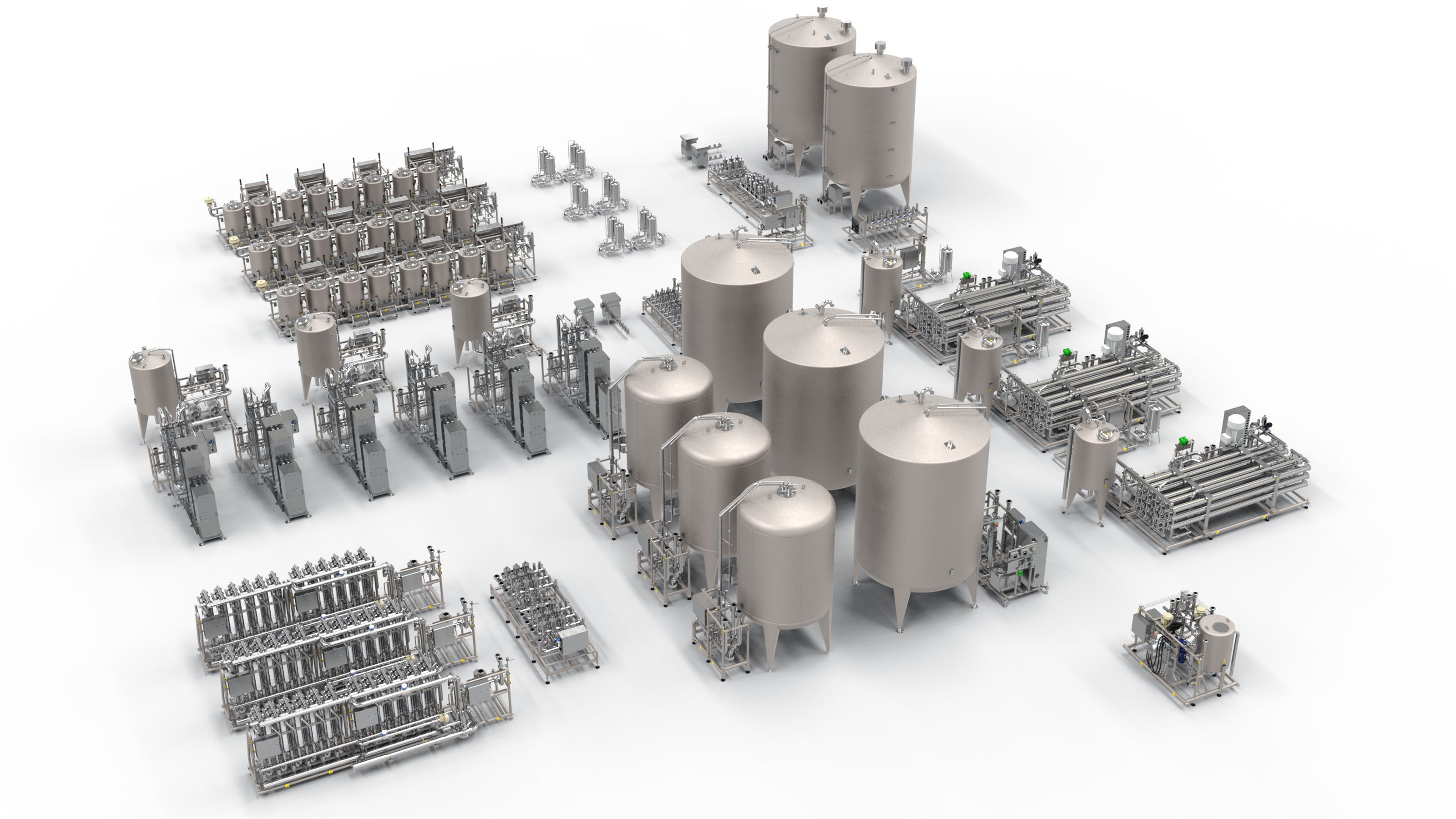

Our solutions for your water treatment

We will adapt the equipment of your individual treatment steps individually to your economic and technological requirements. With our modular component system, we will always find the correct solution – from the high-end all the way to a cost-attractive basic version.

MDS: Mineral dosing station

Hydronomic MDS

Thanks to the use of a mineral dosing station – in brief MDS module – you can remineralise your water exactly in line with your own formulas – for the highest possible flexibility and individualisation of your product.

EDI: electro-deionisation

EDI module

Electro-deionisation (EDI) allows you to produce ultra clean, deionised water which then merely requires the addition of the desired minerals. The use of this kind of additional EDI module is particularly recommended in cases where the untreated water quality fluctuates. This is particularly important in the manufacture of still table water where there must be no deviation in the mineral composition of the product.

RO: reverse osmosis

Hydronomic RO

Variable output regulation and automatic yield control ensure the highest possible flexibility and minimise scaling on the membranes. The membranes can also be flushed with permeate to minimise scaling and biofouling.

UF: ultrafiltration

Hydronomic UF

- The individual control of the filter modules in the Hydronomic UF guarantees uninterrupted production. Only ultrafiltrate is used during backflushing.

- Filtration performance: up to 150 m³/h

- Rinsing water consumption: max. 36 m³/h

- Yield: Up to 99.9 %

MF: media filtration

Hydronomic MF/GAC

- Filtration performance: up to 120 m³/h

- Yield: up to 99.5 %

Hydronomic MF/GAC (Media Filtration)

The module filters and adsorbs any unwanted and undissolved water content (suspended solids and odorants, organics, chlorine, iron, manganese, etc.) with different filter media (e.g. silica sand, manganese oxide, basalt and activated carbon).

Benefits to you

High hygienic standard

The filtration line is fully designed in stainless steel. This way, the entire line can be fully satinised with hot water.

Perfect filtration performance

The so-called fill of the filter media is selected targeted and individually adjusted to the respective application. This leads to optimal filtration results.

Gentle on the resources and the filter media

Filter media that ideally harmonise with each other, prolong the filtration cycles and minimise the necessary frequency of back-flushing. This saves water and increases the life cycles of most filter media.

Flexible line configuration

The modular line construction enables an easy expansion of the Hydronomic.

Hydronomic UF (Ultra Filtration)

The Hydronomic UF uses the most up-to-date membrane technology with hollow fibres (pore size of 0.02 µm) for the ultrafiltration of water in in/out operation. Typically, ultrafiltration is also used to extend the production time of an (optional) downstream reverse osmosis system by additionally filtering the water.

Benefits to you

Energy-efficient

In order to reduce the energy consumption, hollow fibres are used for filtration. They require less pressure and offer a larger filter surface.

Effective cleaning

The In/out concept offers optimum conditions for the effective and safe cleaning of the hollow fibre membranes. The stainless steel option allows for sanitising the equipment with hot water and without the need of any cleaning agents.

Non-interrupted operation – also during back washing

Thanks to the bypass structure of the filtration elements, the individual modules can be cleaned during the operation by backwashing with the ultra filtrate. This way, the usually used decoupling tank and its belonging backflushing pump are not required.

High-quality line concept

The Hydronomic UF is equipped with high-quality components, both in its stainless steel design and in its basic version. This way, the line is designed especially for a long service life.

Cleaning with filtrated media

During the CIP process, the used chemicals are dosed prior to the ultra filtration into the untreated water flow and are therefore filtered before being used.

Hydronomic RO (Reverse Osmosis)

The Hydronomic RO module serves to desalinate water down to a usual residual content of less than three percent. The generated water is then especially treated/remineralised for the respective application.

Benefits to you

Economic structure of the individual banks

If the conductance in the permeate is changed, the reverse osmosis elements can be tested inline and checked for malfunctions. Faulty elements can be replaced targeted and cost-saving.

Economic in the use of energy

Depending on the pre-pressure of the untreated water, the permeate performance is regulated. This provides a low energy consumption and a constant recovery rate.

Long-term guarantee

The investment in a stainless steel version which can be sanitised with hot water pays off: The omission of chemical cleaning agents increases the service life of the membranes. The guarantee is prolonged optionally by up to five years.

Modular structure with long service life

A long service life is achieved through the deliberate choice in favour of a modular system design and a high manufacturing quality. Thanks to their large overall size, there is only little stress on the membranes which therefore achieve long service lives.

Suitable rinsing steps with permeate

In order to prevent scaling, the line contents will be rinsed with permeate when needed.

Step-by-step CIP sequences

At the CIP process, the respective container can be filled with permeate and chemicals removed from it. The banks of the system are thus cleaned one after the other, or individually.

Benefits of the enviro-classified Hydronomic

Energy efficiency

- Use of energy-efficient motors and optimally designed pumps and heat exchangers

Media efficiency

- Reduced waste water quantity via automatically controlled yield

- Loss of water is prevented thanks to the recovery of coolant

Environmental compatibility

- Economical use of environmentally sound cleaning media due to intelligent control queries

- No use of chlorine and polluting disinfectants

This product is enviro classified

Top technology for ecologically efficient production

The Krones sustainability programme enviro: top technology for ecologically efficient production.