Close the Loop - Krones Recycling Technology Center

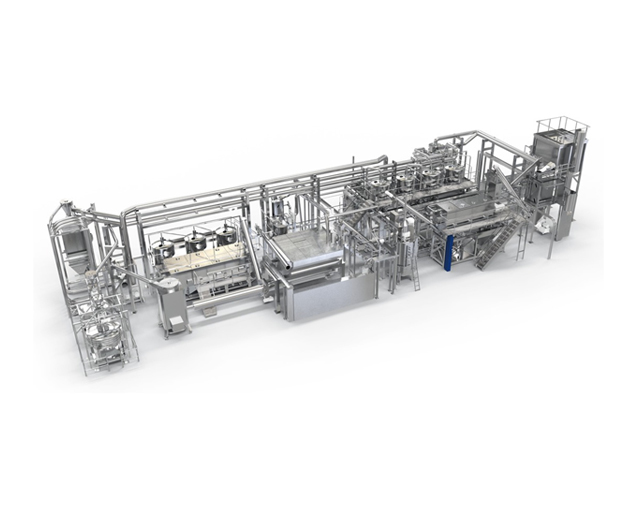

Our Recycling Technology Centre has been performing washing and SSP tests since 2004. The system, which we developed ourselves, handles both 2D and 3D fractions of the widest range of plastics, such as PET, PE, PP or PS. Its high flexibility makes it possible to perform both cold and hot washing tests in continuous operation mode, as well as SSP tests in batch mode.

Together with our customers, we develop solutions that are precisely tailored to suit individual applications. The core element of our philosophy is intensive research and development work – also and primarily in collaboration with our partners and suppliers.

We plan, implement and document individual recycling tests, from the bale right through to the new packaging.

Regardless of which plastic you want to recycle, in our Recycling Technology Centre we carry out tests from the bale right through to the new packaging. When doing so, we observe the entire recycling process:

- Pre-sorting

- Hot and cold washing

- Flake sorting

- Decontamination

- Pelletising

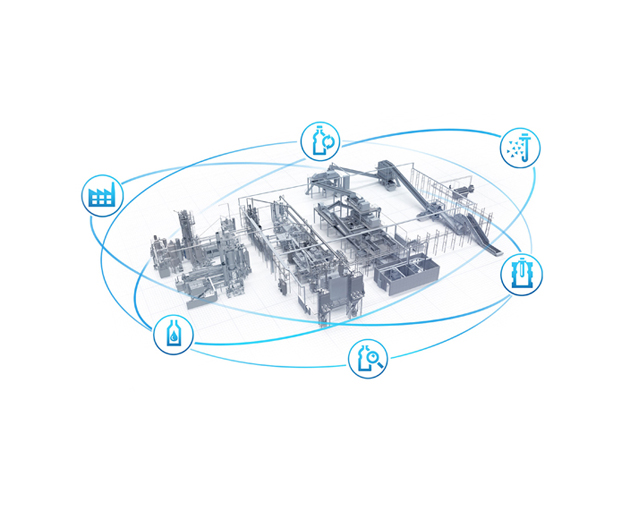

As a part of the Krones family, we are embedded in a network that extends across the entire plastics loop. This comprises, among other things:

- Know-how and services surrounding the design of packaging, in particular in the realms of lightweighting and design for/from recycling

- Know-how and technology for the further processing of recyclates, such as for example: Injection moulding tools, blow moulders, inspection systems, and bottling and packaging lines

- Collaboration with external partners from the field of research, the packaging industry, and sorting and recycling technology

As a part of the Krones family, we are embedded in a network that extends across the entire plastics loop. This comprises, among other things:

- Know-how and services surrounding the design of packaging, in particular in the realms of lightweighting and design for/from recycling

- Know-how and technology for the further processing of recyclates, such as for example: Injection moulding tools, blow moulders, inspection systems, and bottling and packaging lines

- Collaboration with external partners from the field of research, the packaging industry, and sorting and recycling technology

- In our test system, your material undergoes wet-grinding and volumetric dosing.

- The product is then conveyed through a hot or cold washing procedure comprising a variety of washing stages such as pre-washing, intensive washing and post washing.

- Impurities are removed from the production flow using multiple separation stages such as density separation, sifting and metal separation.

- A multi-stage drying sequence to reduce the amount of residual moisture completes the process.

- In our test system, your material undergoes wet-grinding and volumetric dosing.

- The product is then conveyed through a hot or cold washing procedure comprising a variety of washing stages such as pre-washing, intensive washing and post washing.

- Impurities are removed from the production flow using multiple separation stages such as density separation, sifting and metal separation.

- A multi-stage drying sequence to reduce the amount of residual moisture completes the process.

Our Recycling Technology Centre has a test system that simulates all of the process steps of the MetaPure S industrial SSP system in a representative and individual manner:

- In batch mode, both flakes and pellets can be processed in quantities of up to 7.5 kilograms daily.

- Tests to determine the behaviour of a range of materials can be evaluated, including: IV structure, reduction of contaminations and odours.

Our Recycling Technology Centre has a test system that simulates all of the process steps of the MetaPure S industrial SSP system in a representative and individual manner:

- In batch mode, both flakes and pellets can be processed in quantities of up to 7.5 kilograms daily.

- Tests to determine the behaviour of a range of materials can be evaluated, including: IV structure, reduction of contaminations and odours.

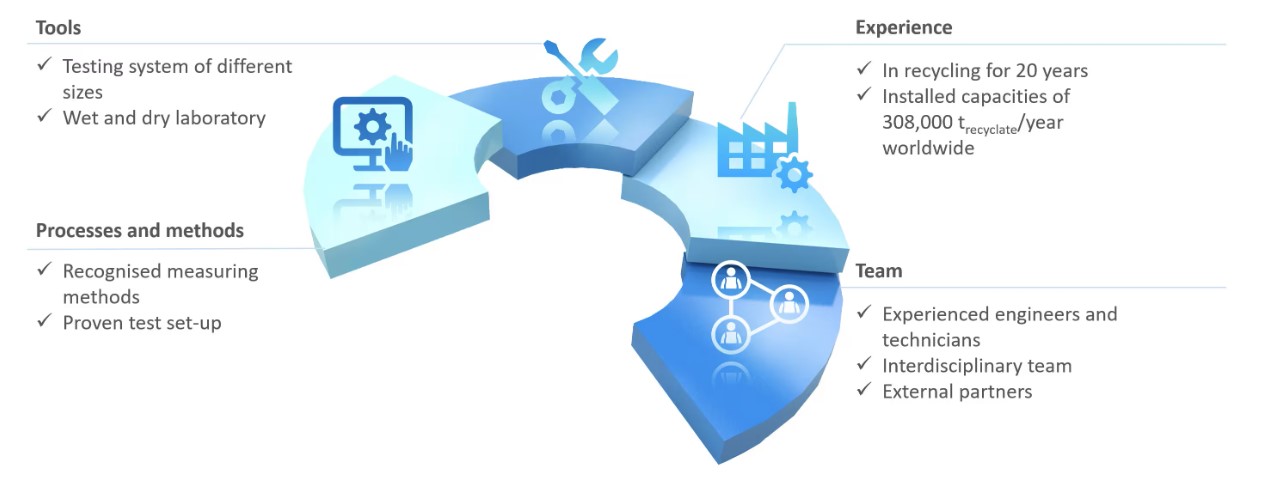

What makes us special

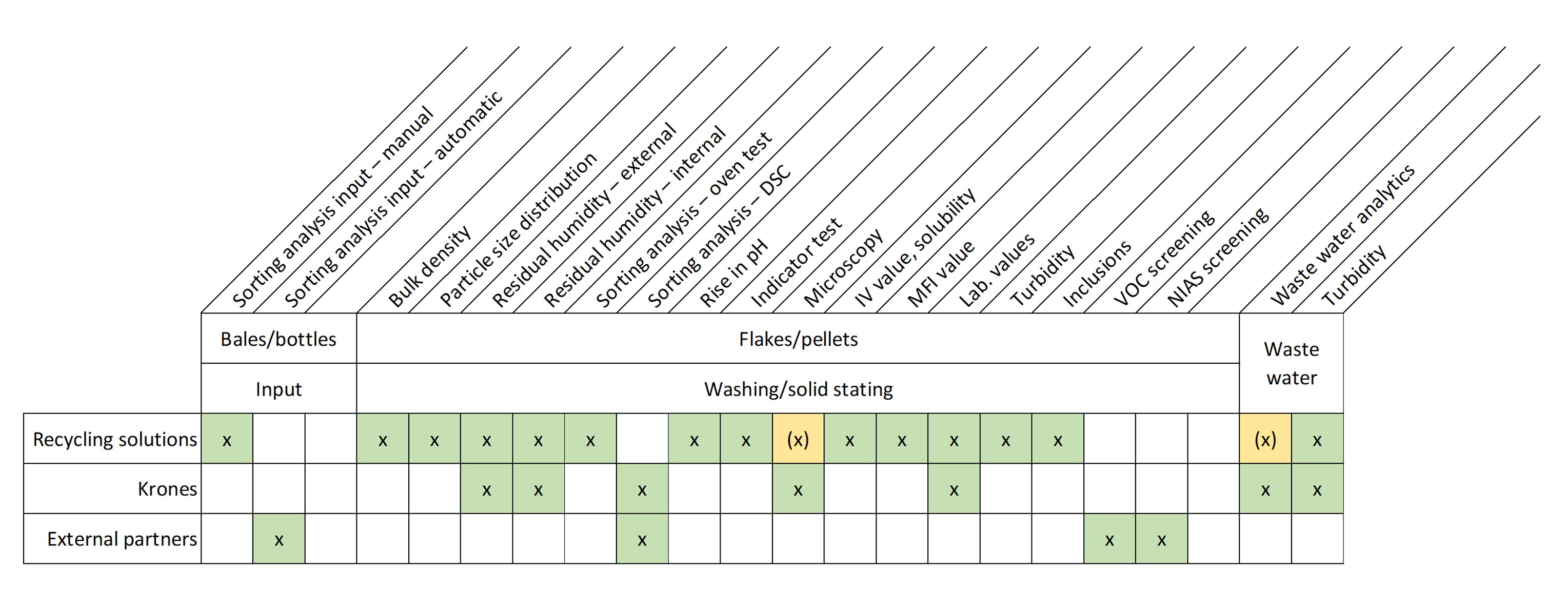

The test options we offer

Benefits to you

Tests as required

Regardless of whether you wish to examine bottles or other hollow objects, label films or other materials: in the Krones Recycling Technology Centre we perform individual washing tests with your desired material.

Professional and holistic

Would you like to gain substantiated information about the entire recycling process? No problem: we cover the entire loop from the bale through to the new packaging if needed. The tests are performed and supervised professionally by our in-house team of experts.

Valuable data and findings

On completion of the tests, you are supplied with a comprehensive test report with all of the calculated data. Our experts also discuss the most significant results and findings with you in a personal meeting. This means you have all relevant data and facts on hand to operate your processes and systems as efficiently as possible.

Easy online booking

Are you interested in having a test performed for you in our Recycling Technology Centre? In Krones.shop you can request an individual quotation including your preferred test date, both quickly and without obligation.