Experts when it comes to dairy products

In the Krones Group, particular focus is on milk – the white gold. We accompany your product from the point of generation, through all the components and all the way to filling with lines that are specifically designed for the dairy industry.

You can also entrust us your project execution and the after-sales service: Because our subsidiary Milkron employs real milk specialists who know the industry - and thus of course your requirements and wishes - just like the back of their hands.

At a glance

- Project processing, service and development of Milkron after-sales business

- Homogenisers by HST

- Evoguard pumps and valves

- Krones lines for processing and filling dairy products

- Consulting and development with regard to filling milk in PET bottles

From line planning to the finished product

Everything from a single source

No matter on which door you knock at the Krones Group: There will be competent support for your requirements and wishes everywhere. Our portfolio ranges from single lines and components all the way to the processing of complete line projects for the dairy industry:

The holistic expertise of Krones process technology

Comprehensive support from Milkron

Milkron has been the group’s dairy specialist since 2016, developing customized dairy solutions worldwide. Because the new company was staffed with industry veterans with decades of experience, Milkron was able to get off to a running start. Milkron also offers consulting services. The dairy experts support customers in developing feasibility studies and calls for tender, defining process technology requirements, and developing new products. Once a project is underway, Milkron assumes complete responsibility for the new dairy or individual systems. That includes coordinating and communicating with all suppliers involved. On-site installation and start-up are the responsibility of the respective site manager. Together with his team of experienced process and automation engineers, he ensures that every aspect of the project runs as it should so that the finished project can be handed over to customer on time and to the customer’s complete satisfaction.

Process technology from Krones

When choosing the right technology, Milkron has access to the Krones Group’s entire portfolio of machines and systems. As one of the leading one-stop shops for the beverage and liquid food industry, the Krones Group also has a wide range of solutions available for milk processing operations.

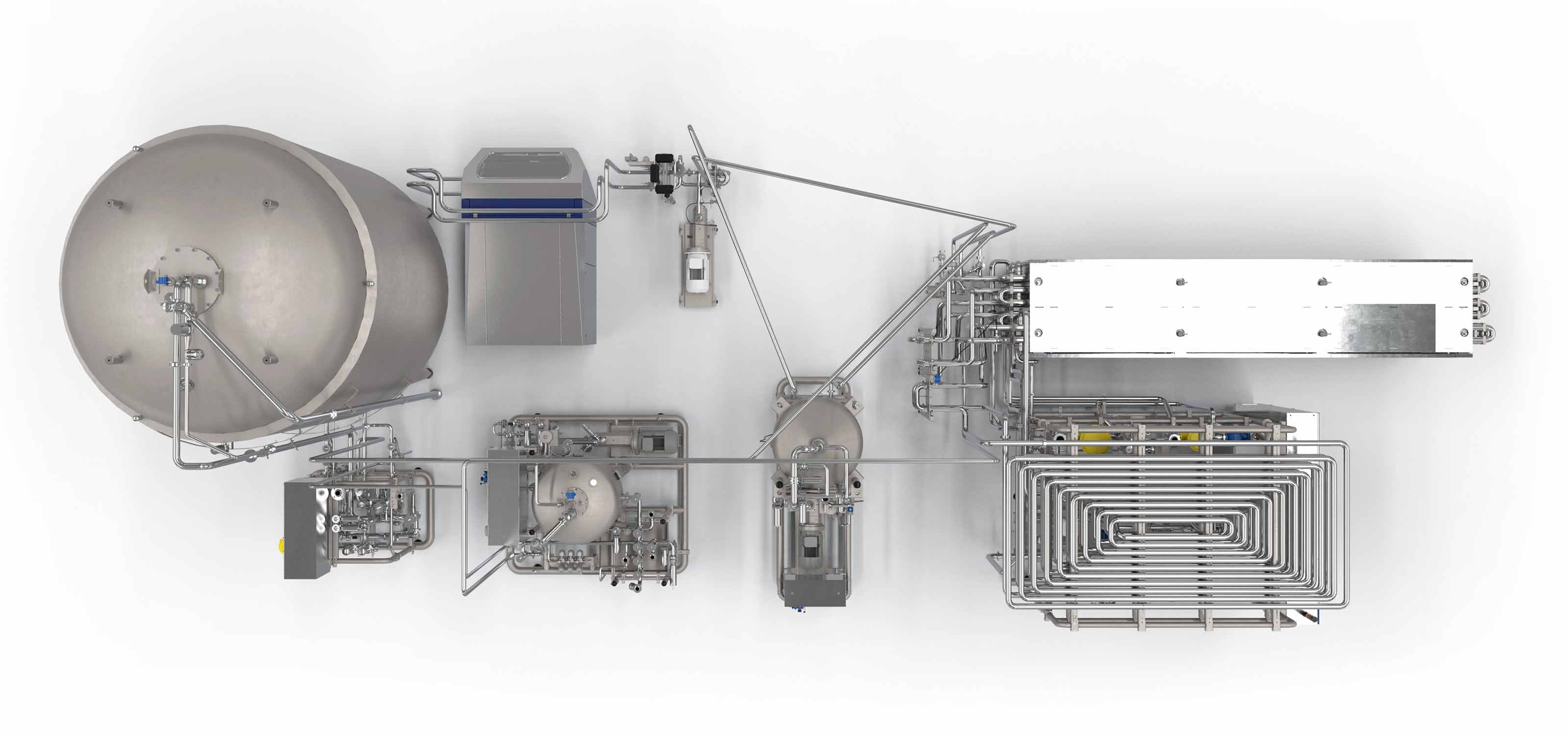

Heat exchanger

Depending on product requirements:

- Plate heat exchanger

- Tubular heat exchanger with cross-corrugated tubes for less thermal impact

Alternatively: Direct heating

Module for media supply

Decoupling of the downstream process for stable production conditions

VarioStore tank system for aseptic lines

- Vacuum-sealed and pressurised up to 6 bar

- Fully aseptic, automatic valve manifold between UHT system and buffer tank

- With integrated system for sterile gas filtration

Krones VarioSpin product deaerator

Deaeration with patented swirl infeed nozzle:

- Ensures that gas bubbles will quickly escape from the product

- Reduces oxidative impact such as loss of vitamins or discolouration of juices

Service module

- Energy supply for product heat exchanger

- Electrical and pneumatic controller with MCC and Krones HMI

Generally speaking, a dairy is completely free to choose the components and systems it needs, as Milkron will also integrate products from other manufacturers.

Components

Equipped for all packaging scenarios

For a longer shelf-life, dairy products must be packaged in light-protected containers. Good gas barrier properties and photostability make PET an excellent material choice. Krones’ container design experts can help determine which PET variant is ideal for any given end product and will also help design the bottle.

Advantages with the use of PET containers

- Maximum product safety:

- Good gas barrier

- Light protection either by the PET container itself or by the full-body sleeve

- Versatile and individual options with the design of the PET container and label

- Low weight: Saves costs during the transport and is environmentally-friendly

- User-friendly packaging variant

- Unbreakable material

- Reclosability without leaking

- Easy handling: Cap without separate sealing film

The right filling process for each product

Krones delivers the filling and packaging technology, giving milk processors a variety of filling systems to choose from depending on the product.