When you’re going through East Saxony, you can’t help feeling you’re on a country outing as you pass fields, meadows and small copses, with soft rows of hills lining the horizon. An industrial estate is probably the last thing you expect to find here – until the road sweeps left one more time, revealing one of Europe’s most modern dairies.

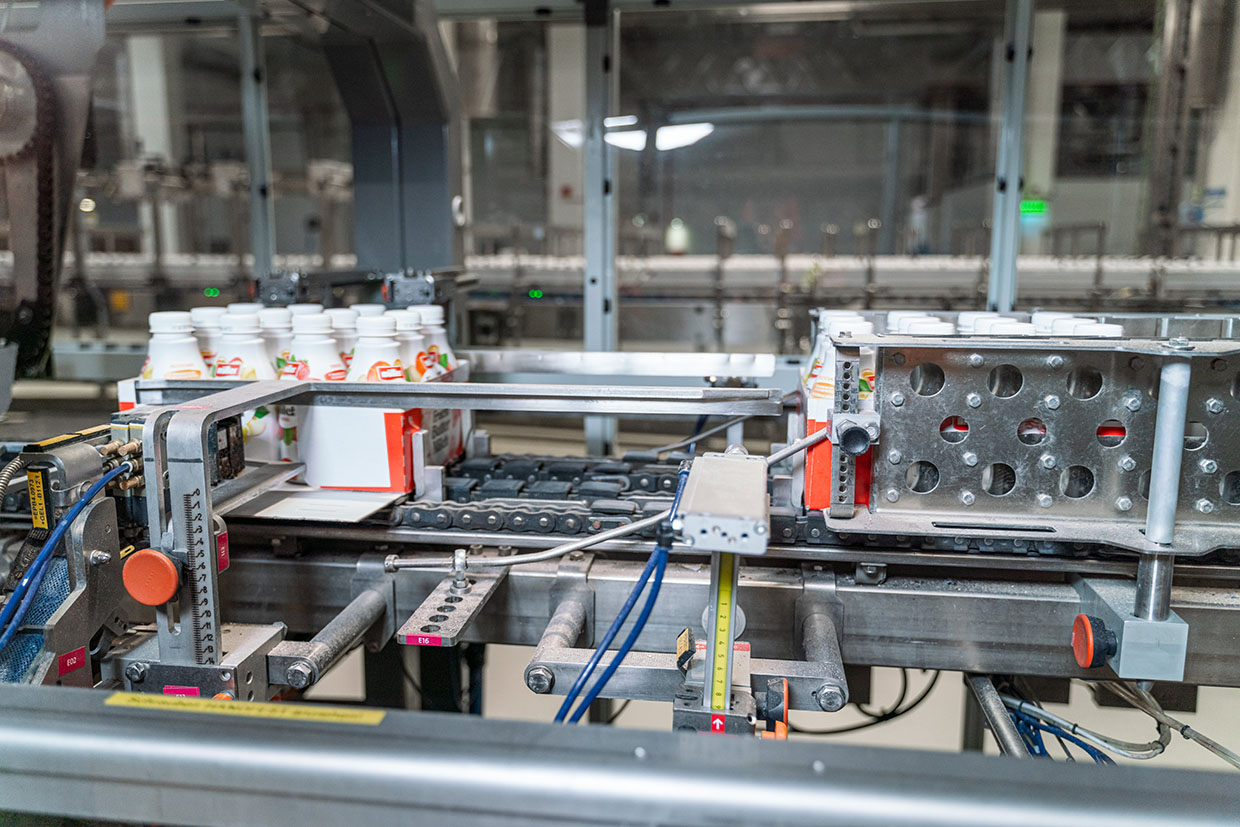

In 2004, the dairy Sachsenmilch GmbH put an aseptic four-colour filler into operation. But it wasn’t just any old four-colour filler: It was the very first of its kind built by Krones. Over 15 years and 100,000 operating hours later, the machine is still in the pink of condition, thanks to a sophisticated maintenance concept that leaves nothing to chance.

Beautiful scenery outside, high tech inside

With an area of 63.2 hectares, the Sachsenmilch premises are nearly as large as some of the small towns nearby. The company is also a boon to those towns, providing 3,000 jobs and thus playing a crucial role throughout the region. Its present facility in Leppersdorf near Dresden was opened in 1995 and has been continually expanded since then. “In the 20 years I’ve been with Sachsenmilch, there hasn’t been a single day without a building site somewhere,” says “Freshness 2” production manager Oliver Schmidt, laughing. And his colleague Jens Wenzel, the head of “Freshness 2” bottling line maintenance, adds with audible pride: “New buildings, new lines – the factory has never come to a halt. It keeps on making big strides, not least as far as technology is concerned.”

The result of the dairy’s enthusiasm to invest in new kit are 27 production and filling lines for liquid and high-viscosity products, including milk and milk-based mixed drinks, yoghurt, kefir, rice pudding and semolina pudding. The company’s three cheese-making facilities produce mozzarella, sliced cheese and sour milk cheese, all of which are packed on a total of 23 packaging lines.

Four spray towers for producing protein and calcium as well as four fluidised-bed dryers for lactose are used for the milk’s finishing treatment. Ultra-fine-tuned interaction of products, technologies and processes is instrumental in assuring that almost nothing of the 1.7 billion litres of milk supplied annually is lost. To give you two examples: The whey, a byproduct in the cheese-making facilities, is used to obtain high-quality protein powder, and the residual sugars that are no longer food-grade are processed into bio ethanol.

This systematic focus on making optimum use of the raw materials supplied is also reflected in the maintenance concept for the filling kit. Following a plan drawn up in meticulous detail, all components susceptible to wear are removed at predefined intervals and overhauled. Periodically conducted inspection routines during ongoing operation prevent unforeseen product losses. And the time anyway needed for line cleaning is also used for making minor repairs. “Our maintenance plan was specifically developed to match our requirements and assures a maximally efficient production process with minimal downtime,” emphasises Pierre Göhring. “A welcome side-effect of it all is that we extend our lines’ useful lifetime.”

A good deal of excitement

The latter is demonstrated not least by an aseptic line from Krones, which was commissioned in 2004 and has meanwhile clocked up more than 100,000 operating hours. Its heart is a four-colour filler able to fill up to four different products simultaneously. Back then, it was a prototype specifically developed for Sachsenmilch. Both companies have benefited in equal terms from this project to this very day, as Jens Wenzel confirms: “The four-colour filler was the first of its kind in the dairy sector at that time. With it, we laid the cornerstone for a mutually supportive relationship which we’ve fostered and expanded for 20 years now.”

One of its crucial constituents is close cooperation with the Krones service support team. “We’re running a 24/7 production here in Leppersdorf, and that is why we depend on high system availability,” emphasises Oliver Schmidt. In order to ensure that, the entire line is shut down for one week each in spring and in autumn for maintenance purposes. Despite the meticulous care that goes into planning the deployment of the service engineers, “each time they actually turn up here, there’s a good deal of excitement,” says Jens Wenzel, laughing. “The biggest highlight though is when production is started up again one week later.”

The aseptic line has already gone through a great number of these scheduled maintenance weeks – and there is every indication that a lot more will follow in future. “No matter which assemblies and components are needed at any given time, Krones supplies them to us without delay. They do this even though we’re talking an availability period of nearly 20 years here,” says Jens Wenzel. “And in the rare case that a certain spare is actually no longer available, they promptly offer us alternative solutions or upgrades.” He adds that all of this has over the years evolved into a close bond between the two companies: “I think the teamwork between Krones and our dairy is excellent. No matter whether it’s day or night: We invariably get the support we need.”

No matter which assemblies and components are needed at any given time, Krones supplies them to us without delay. They do this even though we’re talking an availability period of nearly 20 years here.

Jens WenzelHead of “Freshness 2” bottling line maintenance

Jens WenzelHead of “Freshness 2” bottling line maintenance

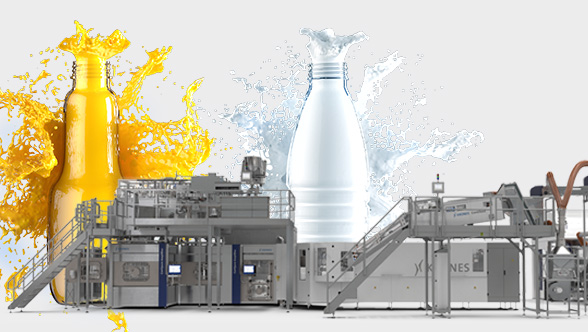

Another aseptic block, another prototype

When the dairy was faced with the need to add more aseptic capacity in 2019, Krones came knocking with yet another prototype, the most recent upgrade of the dry-aseptic blow-moulder/filler block this time – and Sachsenmilch went for it yet again. The features distinguishing it from the preceding model Contipure AseptBloc DA include the cleaning concept which uses hot caustic for the machine’s surface and steam for the paths coming into contact with the product, which makes for shorter sterilisation times and higher system availability. The filler installed in the new block is again a four-colour machine. The 15 years of development since the first prototype was commissioned have yielded many improvements. “The servo technology now installed can be checked, monitored and controlled while operation is ongoing,” says Pierre Göhring. “And automatic adjustment of the handling parts provides substantial time savings in make-ready and also significantly reduces physical stress for the staff.”

Contipure AseptBloc DA

- Space-saving combination of blow-moulder, filler and capper

- Gentle, dependable filling of sensitive products

- Preforms and caps are sterilised by means of hydrogen peroxide (H2O2)

- 360-degree preform treatment: inside, outside and in their neck area

- Short cleaning times make for high availability levels

The scope of delivery also included two Sleevematic labellers and a Variopac Pro T which packs the labelled containers onto trays. Milkron was responsible for linking the new four-colour filler up to the process-engineering kit, which also contained a device for culture dosing, a yoghurt cooler and a fruit-mixing station.

The line has been running at a speed of 36,000 containers an hour since 2021. And even though it still has quite a bit to go to reach the 100,000 operating hours clocked up by the first line, one thing is certain: The line is in safe hands at Sachsenmilch. The dairy will make sure it reaches this benchmark in the pink of condition.

Brief portrait of Sachsenmilch

- Founded in 1990, since 1994 a subsidiary of the Theo Müller group of companies

- Located in Leppersdorf near Dresden (opened in 1995)

- Payroll of 3,000

- Product portfolio ranging from milk and milk-based mixed drinks, butter, yoghurt and cheese right through to rice pudding and other desserts

- Capacity: The annual volume of milk supplied to and processed by the company is around 1.7 billion kilograms.