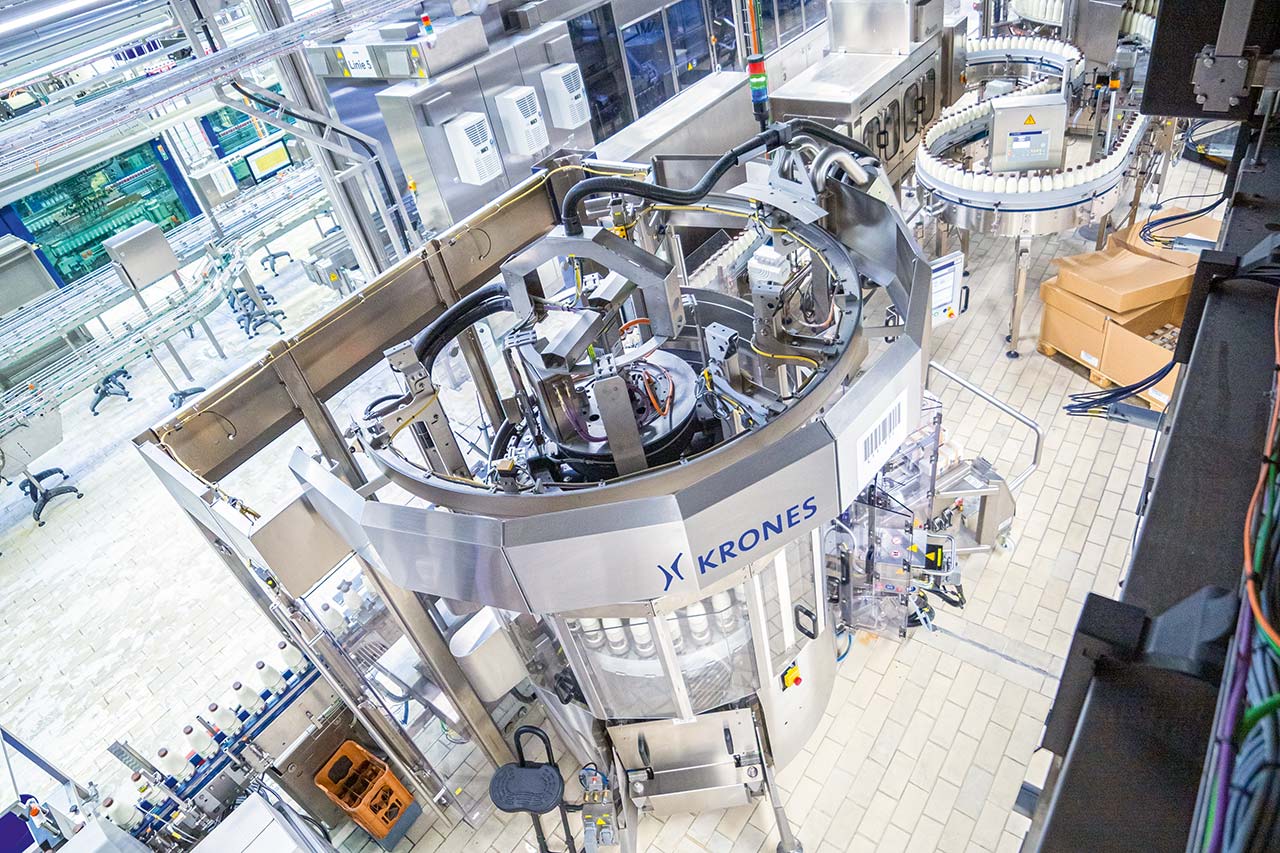

Krones became familiar with Gropper’s untiring pursuit of innovation and willingness to take risks back in 2004, when the dairy decided to move into PET packaging. The company had very specific ideas about how its first PET line should be equipped. They wanted to use a two-color filler with dry-aseptic technology. Since Krones didn’t have that type of filler in its portfolio at the time, the Neutraubling-based company delivered just a Contiform stretch blow-molder and a two-color sleeve labeler that was designed especially for Gropper.

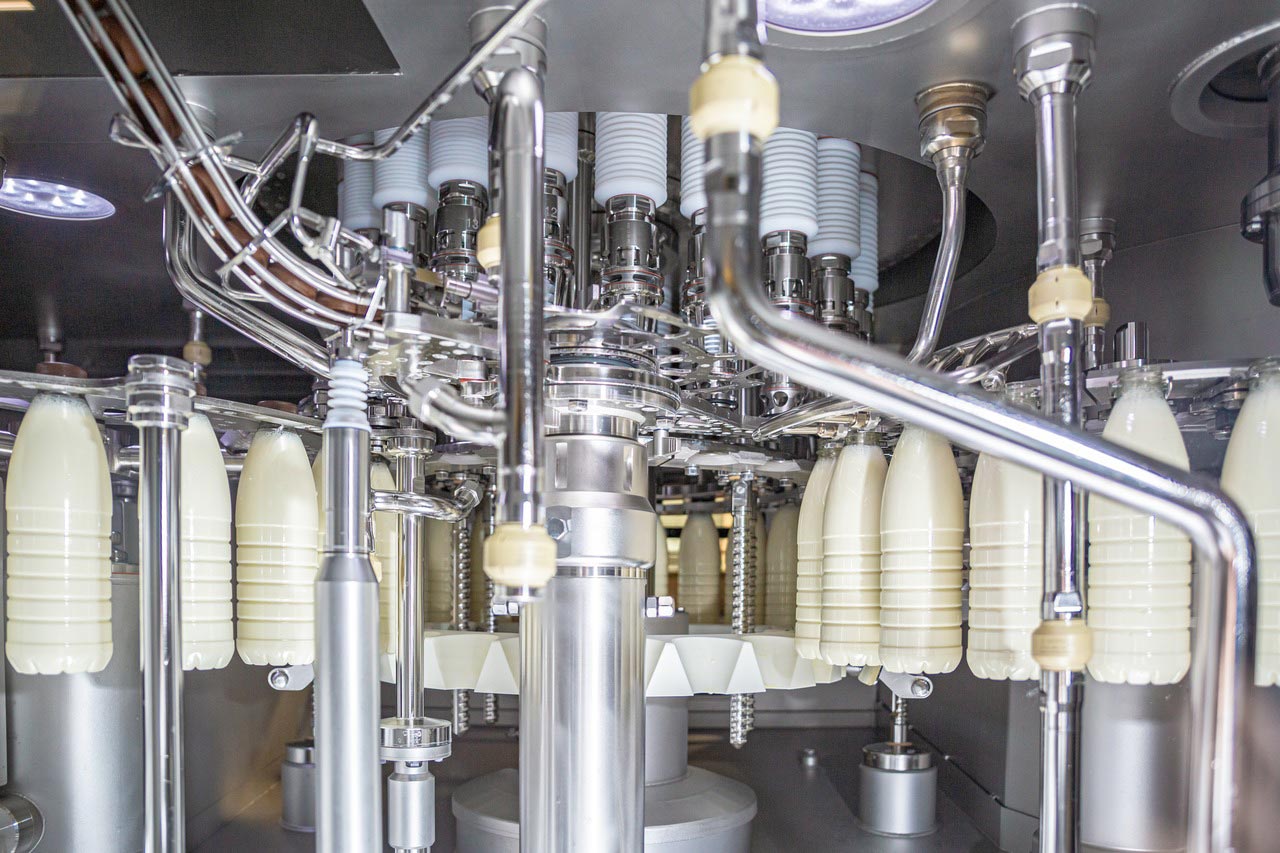

But Krones’ filling technology experts had taken the customer’s idea as inspiration and developed a four-color filler that uses gaseous hydrogen peroxide to sterilize the containers and caps. And their efforts paid off. In 2005, when Gropper was considering its next investment in a PET line, the company chose this newly developed filler from Krones. “It was still just a prototype – so of course, there were some ups and downs,” recalls Berthold Burgmeier, Head of Engineering. “When we were looking to add yet another line in 2012, we weighed very carefully whether we should go with Krones again. In the end, though, we realized that Krones had continually improved its dry-aseptic process in the meantime – and so we did. Right now, nobody else on the market can build a dry-aseptic PET line at the same level of quality and reliability.”