“Usually, that type of vegan product consists of protein sources such as peas, beans or soy. What a lot of people don’t know is that, in Europe, it is not mandatory to declare the ingredients’ origins. Therefore, many consumers do not realise that the basic ingredients often are not produced locally but imported from Asia and then processed here in Europe. I don’t consider that very sustainable,” says Christoph Nyfeler, managing director at Circular Food Solutions Switzerland AG. And it’s precisely this situation that the start-up team is addressing: They want to make meat substitutes more sustainable, starting by drastically changing their choice of raw materials. “We use an existing protein source that we purchase locally and adapt to our own vegan product range,” explains Christoph Nyfeler. And that takes us back to this article’s starting question: The protein source locally comes directly from the Chopfab Boxer craft brewery based in Winterthur.

What do burgers and beer have in common? As far as culinary pleasure goes, plenty of people will doubtlessly agree they are a perfect match. But for flexitarians, vegetarians and vegans who eat meat substitutes, beer and vegan burgers go equally well together. And for some time now, that has proved true not only at the table but also already during production. You see, the start-up Circular Food Solutions Switzerland has adopted a revolutionary approach based on upcycling brewer’s grains, so that they can be used to produce meat substitutes.

Anyone who has taken an in-depth look at the brewing process knows that one of its by-products is brewer’s grains, a material that is often underappreciated. It is mostly not used further even though it contains plenty of valuable proteins, which render it ideal for food production, as Christoph Nyfeler tells us: “In some cases, spent grains are sold to bakeries or the baked-goods industry. But most breweries don’t tap into that great potential and merely sell them to livestock farmers as animal feed. But brewer’s grains do in fact offer so much more.” And Circular Food Solutions not only reveals that hidden potential but also makes full use of it.

One of a kind worldwide

The start-up’s team set to work in precisely the place where brewer’s grains are produced: the brewhouse. Once the mash has been separated, the spent grains are passed from the lauter tun directly into a further vessel, the disperser, with two mills linked up to the latter. “We’ve joined forces with Steinecker to develop a dedicated recirculating system, which serves to pass the spent grains repeatedly through the disperser and the mills, thus grinding them to an ever finer structure.” That’s how Christoph Nyfeler describes the process, and Matthias Pohl from Steinecker’s sales team adds: “Our Phoenix BMC project has enabled us to gain valuable experience with brewer’s grains, and how they can be upcycled in this first important step. Of course, these insights have been put to good use in our job for Circular Food Solutions and successfully translated into shopfloor reality.”

Once the targeted fineness has been reached, the ground grains are first temporarily stored in buffer tanks (likewise supplied by Steinecker) and then extruded. “This wet-extruded material produced from brewer’s grains is one of a kind worldwide,” says Christoph Nyfeler with a distinct note of pride. “It’s the basis for any conceivable form of meat substitutes.”

To this end, Circular Food Solutions prepares the extruded material for further processing in line with the customer’s wishes and recipe by mixing the spent grains with another protein concentrate, water, aroma compounds or salts for example. Once this base material has been turned into the final product, it is dispatched chilled to the customer who then uses it to make not only burger patties but also strips or mince – all of it plant-based, of course. “Circular Food Solutions is a purely B2B operation. Our sole focus is on developing products and on the technology needed for making them,” explains Nyfeler. “Turning our base material into the food that consumers will find in the supermarkets’ refrigerated display cabinets, that’s our customers’ job.”

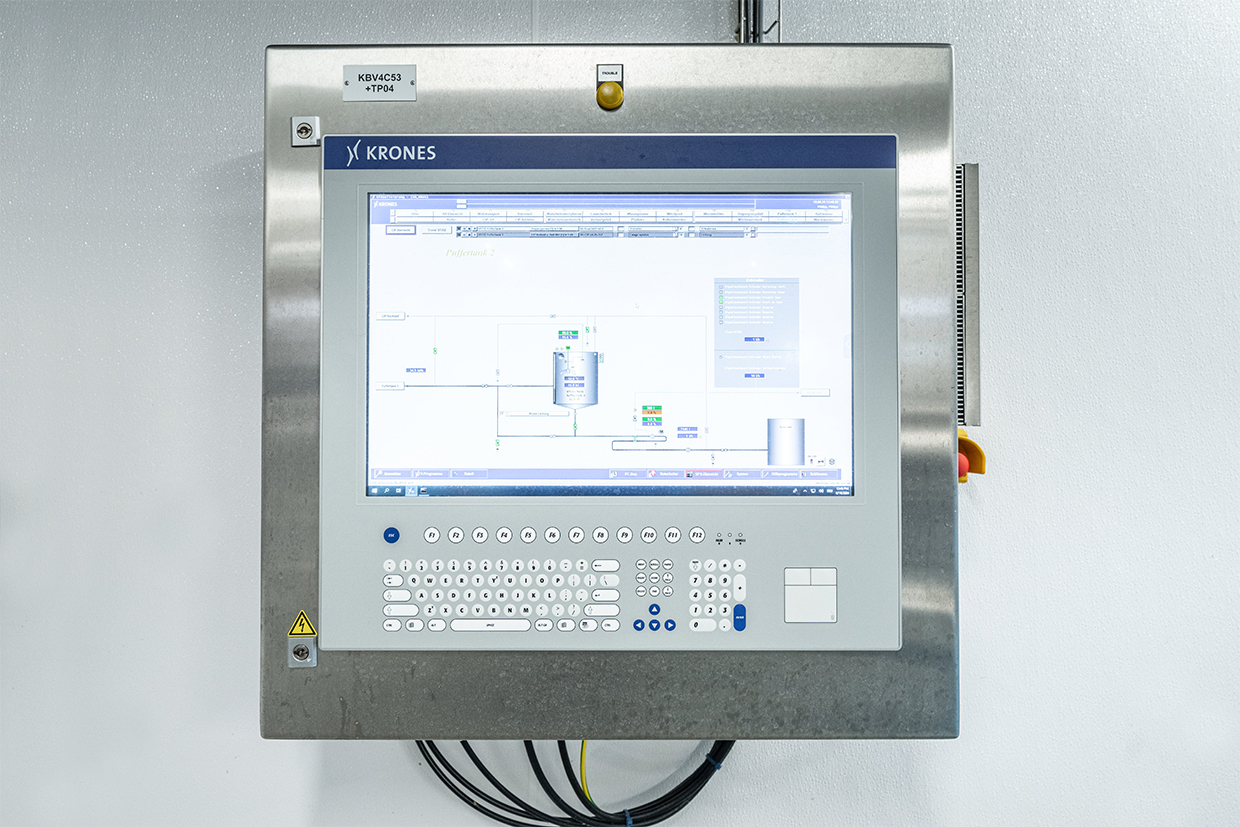

Botec F1 process control system

But why did the start-up’s team decide to set up its production process directly in the brewhouse? For a number of reasons, first and foremost because microbiological safety is of vital importance, as Matthias Pohl explains: “You see, the company’s concept uses spent grains as a natural raw material for food, for which the hygienic requirements are significantly higher than for animal feed. For this reason alone, it is best to process the brewer’s grains with the requisite rigour directly in the brewery. It is, of course, also conceivable for the start-up to build its own processing plants. But that would entail elaborate logistics and intricate cold chains in order to ensure the requisite level of microbiological safety which is absolutely vital.” It is not only the advantages on the logistics side, though, that are cogent arguments in favour of integrating the production process into a brewery’s operation, as Matthias Pohl points out: “You see, all of the peripherals required for media supply and CIP cleaning are already in place here and can of course be easily modified, so that they can also be used for the spent-grains upcycling process.”

That is why the scope of Steinecker’s order for this holistically conceived concept subsumed not only part of the systems technology but also the line’s integration into the Botec F1 brewing-process control system already in place at the Chopfab Boxer brewery. “The benefits for us here at Circular Food Solutions are that we can fine-tune the brewing and upcycling processes for a perfect match because thanks to Botec we know exactly when a brew is finished and fresh spent grains are available. That enables us to combine our production sequences to optimum effect,” says Christoph Nyfeler. This planning reliability is important because it is imperative that the spent grains are processed as promptly as possible after lautering in order to guarantee food safety. What’s more, Botec F1 provides the requisite transparency to ensure complete traceability of each production batch.

Successful premiere on an industrial scale

Circular Food Solutions made its first products in early 2024. “I must admit that we had some ambitious goals and a comparatively tight timeframe for a process that didn’t even exist. Bearing that in mind, I can tell you this: We’re very satisfied with this system set-up,” says Christoph Nyfeler. “Needless to say that everything looks somewhat different on paper than it does on the shopfloor. And to make sure the system actually yields the results you had in mind when you started, you will have to fine-tune and optimise it at one point or another during ongoing operation. But that’s why we’ve brought partners on board who can draw upon experience in both systems engineering and in the brewing and food industries.”

The “ambitious goals” mentioned above also become manifest when you look at the system set-up installed. Even though Circular Food Solutions has only been active in its chosen market for a few short months, its list of customers already includes one of Switzerland’s leading private-label manufacturers. “That has validated our approach and confirms we’re on the right track,” says Christoph Nyfeler. “And we’re confident that it offers much, much more potential. It was for this reason that we invested in a large-capacity production line with a high degree of automation right from the start.”

Multiplying this concept to tap into further markets

And even though Circular Food Solutions is currently serving solely the food industry, the managing director has a lot more ideas. “The showcase line we’ve developed here in Winterthur can just as well be translated into shopfloor reality in other breweries,” he says. “Of course, some basic prerequisites will have to be met there as well, like a certain amount of spent grains, for example, to make sure that such an upcycling system can be run continuously, for optimum cost-effectiveness.”

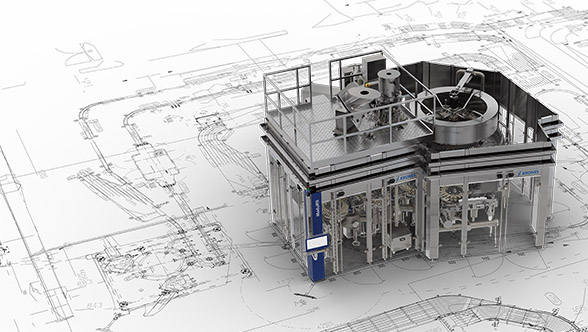

And because the decision-makers at Circular Food Solutions had identified that opportunity at an early stage, they already set great store by designing a multipliable solution when the concept and technology for the new process were developed. To this end, the footprint of the system itself was kept as small as possible, so that the set-up can also be implemented in breweries where space is at a premium. That is because Christoph Nyfeler has a clear vision: to further increase the number of vegan meat-substitute variants on offer. “Demand for meat substitutes is soaring. And in our view, spent grains are one of the most sustainable basic ingredients, ideally suited for increasing regional sourcing of ingredients for vegan products, thus improving their sustainability.”

New but not novel food

Since the brewer’s grains used for making the meat substitutes are harvested and used as a whole (not just parts of them) and their production process does not subject them to either chemical or enzymatic treatment, the raw material is not regarded as a novel food. That means the spent-grains-based meat substitutes can be offered in the retail trade without restrictions, provided of course that national laws and ordinances and the relevant requirements for mandatory labelling are all complied with.