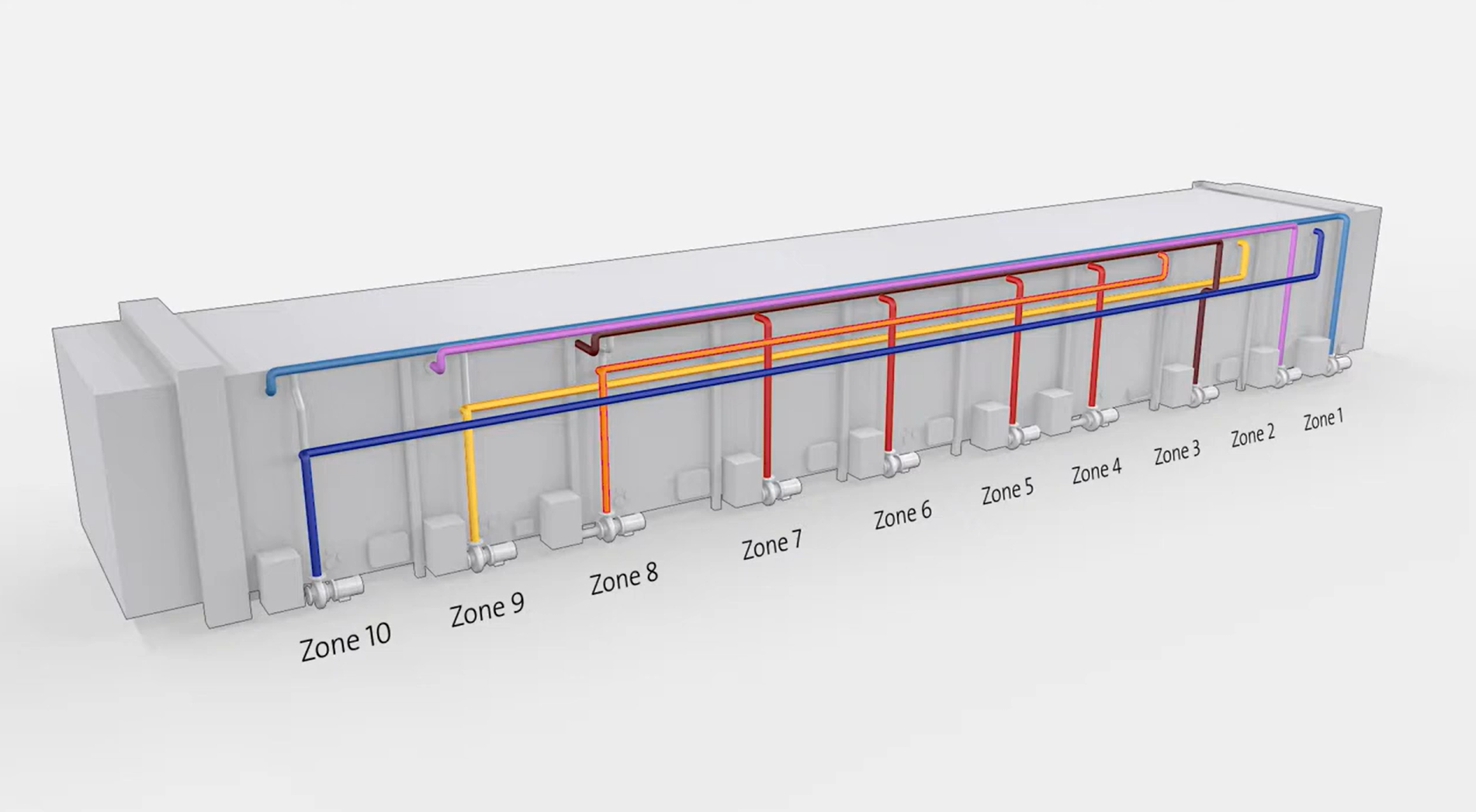

How to benefit from the latest technical advances? Upgrades are one option – and the Krones’ Lifecycle Service team (LCS) proves that point every time they retrofit a relatively old machine with suitable upgrade packages. And that pays dividends for the line owners, in the form of improved levels of efficiency and product quality, for example, as well as energy and water savings. What’s even more, the eco-footprint is many times smaller than that of a new machine. “When we update a pasteuriser’s process technology, its sturdy stainless-steel housing, conveyor belts and spray systems are retained. That saves plenty of new steel and the associated CO₂ emissions for production and transport,” says Jan Golm from the LCS team, adding: “Ten or twenty years ago, machine housings were made of steel sheets with a thickness of over one millimetre, an ample amount by today’s standards. These housings were made to last, and it would certainly be a waste to replace them.”

By the way, this very LCS team has just successfully completed an elaborate, large-scale upgrade project, comprising extensive retrofit jobs on no less than four pasteurisers for the Turkish brewery Anadolu Efes. “We more or less completely disassembled the machines, removing nearly every part. And when customers see their machines gutted like that, they definitely need to have a fair bit of confidence in our ability to get them up and running again,” says Jan Golm. He goes on to emphasise: “We’re really grateful to Anadolu Efes for their high degree of trust in our company and the excellent teamwork.” Orkun Öztekin, the head of Krones Sales and Marketing in Türkiye, played a significant role in this context. To quote Jan Golm: “At start of his career, Orkun used to be an electrical maintenance engineer at an Anadolu Efes Brewery and has, therefore, achieved to perfectly translate all our technical questions and concerns into both languages and cultures. That was an enormous boon to our work, making it a whole lot easier.”

“When we update a pasteuriser’s process technology, its sturdy stainless-steel housing, conveyor belts and spray systems are retained.”

Jan GolmKrones Lifecycle Service

Jan GolmKrones Lifecycle Service