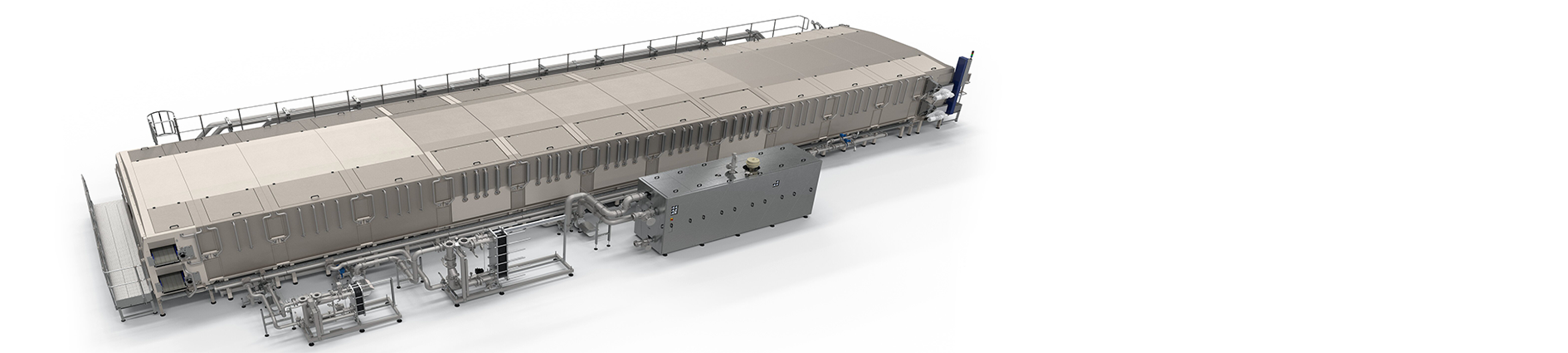

Highly efficient pasteurisation

Better safe than sorry

Product safety is a core issue in marketing your beverage. Pasteurisation is often the number one method when it comes to the preservation and stabilisation of freshly filled products. The LinaFlex tunnel pasteuriser offers a pasteurisation process with precise PU control and an efficient use of resources. You will get a pasteuriser that is specifically designed to meet your operational requirements.

At a glance

- Modular single-deck or double-deck tunnel pasteuriser with precise PU control system

- Main conveyors are exactly adjusted to suit the container characteristics and production conditions

- Quick installation

- Integration of long-lasting components

- Integrated monitoring of the process and product quality

The Design

Three machine variants and their features

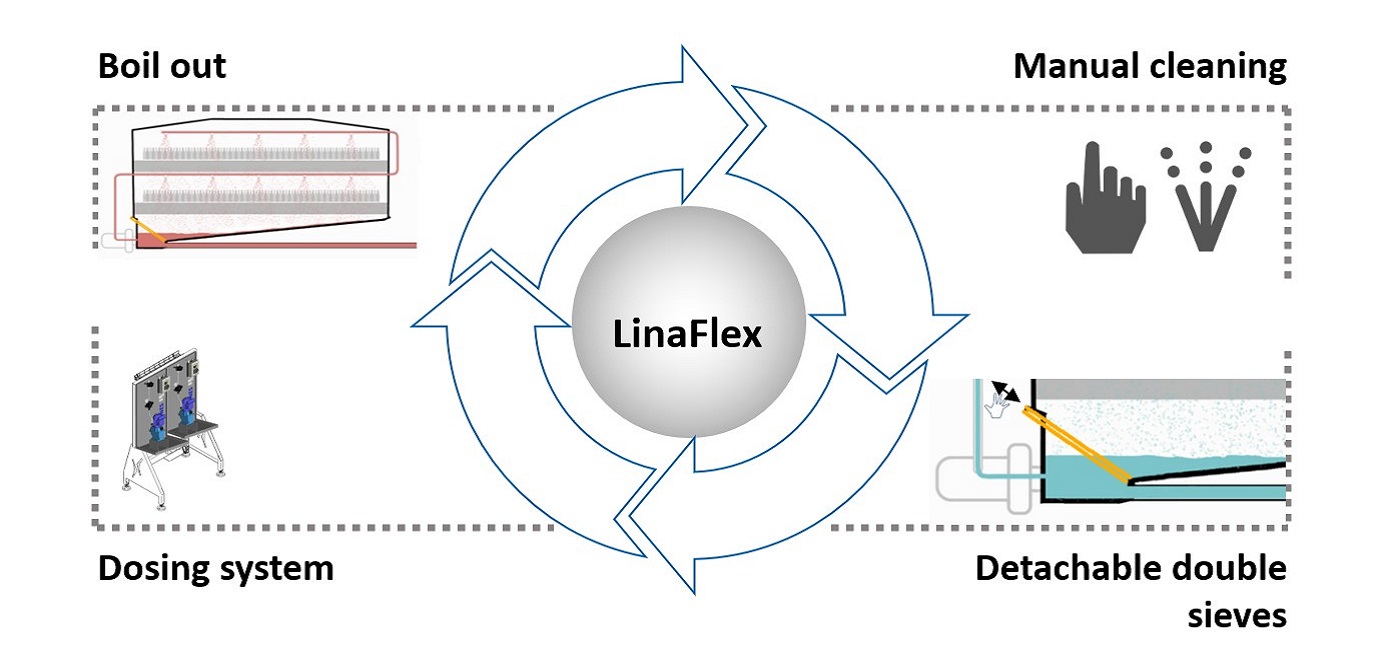

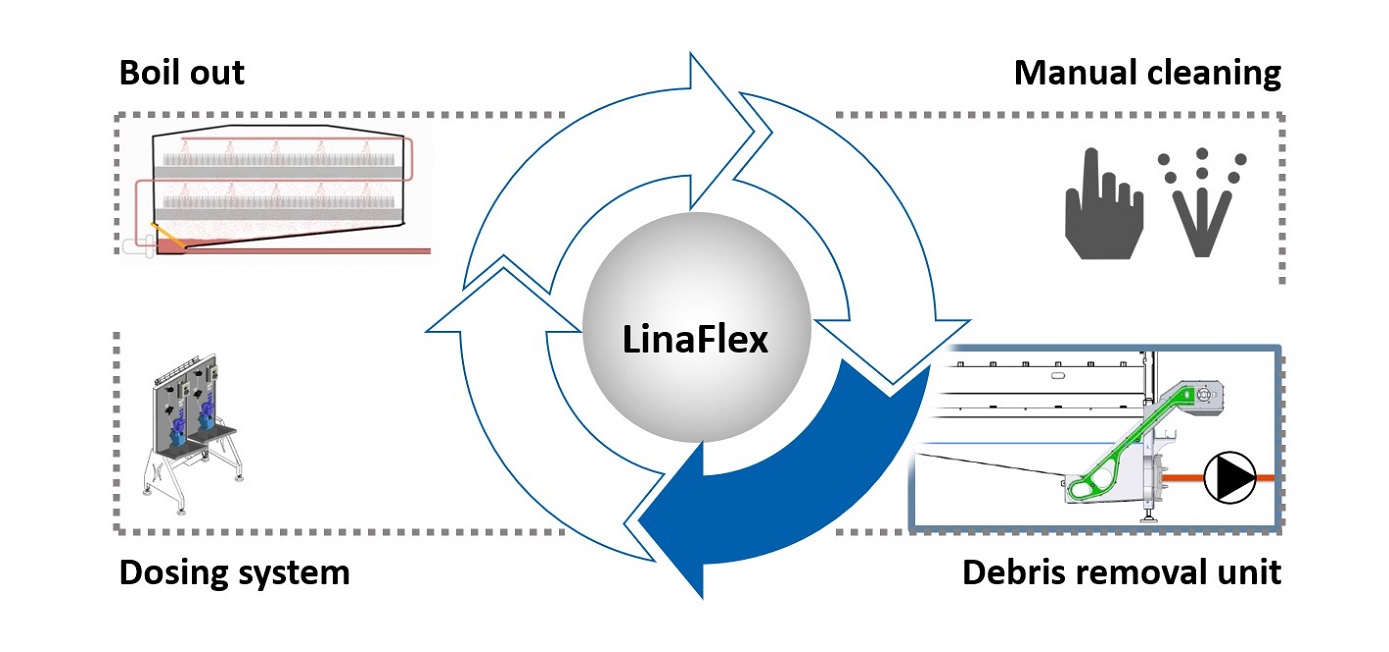

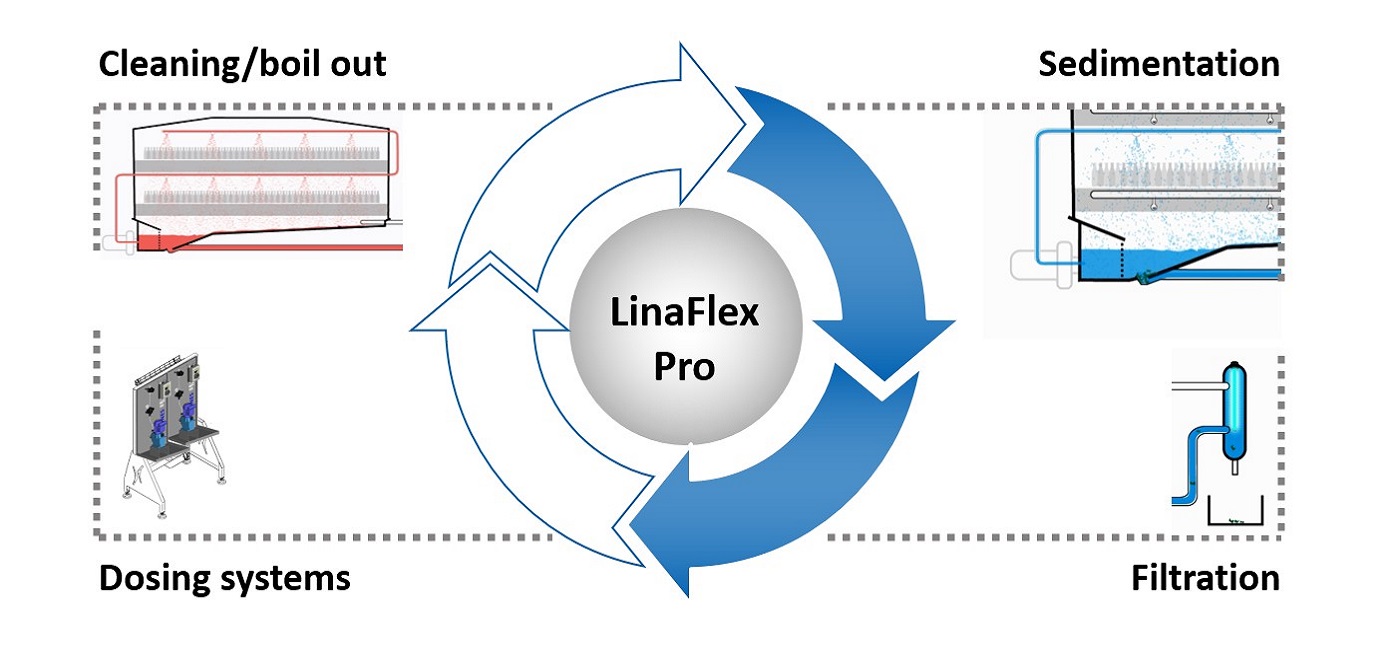

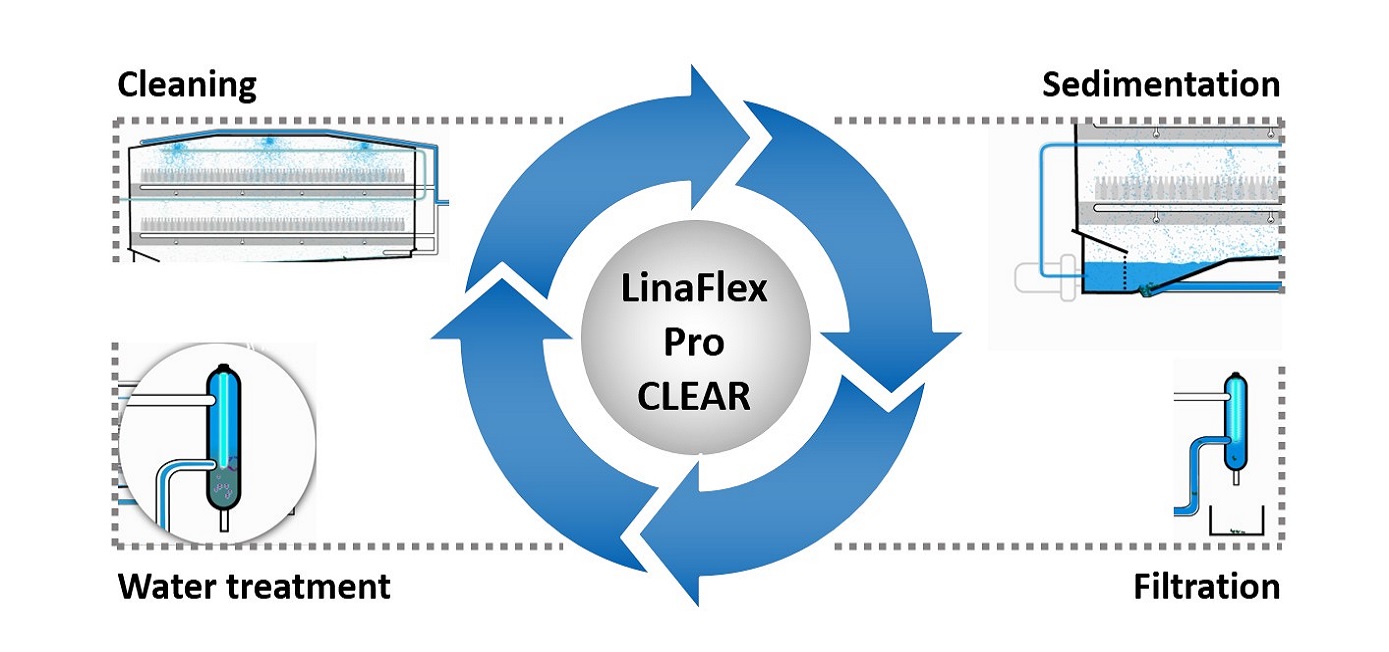

Options for internal cleaning and hygiene in the machine

| Feature/Machine variant | LinaFlex | LinaFlex Pro | LinaFlex Pro with CLEAR system |

| Boil out | ✓ | ✓ | ✓ |

| Detachable double sieves | ✓ | X | X |

| Sieving conveyor in zone | optional | X | X |

| Sedimentation and filtration | X | ✓ | ✓ |

| Dosing system (standard) | ✓ | ✓ | ✓ |

| UV water treatment | X | X | ✓ |

| ClO2 water treatment | optional | optional | Recommended |

The concept

- LinaFlex pasteuriser in modular basic design

- Integration of all basic components such as PUC4, Marathon Belt or Ironman Belt

What's the solution for cleaning and hygiene of the LinaFlex?

- Boil out of the housing and manual cleaning procedures

- Removal of particles and contamination using detachable double sieves

- Manual cleaning of the detachable sieves

- Regular water changes

- Use of chemical disinfectants

The concept

- LinaFlex pasteuriser in modular basic design

- Automatic sieving conveyor in zone tank

- Effective protection of the nozzles and pumps against glass fragments

- Flushing of the conveyor into a central collecting chute

- Integration of all basic components such as PUC4, Marathon Belt or Ironman Belt

What's the solution for cleaning and hygiene of the LinaFlex?

- Boil out of the housing and manual cleaning procedures

- Removal of particles and contamination using an automatic sieving conveyor

- Regular water changes

- Use of chemical disinfectants

The concept

- Automatic removal system for glass fragments and other particles

- Individual LinaFlex Pro pasteuriser configuration with the desired LinaFlex components

- Optional: Retrofitting option for the CLEAR system

What can the LinaFlex Pro removal system do?

- Reliable extraction and removal of particles

- Reliable protection of the nozzle system against clogging

- No manual cleaning of detachable sieves necessary

- Better removal capacity as compared to filter conveyor systems

The concept

- Integration of the CLEAR system

- Individual LinaFlex Pro pasteuriser configuration with the desired LinaFlex components

What can the future-oriented CLEAR hygiene system offer?

- Continuous cleaning and treatment of the water

- Reliable extraction and removal of particles

- Limitation of biological growth in the pasteuriser

- Cleaning of surfaces

- Safe protection of the nozzle system against clogging

- Recommended with highly efficient CLO2 dosing system

Benefits to you

Maximum product safety

The third-generation PU control system ensures maximum product safety and a constant product quality dynamically and in real time.

Best hygienic conditions

The clean design enables optimum cleaning with minimum personal requirement.

High resource efficiency

The LinaFlex excels with regard to numerous energy saving aspects:

- Optimised water volumes thanks to integrated zone tanks

- Up to 20 % reduced energy consumption during heating

- Low consumption of chemicals and energy

- The drive output per deck is 0.75 kW

- Full insulation as an option for a reduction in emission losses of up to 60 %

Low maintenance required

Maintenance and service costs are reduced as readjusting the tension and replacement of wear strips are no longer required.

Conveyors with a long service life

The conveyors have an efficiency of at least 98 % and a service life of up to 20 years Thanks to a four times increased service life, up to 25,000 euros a year can be saved.

Fully automatic product change-over

The product change-over with sweeper is performed automatically and includes an automatically adjustable blower as an option. Thereby, the machine can be changed over to new types within less than 10 minutes*.

* Depending on the zone configuration

Benefits of the enviro-classified LinaFlex?

Energy efficiency

- Design exactly tailored to suit the production process

- Optimum thermal insulation: Complete insulation for reduced heat losses

Media efficiency

- Measuring systems for media consumptions

- Media monitoring (steam, water, power and air) by the virtual pasteuriser

Environmental compatibility

- Gear oil, grease and chemical dosing according to enviro criteria