Fully automatic change-over system for blow moulds

Classical handling parts change-over is quite time-consuming: Blow mould change-over often takes up to an hour and requires one and sometimes even two operators. The manual activity, however, increases the fault potential which, in the worst case, may affect the following production negatively. To accelerate change-over to another bottle type, Krones has developed the MouldXpress Robot, an automatic change-over system.

At a glance

- Fully automatic change-over system for blow moulds

- Fault-free change-over process thanks to the use of a robot

- Very fast blow mould change-over at record speed

- Clear assignment of the correct blow moulds thanks to RFID tags

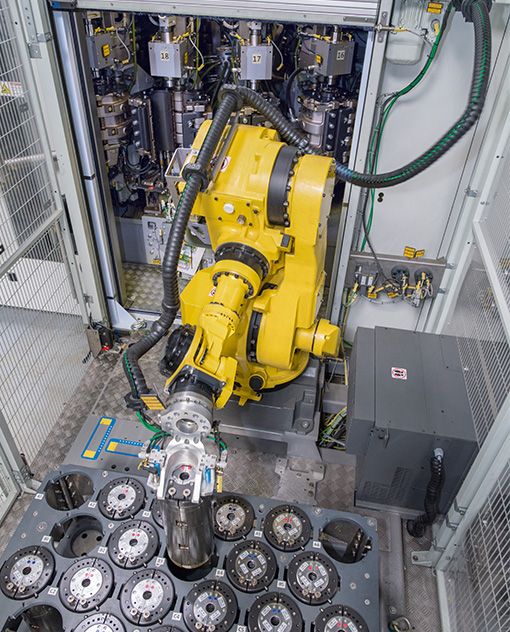

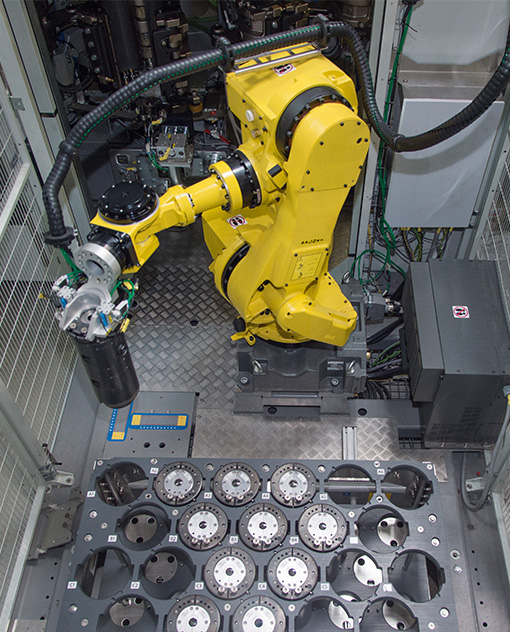

The MouldXpress Robot carries out a complete blow mould change-over without operator intervention.

And that's how it works:

- Once the change-over process has been started, the blow moulder automatically places the next blowing station in position, opens the machine guards and releases the mould in the blowing station.

- The robot takes a complete blow mould package (both halves and the base mould) and positions it in an empty mould magazine. Afterwards, it picks up the new blow mould and inserts it in the blowing station. The blow moulder interlocks it afterwards.

- The operator only has to move the magazine with the moulds into the operating range of the robot prior to the change-over process and remove it again afterwards.

The MouldXpress Robot carries out a complete blow mould change-over without operator intervention.

And that's how it works:

- Once the change-over process has been started, the blow moulder automatically places the next blowing station in position, opens the machine guards and releases the mould in the blowing station.

- The robot takes a complete blow mould package (both halves and the base mould) and positions it in an empty mould magazine. Afterwards, it picks up the new blow mould and inserts it in the blowing station. The blow moulder interlocks it afterwards.

- The operator only has to move the magazine with the moulds into the operating range of the robot prior to the change-over process and remove it again afterwards.

The complete blow mould change-over takes only 15 minutes.*

- The automatic process starts directly after the last bottle has left the Contiform.

- The exactly programmed motion sequences of the robot make sure that each second of the change-over process is exactly planned and that there are no downtimes.

- The automatic sequence allows for exactly adjusting the duration of the change-over process to the production planning.

- The guard area ensures quick, safe and unobstructed robot operation next to the blow moulder.

* For a Contiform with 24 blowing stations

The complete blow mould change-over takes only 15 minutes.*

- The automatic process starts directly after the last bottle has left the Contiform.

- The exactly programmed motion sequences of the robot make sure that each second of the change-over process is exactly planned and that there are no downtimes.

- The automatic sequence allows for exactly adjusting the duration of the change-over process to the production planning.

- The guard area ensures quick, safe and unobstructed robot operation next to the blow moulder.

* For a Contiform with 24 blowing stations

The use of a robot enables faultless and reproducible execution of the complete blow mould change-over.

- The robot is a well-experienced industrial robot which is ideally suited to meet the requirements of blow mould change-over.

- The exactly programmed motion sequences of the robot ensure that sequence-related faults are excluded 100 percent.

- The RFID tags of the blow moulds make sure that the robot clearly and reliably detects the required blow moulds.

The use of a robot enables faultless and reproducible execution of the complete blow mould change-over.

- The robot is a well-experienced industrial robot which is ideally suited to meet the requirements of blow mould change-over.

- The exactly programmed motion sequences of the robot ensure that sequence-related faults are excluded 100 percent.

- The RFID tags of the blow moulds make sure that the robot clearly and reliably detects the required blow moulds.

Benefits to you

Fully automatic

The moulds are changed fully automatically and without manual interventions. The operator can use this time to already attend to other tasks.

Fast

The process takes only a few minutes. A machine with 24 blow moulds, for instance, requires only 15 minutes for the complete change-over, which increases the OEE of the complete line.

Reliable

Thanks to the use of RFID tags and well-proven robot technology, the moulds are changed over correctly and reproducibly.

Flexible

The fast and reliable mode of operation of the MouldXpress Robot makes it possible for you to process more container designs than before.