Integrated preform rinser for the blow moulder

No chance for dust and other particles

Various particles such as dust, cardboard or residues from wooden pallets may settle in the preforms. The Prejet can remove them – both reliably and efficiently. Thanks to its thoroughness, this system is also suitable for aseptic applications.

At a glance

- Preform interior cleaning system

- For up to 90,000 preforms per hour

- Compactly integrated in the blow moulder infeed, it does not take up any additional installation space

- Increased product safety thanks to a high cleaning performance

- Fewer preform rejections thanks to reliable particle removal

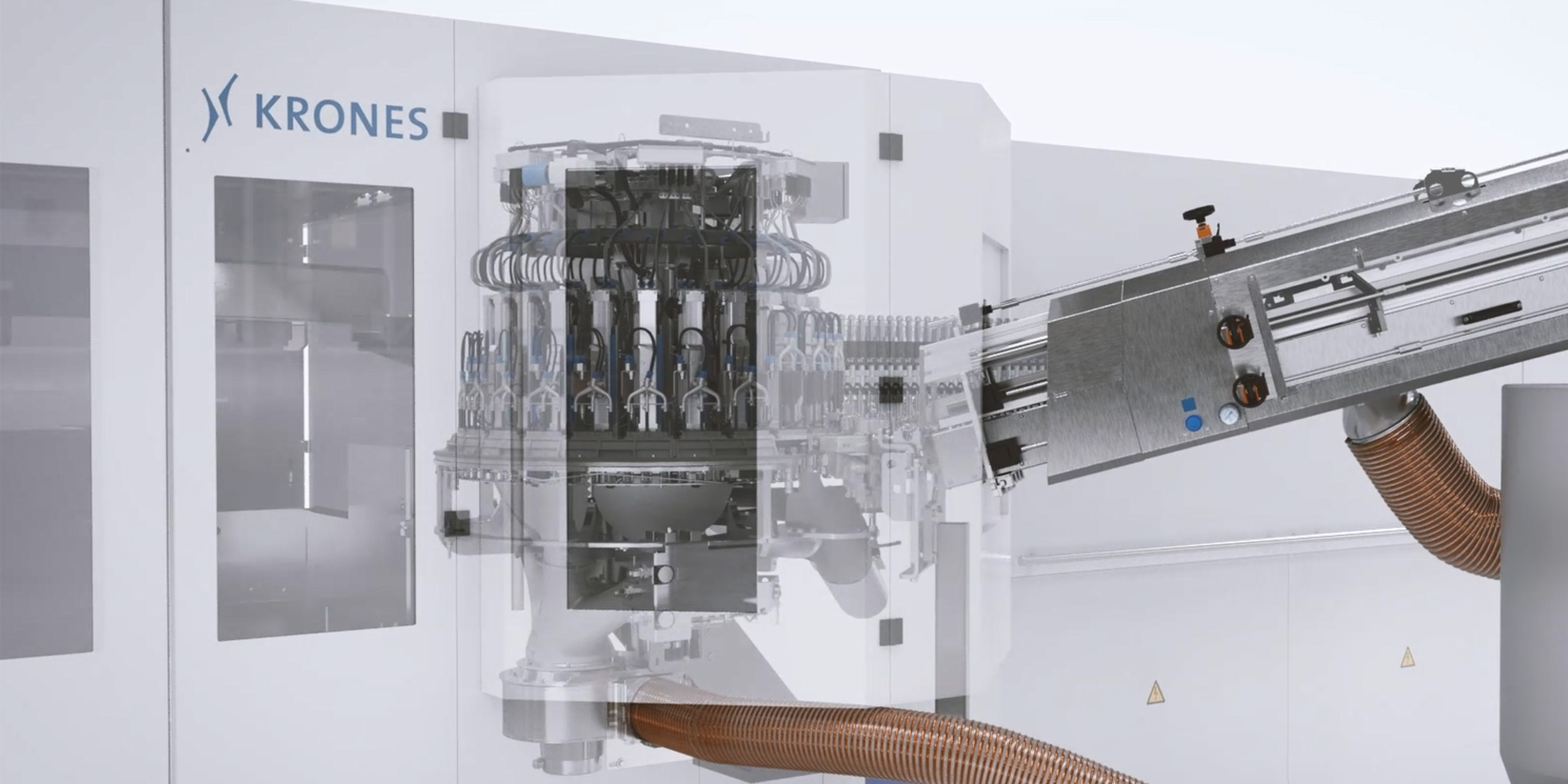

The design

The system is directly integrated in the blow moulder infeed. Therefore it’s perfectly accessible for operation.

The blow moulder infeed starwheel is simply used as rinser starwheel which prevents that additional space is required.

Infrared linear oven

Preform feed unit

Preform rinser starwheel

Variants:

- For low and medium outputs up to 44,000 preforms per hour

- For high outputs up to 90,000 preforms per hour

- Optional: downstream camera inspection units for additional safety

Benefits to you

Energy and media efficiency

During development of the prejet preform rinser, the focus was not only on the cleaning performance but also on the efficient use of energy and media. It consumes up to 50 percent less compressed air as compared to its predecessor model.

Hygiene and production quality

With its high and reproducible cleaning performance, the prejet makes sure that the preforms enter the blow moulder as free of particles as possible. The particles are effectively detached with ionised air – and simultaneously removed by suction.

Ergonomic design and ease of operation

The optimum access close to the floor enables easy change-over without tools within minimum time.