Automation played a crucial role in Coca-Cola HBC’s decision in favour of LineXpress. “The fact that fewer human interventions are required in the production process means that the risk of errors is minimised. Moreover, it makes production planning more reliable because the sequences involved can be planned more accurately” explains Theodoros Kappatos, Head of Engineering, Group Supply Chain Coca-Cola HBC. This is because LineXpress uses the material-flow-automation function to predict the materials needed for certain production cycles with absolute precision, reducing both product overflow and excessive material use.

The automation function at the individual machines and material-flow monitoring are equally important to Coca-Cola HBC, as they increase line output and efficiency and reduce non-productive times.

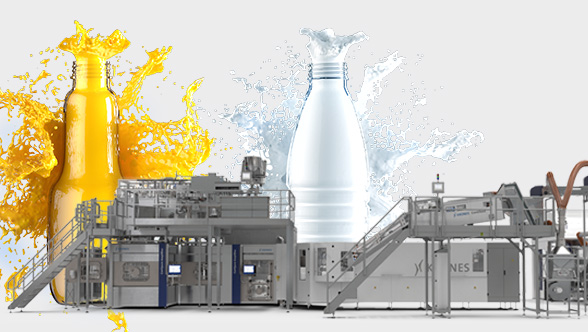

Coca-Cola HBC