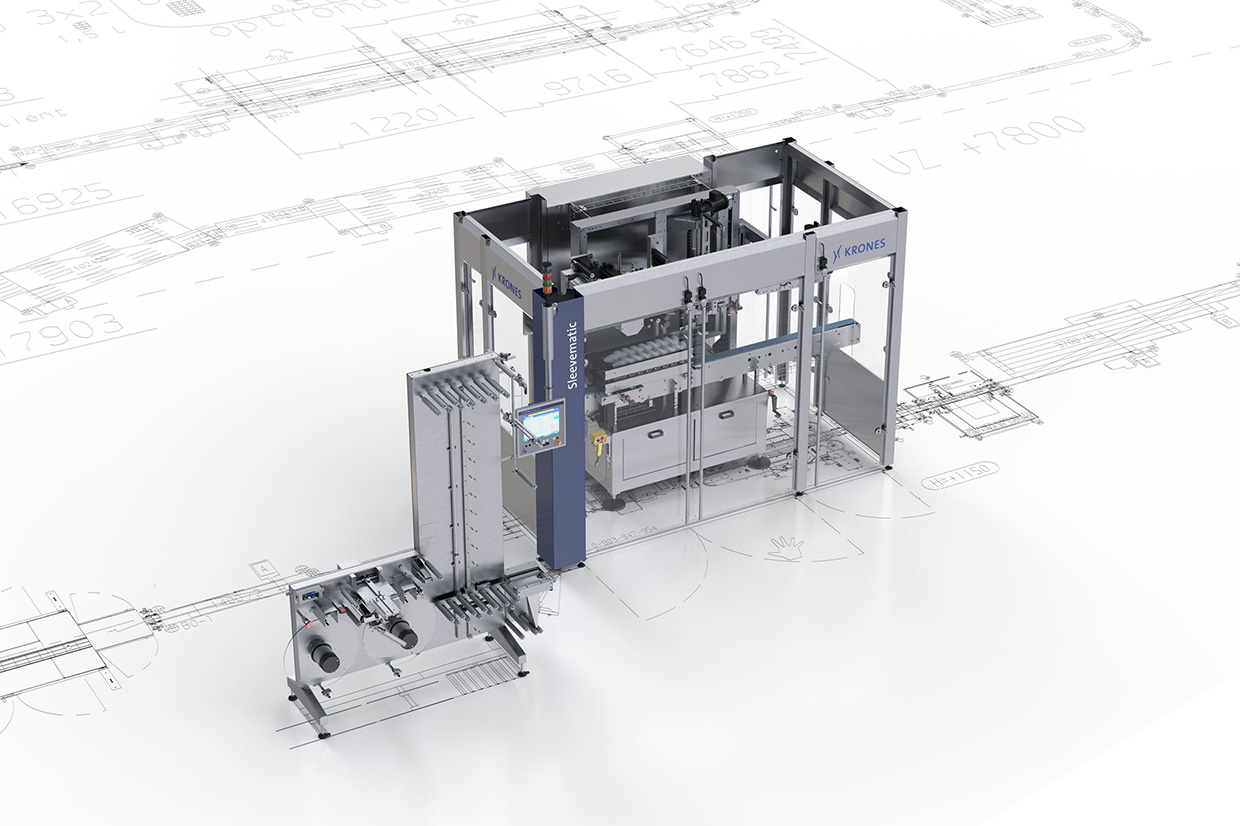

In order to maximise both machine availability and efficiency with the EcoFloat sleeves, the Sleevematic TS has been equipped with special add-on components suitable for processing polyolefin, like specifically adapted rollers and cutting tools. It took just one day to install them, with the machine then immediately reaching top speed and maximum efficiency.

The shrink-fit quality obtained with the EcoFloat sleeves is at a high level, similar to that achieved with standard PETG sleeve labels. So the Sleevematic TS is able to process polyolefin sleeves with only minimal adjustments to its design, making it a sound investment for the future which guarantees the highest possible level of sustainability.

To quote PepsiCo’s Ronny Liere from Manufacturing Operating Support: “At PepsiCo, we were thrilled to see the intensive collaboration between all parties involved and are delighted about the immediate success it brought to our existing Krones line. All we needed was a small add-on kit, with only minimal line downtime for its installation. Lipton Packaging R&D and our commercial team worked closely together to complete the test runs. We’re very satisfied with the result and see this project as an excellent example of the efforts undertaken by PepsiCo and the beverage industry in general to create a sustainable future, as represented by the two leading brands Krones and CCL.”

The support we got from PepsiCo and Krones was simply great! Everyone involved pulled together in order to advance sustainability, not least for sleeves.

Thorsten UmekProduct manager at CCL