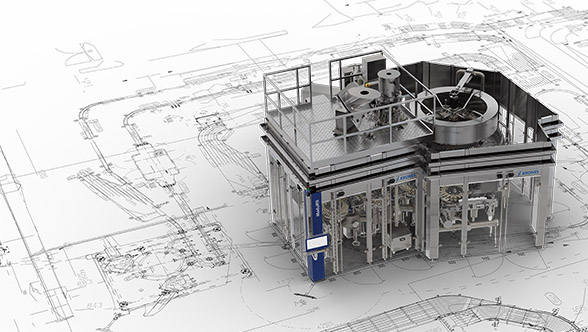

Rising inflation has affected not only consumers but also businesses over the past several months. Prices for raw materials and energy keep climbing higher, and production itself is becoming increasingly expensive. This has a direct impact on revenue, as higher costs cannot always be passed entirely to consumers – and ballooning food grocery bills may curtail beer consumption. In times like these, it is all the more important for companies to know their plants’ key performance indicators (KPIs) and to be able to compare them with industry benchmarks. It’s the only way to ensure that production costs are still moving within an optimal range.

Increasing price pressures make efficient production all the more important

But surging energy and raw material prices are not the only reason to take a closer look at your production and process flows. There are many instances when such a review makes a lot of sense, for example, if mechanical or electrical issues become increasingly frequent, if there are changes to work flows or personnel, or if inconsistent quality of raw materials results in lower yields. There are myriad reasons why it is worthwhile to carefully analyze existing equipment, and there will always be places where some fine tuning can result in increased efficiency and performance. And, with their wealth of experience, the Steinecker service team can provide valuable support here.