More than 90 percent of breweries rely on precoat filtration using kieselguhr (also known as diatomite or diatomaceous earth) as the filter aid. While kieselguhr offers many advantages, it also has its disadvantages, particularly with respect to disposal. It’s those disadvantages that prompted Krones to look for alternatives. And now we’ve added two clarification technologies to our portfolio: After five years under development, the Phoebus membrane filtration system has been available for sale since early 2020. In the same period, Krones has also been working on a precoat filtration system that uses an alternative filter aid. That system, too, is now ready for market.

At the heart of this process lies a compressible filter aid developed by Krones and now sold by KIC Krones under the name celcare.

The Krones celcare series comprises two products:

- For the initial precoating, 100 percent cellulose fibers are used.

- Then, in the second precoating and in the body feed, a combination of cellulose and perlite is used.

Both materials are combined in various amounts and at various degrees of fineness.

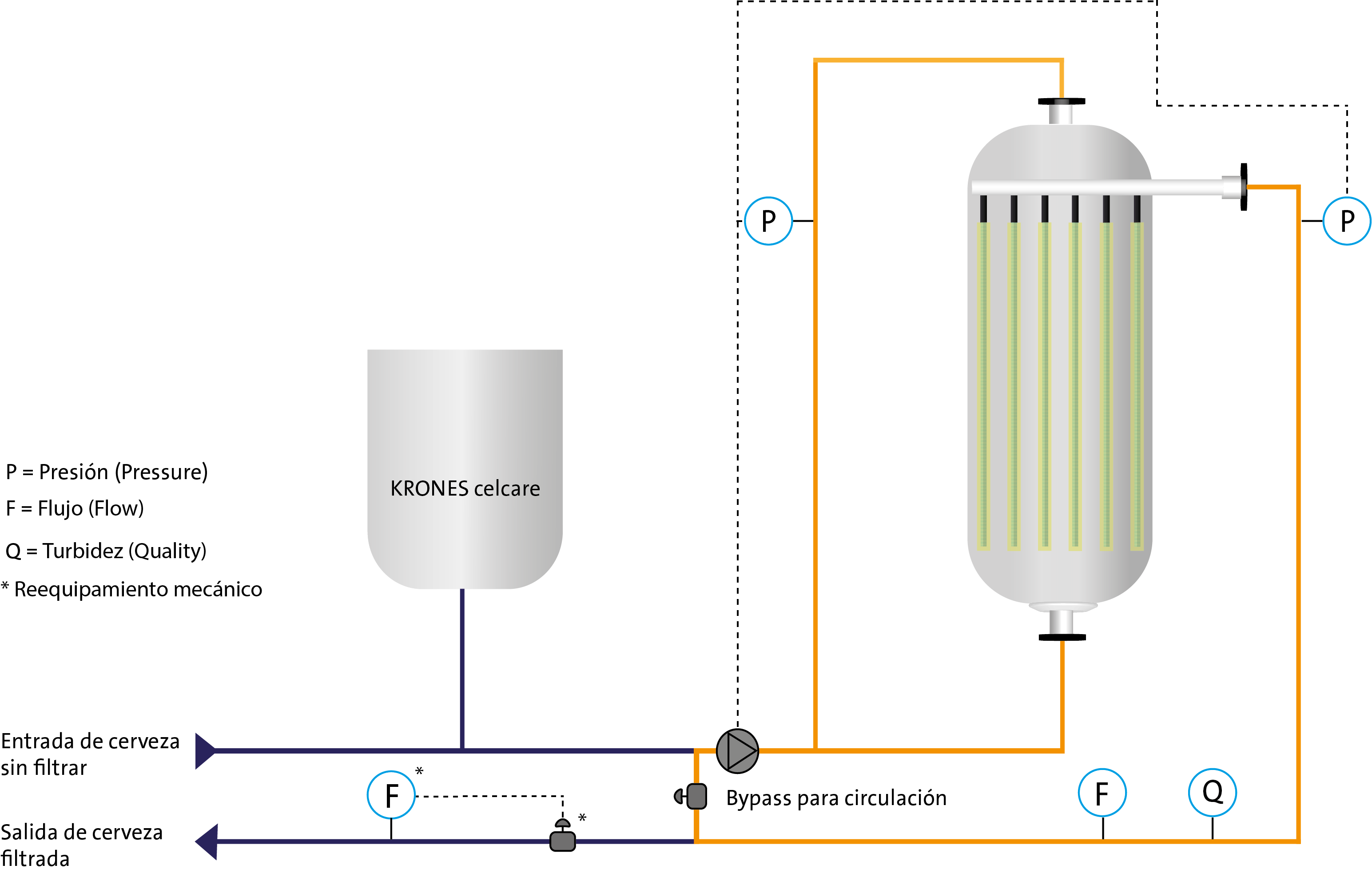

In order to achieve the desired degree of separation (and, ultimately, clarity or brightness), the filter cake has to be compressed in a controlled manner. And the process technology experts at Krones’ Steinecker plant have developed a way to accomplish that: A bypass is used to maintain the necessary differential pressure by circulating filtrate back into the unfiltrate feed (see graphic). During filtration, the dosage of celcare can be reduced considerably once the initial “precoating” stage (of rapidly building up the filter cake) is complete. In practical terms, that means the longer the filter has been in use, the less filter aid needs to be added.