Dr. Ralph Schneid is in charge of product development at Steinecker und has played a key role in devising the concept. In the text below, he is going to take you on a guided tour through the Phoenix BMC development project, which admittedly made a few detours and occasionally staggered to a halt. He is going to demonstrate why these swerves were perhaps even something like fate because now breweries can not “only” render their beer-brewing operations carbon neutral and energy-self-sufficient thanks to Phoenix BMC but also benefit from a side effect that turns out to be an additional, lucrative source of income:

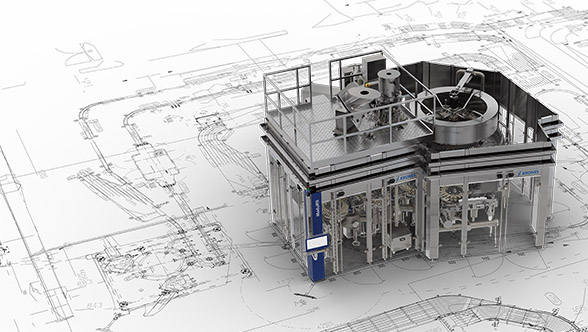

Brewnomic was premiered in 2017. Roughly four and a half years later, Steinecker has now finalised the concept of a carbon neutral, energy-self-sufficient brewery. One of its latest modules is Phoenix BMC – for upcycling residual materials from the brewing process and using them for energy recovery.

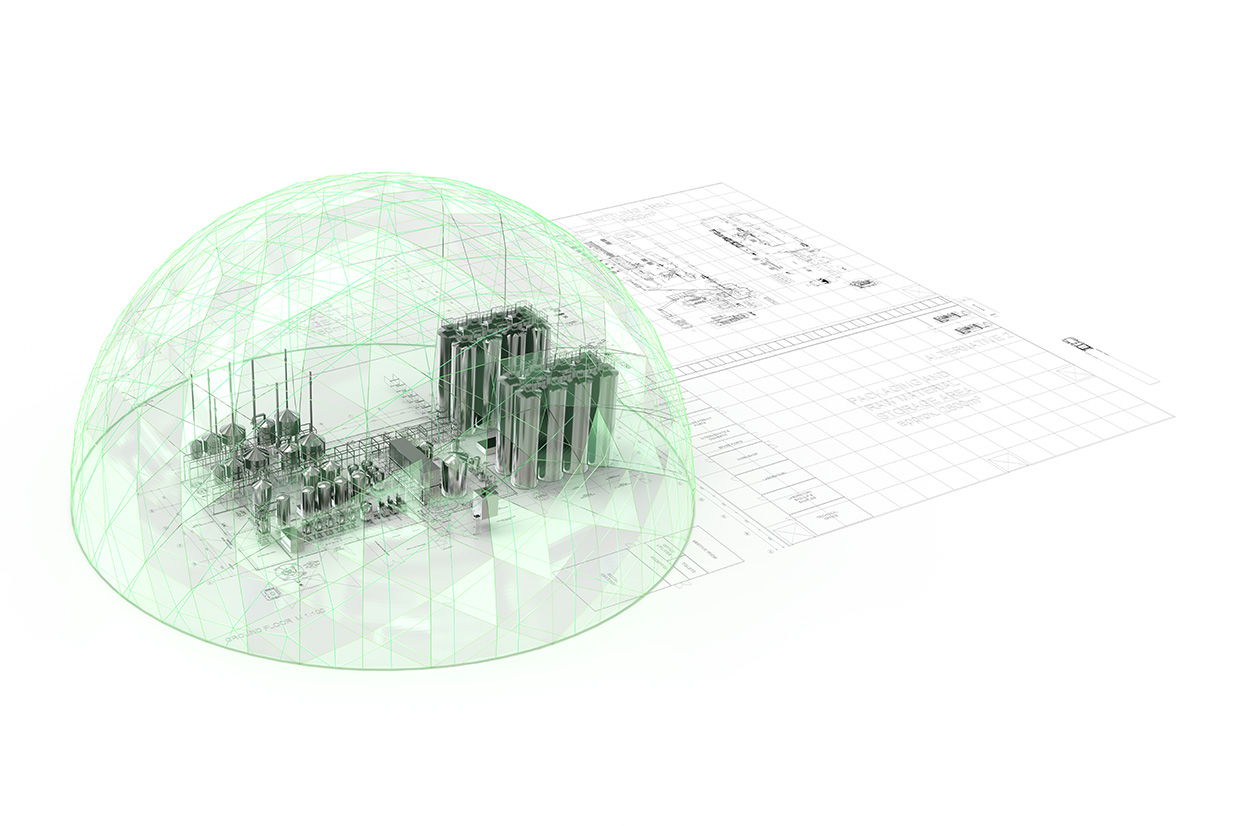

We have actually had a ready-for-use Brewnomic blueprint since the last drinktec. Its overriding goal is to operate a carbon neutral, energy-self-sufficient brewery. In order to achieve that, we exploit synergies that exist across systems. We reduce energy and media consumption by means of a wide range of innovative technologies in the brewhouse, in the cold section, in the filling line and in the supply-side peripherals. We use all the residual materials from the brewing process for energy recovery to optimum effect.

Phoenix BMC, and what it implies

Like the phoenix rising from the ashes, valuable substances contained in brewer’s grains, yeast and malt dust are given a new life by Steinecker. And once they have been extracted from the brewing residues, the remaining biomass is significantly easier to process in a biogas plant. That explains why the acronym BMC is part of the new module’s name: It stands for Biomass Conversion (BMC).

Integration of a biogas plant was part of the concept developed back then. But there was a snag – quite a substantial one at that. Even though it would theoretically be possible for such a plant to process the residual materials and use the biogas obtained to operate a combined heat and power (CHP) system, the biogas plant would have to be huge and therefore extremely expensive. In other words, it would not be commercially viable for any brewery. The plant’s dimensions would result not so much from the vast quantities of residual materials and/or their poor recyclability – as one would be inclined to think – but above all from the inhibitors they contain. These inhibitors prevent the methane-producing bacteria from doing their work. And once the bacteria’s strength has been impaired, the biogas plant’s efficiency is substantially reduced. So in order to make up for the bacteria’s slower work and provide the requisite performance all the same, the plant would have to be quite large.

The alternative to a biogas plant we suggested at the time for still ensuring a sustainable energy supply in our Brewnomic concept was that the brewery run the CHP system with municipal gas. This provides the same energetic advantages and reduces the brewery’s carbon footprint by around 60 per cent.

Where to now, breweries? Towards 100 per cent energy self-sufficiency

Green power, sure – but generated in-house, please!

However, when the inquiries for Brewnomic started rolling in, we noticed that most of the prospective customers did not want to “just buy” green power from the municipal provider but actually wanted to generate it themselves. This is because green power is a valuable commodity and should be used by those branches of industry that do not themselves have an option for in-house production. Breweries interested in the Brewnomic, by contrast, are very keen to be energy-self-sufficient – for both marketing- and cost-related reasons.

Proteins in the spent grains: both inhibitor and treasure

But it was not only the market itself that prompted us to rethink our original biogas plant concept. The Circular Economy Action Plan adopted by the EU in 2020 laid down that as from then on nutrient-rich residual materials were no longer to be used for energy recovery in the EU.

Although it was not until 2020 that the plan was officially adopted, the concept had been around for some time before that. Therefore, we realised quite early on that our initial idea of recovering residual materials exclusively in a biogas plant would presumably not remain a viable option in the long term. This is because spent grains and yeast consist largely of proteins – in other words, of nutrients.

So it was clear that if our idea of an energy-self-sufficient Brewnomic brewery was to have a future, we had to come up with a Plan B. And we soon found one. Lucky for us, we got in touch with two development specialists for biomass conversion back in 2018: Prof. Waldemar Reule and Dr. Rainer Gottschalk had already devised a three-stage approach and had it patented. In the first stage, the nutritive substances are extracted from the brewing residues, after which the inhibitors are separated. In the downstream biogas plant, only the materials then left over are converted into energy.

That kills two birds with one stone: Firstly, the plant does not have to be nearly as big as we originally thought for the same output. And secondly, this process also complies with the stipulations of the EU’s Circular Economy Action Plan.