Not only does filtration determine a beer’s visual appeal, it also extends its shelf life by improving its chemical and physical stability. So filtration is a vital step in the beer-making process, for which various technological options are available: The top dog among filter aids has always been kieselguhr but the material has increasingly been coming under scrutiny. “Firstly it’s getting ever more difficult to dispose of it. Kieselguhr used to serve as fertiliser in agriculture but that has actually been prohibited in the EU since 2014. So breweries would now have to pay for the disposal of their spent kieselguhr,” explains Matthias Pohl from Steinecker Sales, adding: “What’s more, the International Agency for Research on Cancer back in 1997 classified crystalline kieselguhr as carcinogenic, meaning it’s a health hazard for any brewer coming into direct contact with it without taking protective measures.”

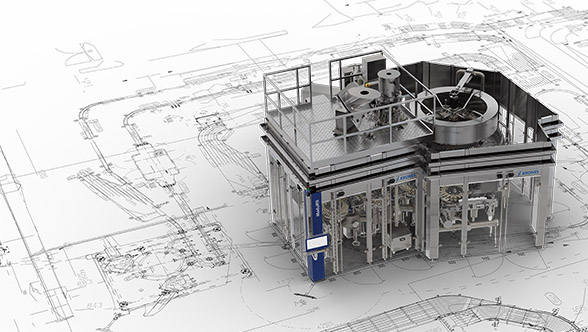

All of that makes one thing abundantly clear: We have to find alternatives. The Erbslöh GmbH company is headquartered in the Hessian town of Geisenheim, and its portfolio already includes suitable substitutes, such as the VarioFluxx series that works on the basis of perlites and cellulose fibres. In late November 2023, a cooperation agreement with Krones’ subsidiary Steinecker was concluded at the BrauBeviale because the VarioFluxx technology is a perfect match for Steinecker’s Twin Flow precoat filtration system.