Extremely low energy and consumption figures

Syskron is not the only subsidiary involved in the new line. On the old line, the Murau brewery was already using adhesives and cleaning agents from KIC Krones. Since now, of course, the conveyors were included in the delivery package, the brewery is also deploying the lubricants from the consumables specialist. This means it’s the first plant in Austria to be using three out of the five product categories in KIC Krones' portfolio. “That was very important to me personally,” explains the Managing Director. “Thanks to the efficacious interaction of machinery and chemicals, we have managed to achieve a massive reduction in expendables consumption – which in its turn, of course, fits in perfectly with our corporate strategy.”

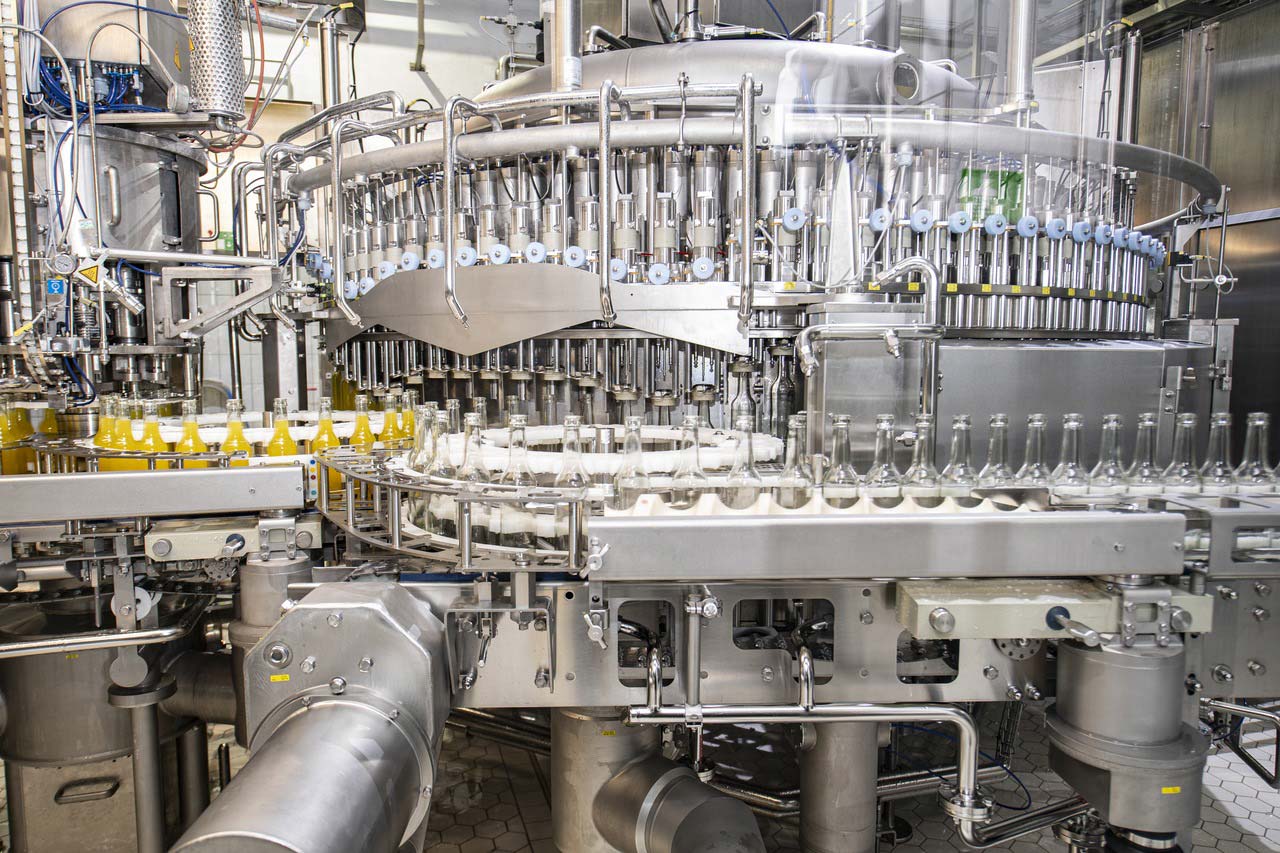

After all, the issue of sustainability plays a key role in all of the Murau brewery’s investments. With the new line too, for instance, it was a key stipulation that energy and water consumption had to be minimised, as Josef Rieberer relates: “As far as the water savings are concerned, the line achieves superlative figures: the biggest quantifiable and meaningful figure is the water consumption per hectolitre produced. This used to be 6, but now with the new machines it’s a mere 4.33 hectolitres. That is a sensational figure, one that we had not expected after only five months.” As with the brewhouse, Murau gets the energy from the biomass cogeneration plant. Here, too, for example, the heat exchanger rating has already been substantially downsized.

It’s the people that make the difference

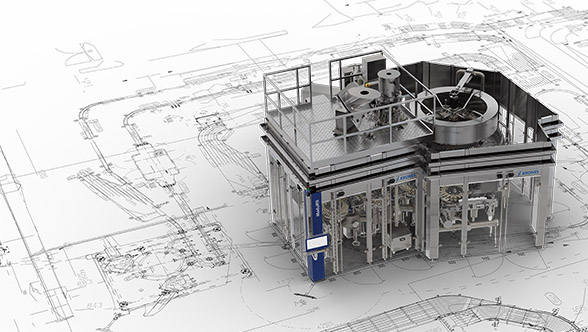

The decision to opt for a single-sourced line paid off in the project’s hot phase at the latest: “Since Krones functioned as a complete-package vendor, we were able to minimise the number of interfaces. This was certainly one of the reasons, too, why we could keep the installation phase extremely short,” to quote Josef Rieberer.