Remaining flexible during packing and unpacking

Keeping a firm grip on container diversity

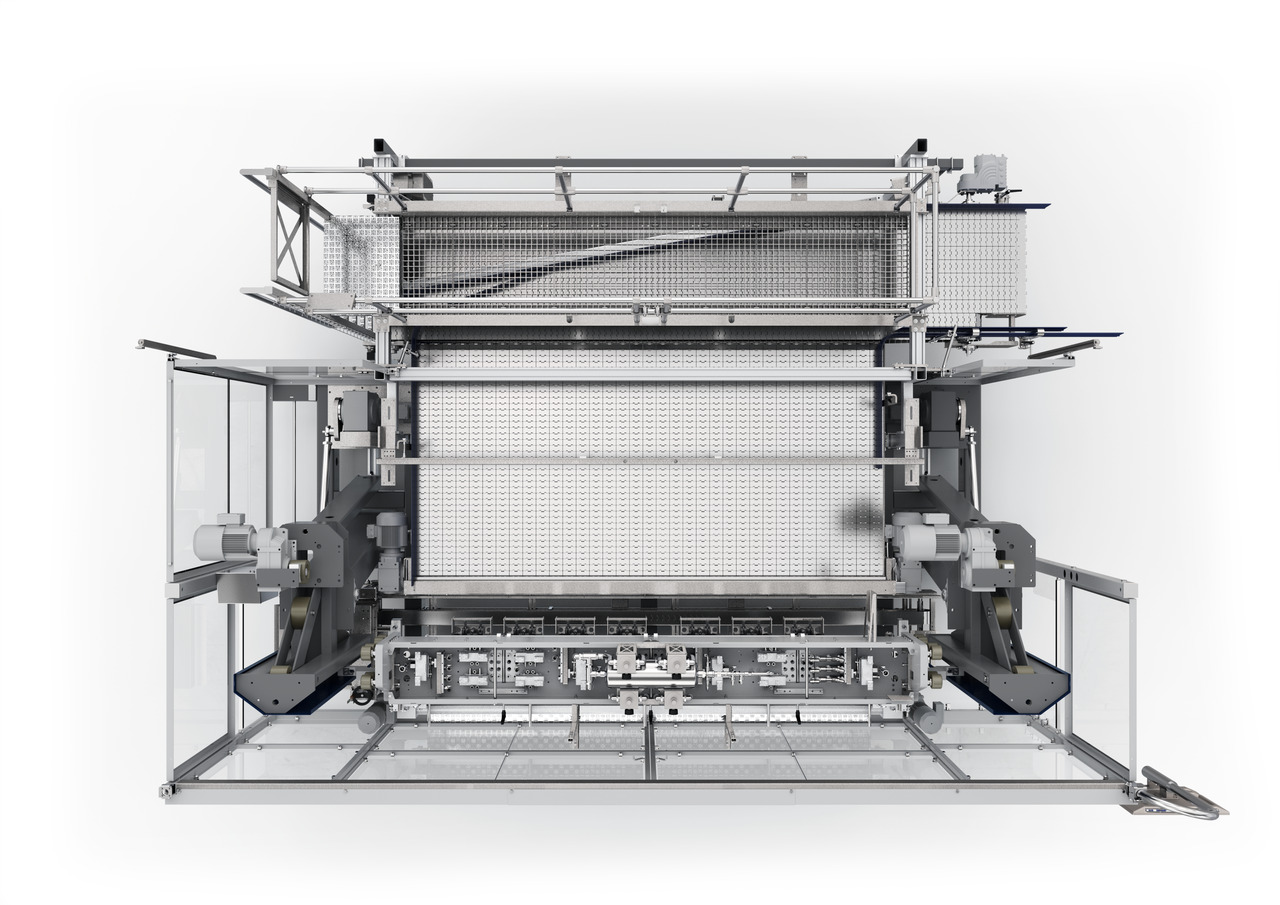

Nowadays, it is normal to have a wide variety of containers and packs. It is the job of the Smartpac to process different container formats in secondary packaging. With its modular design and large range of gripper heads, this intermittent packer is prepared for a wide spectrum of variants. Precisely tuned movement sequences ensure the gentle treatment of your products. With the Smartpac, your containers are in the best of hands.

At a glance

- Secondary packer for cylindrical or specially-shaped glass or plastic containers

- Use for packing and unpacking crates, trays and cartons

- Pack block lengths ranging from 1,420 to 2,975 millimetres possible

Method of operation

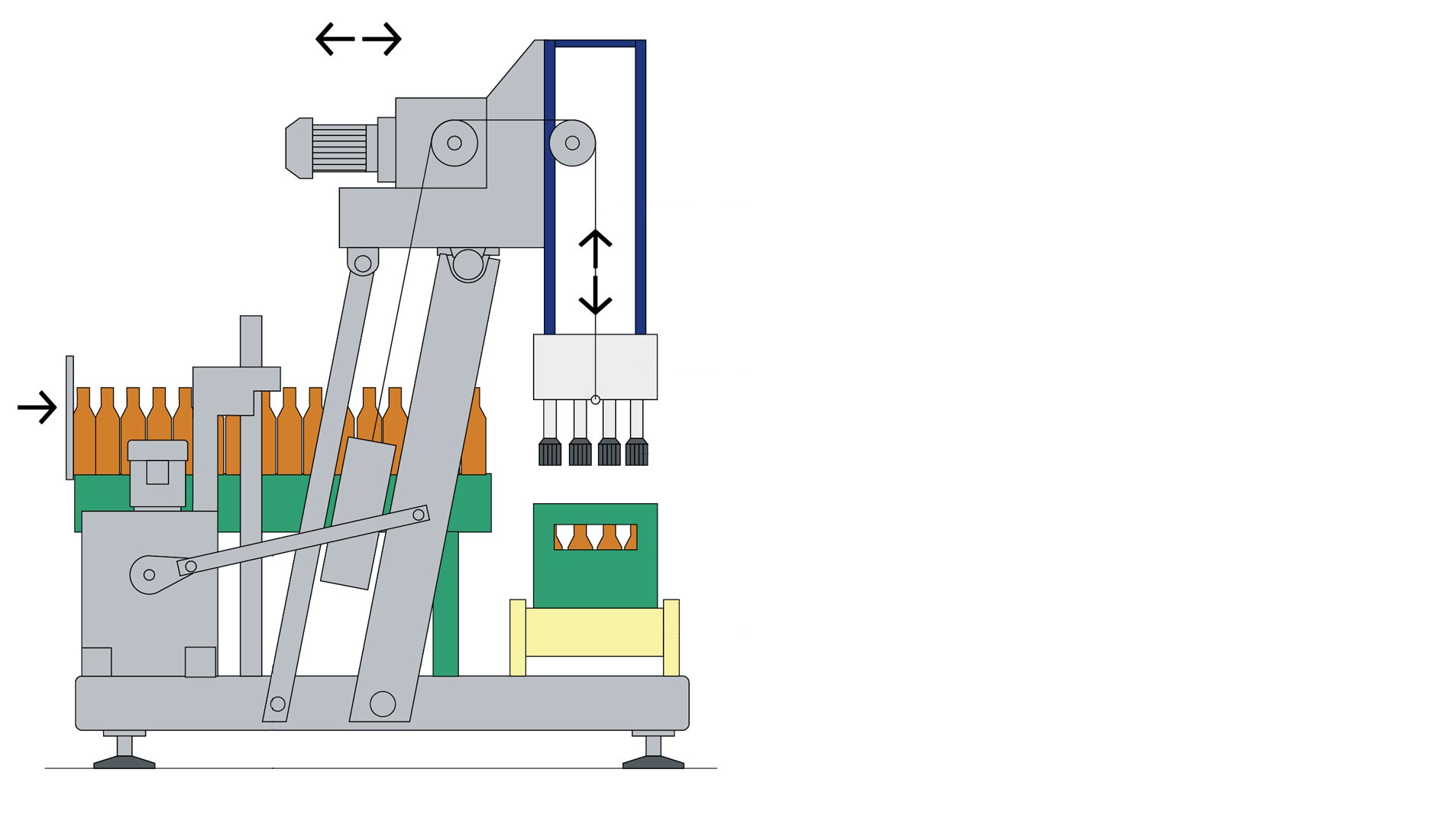

Packing

- The bottles on the container table are divided up onto lanes

- The pre-positioned containers are picked up using gripper heads and set into the fed packs

- The bottle formation is set down reliably with the integrated insertion frame

Unpacking

- The fed packs are stopped at the removal position

- The gripper head is lowered and the containers picked up and removed from the packs

- The containers are set down onto the container table

Packing curve

- Combined from the horizontal and vertical movement of the lifting unit

- Different programming of the trajectories for loaded and empty gripper heads

- Horizontal movement: pivoting column with crank drive for gentle approaching and braking characteristics

- Vertical movement: lifting unit with frequency-controlled motors

Technical details

Design features

- Container table with stainless steel flat-top chains or plastic flush-grid belts

- Stainless steel pack conveyor with infeed and pack stopper

- Single-lane or double-lane conveyor

- Gripper heads and layer systems with quick-change function

- Lifting unit with maintenance-free toothed belt drive

- Integrated safety stop feature

- Pneumatic or motorised drive for the insertion frame

- Oscillating mechanism supports – depending on the machine size

- Control cabinet integrated directly on the machine

- Machine guards with sliding or double-wing doors

- Structure comprising:

- One oscillating mechanism support for machines in the low to medium output range (size: 1400)

- Two oscillating mechanism supports for machines in the medium to high output range (size: 1800 to 2900)

Benefits to you

Sturdy and reliable

The Smartpac can withstand tough treatment: its sturdy construction comprising standardised elements keeps the amount of wear and maintenance to be performed at a low level.

Flexible application

The extremely diverse variants offer high flexibility when it comes to the gripping devices, meaning that the Smartpac can handle a large number of different container and pack types.

Quick conversion

The Smartpac is soon ready for action again after a product change-over. With its short change-over times and brief periods of inactivity, the packer is distinguished by its high productivity.

Compact and easily accessible

The logical, easily understandable machine construction allows the operator to continually operate the Smartpac at a high output.

Clear operation

Production data, operating functions, status indicators, help texts and diagnostics tools in the respective native language make it possible to operate the equipment quickly and comfortably on the touch-screen.