Great fans of a block configuration

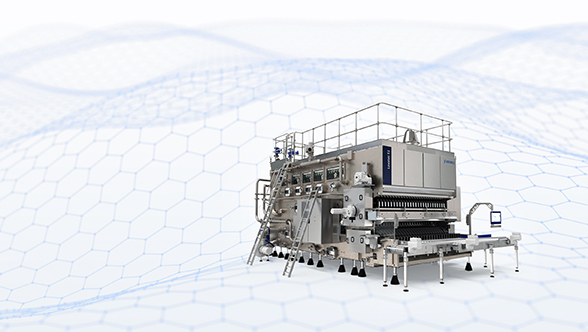

“What we particularly liked about the solution offered by Krones was the block concept,” says Martin Abfalter, the owner and Managing Director. “The direct link between labeller and filler, especially, was instrumental in doubling the line’s output compared to the previous speed, and that on a very small floor area of just 600 square metres.” Furthermore, the human engineering in the new line is better, and the line is more efficient while also meeting the latest hygiene-related requirements. “We opted for a somewhat bigger filler, with a pitch circle diameter of 2,880 millimetres and 88 filling valves. This makes for slower (and thus smoother) running, a fact that directly benefits the filling quality,” explains Frank Mösel. For this investment, St. Leonhards also made rigorous use of the latest valve and pump technology from Evoguard because this, thanks to its high quality and its design precisely matched to the process conditions involved, is predestined for assuring gentle water treatment.

What we particularly liked about the solution offered by Krones was the block concept.

Martin AbfalterOwner and Managing Director

Martin AbfalterOwner and Managing Director