Best-precision mixing and carbonation

Mixers and carbonators for the production of different beverage types

Non-alcoholic refreshment drinks are on the road to success. As a result, more and more flavour combinations are appearing on the market and arousing consumer curiosity. A flexible line technology which provides a maximum leeway for the beverage manufacturers is required.

At a glance

- Mixers and carbonators for the production of different beverage types

- Comprising three modules: deaeration, dosing and carbonation

- Up to six different sizes with variable outputs (33 to 100 percent) of 15, 30, 45, 60, 75 and 90 m³/h are available.

- Highly accurate dosing of syrup and CO2 for a lower syrup consumption of up to 0.2 percent

- Optional: integration in the Modulfill VFS-M through the elimination of the interface between the filler and the mixer

Modules in detail

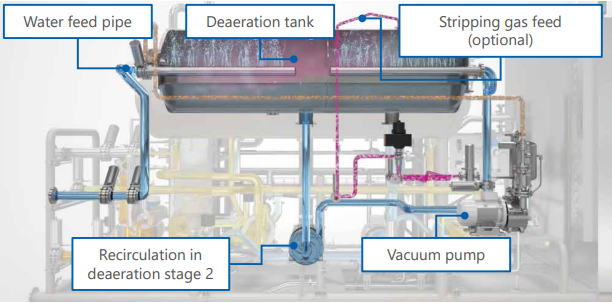

Deaeration

- Water feed to the horizontal deaeration tank via two sets of nozzles of different sizes

- Deaeration using a single-stage or double-stage vacuum process and optional support with stripping gas

Benefits to you:

- The stripping gas (CO2) provides: accelerated removal of the gasses from the water which ensures efficient deaeration

- Reduction of the sealing water consumption to a minimum thanks to a water saving function in the vacuum pump

Overview of the types of deaeration

−Single-stage = residual oxygen content: ≦1.5 ppm*

−Two-stage = residual oxygen content: ≦0.8 ppm*

−Two-stage + stripping gas = residual oxygen content: ≦0.5 ppm*

* At 15 °C and with an initial oxygen content of 10 ppm

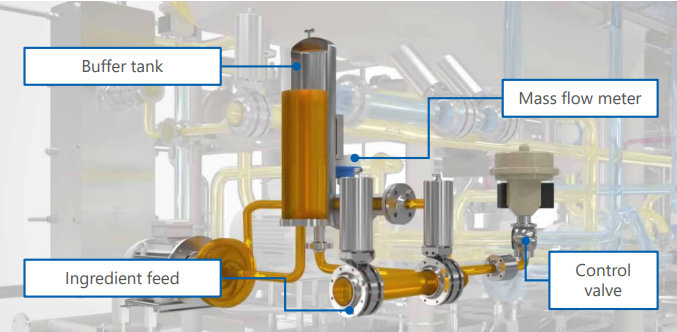

Dosing

- Buffer tank for removing the gas bubbles from the ingredient

- Efficient register controller: precision control of the syrup dosing process, thus achieving potentially high raw material savings

- Recording of the ingredient volume flow rate with a mass flow meter

- Dosing of up to eight liquid ingredients possible

Benefits to you:

- Precision control of syrup dosing: for a high potential raw material savings

- Top product quality due to multi-stage product homogenisation

Mixing water and ingredient in the correct mixing ratio:

Brix accuracy:

−In all circumstances: ≦ 0.03 °Bx*

−If the production conditions remain consistent: ≦ 0.01 °Bx*

* Described as sigma 1, based on a target brix content of 10 °Bx

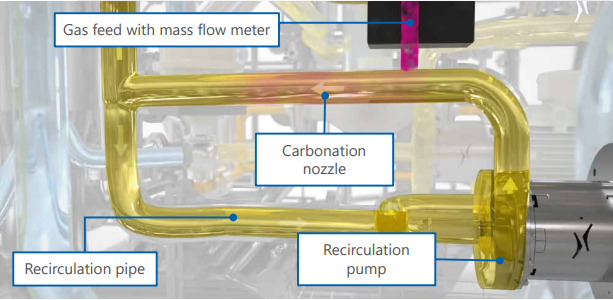

Carbonation

- The carbonation nozzle ...

- Always operates at a consistent volume flow rate

- Guarantees efficient and consistent carbonation (independent from the machine output; between 100 and 33 percent)

- Dosing of up to two gaseous ingredients possible

Benefits to you:

The incorporated CO2 must be dissolved completely before the filling procedure can be faultless. This is guaranteed through the combination of high-pressure carbonation (> 8 bar) in the Contiflow and gentle product transfer to the filler.

Krones procedure for high-pressure carbonation: > 8 bar

CO2 dosing accuracy:

−In all circumstances: ≦ 0.08 g/l*

−If the production conditions remain consistent: ≦ 0.04 g/l*

* Described as sigma 1

The product tank integrated in the Contiflow ...

- decouples the deaeration, mixing and carbonation processes from the filler,

- balances out production fluctuations,

- ensures that the filler is evenly and consistently supplied with product – and this at a continuous production output.

In detail:

- Adjustment of the production output in the Contiflow: between 100 and 33 percent of the nominal output

- For a consistent product quality: multi-stage product homogenization during production

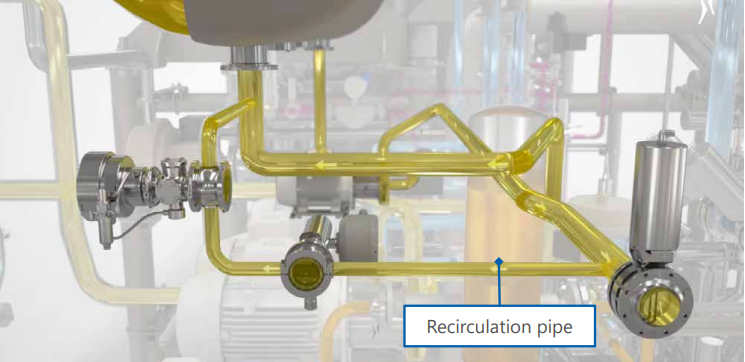

- Recirculation carbonation: about 25 percent of the product circulates through a short bypass pipe within the CO2 dosing pipe (loop).

- During the inflow into the carbonation tank: approximately 6 percent of the entire product volume permanently recirculates at the carbonation tank discharge.

Process monitoring in the recirculation line:

Brix, CO2 and alcohol values of the finished mixed drink are measured inline.

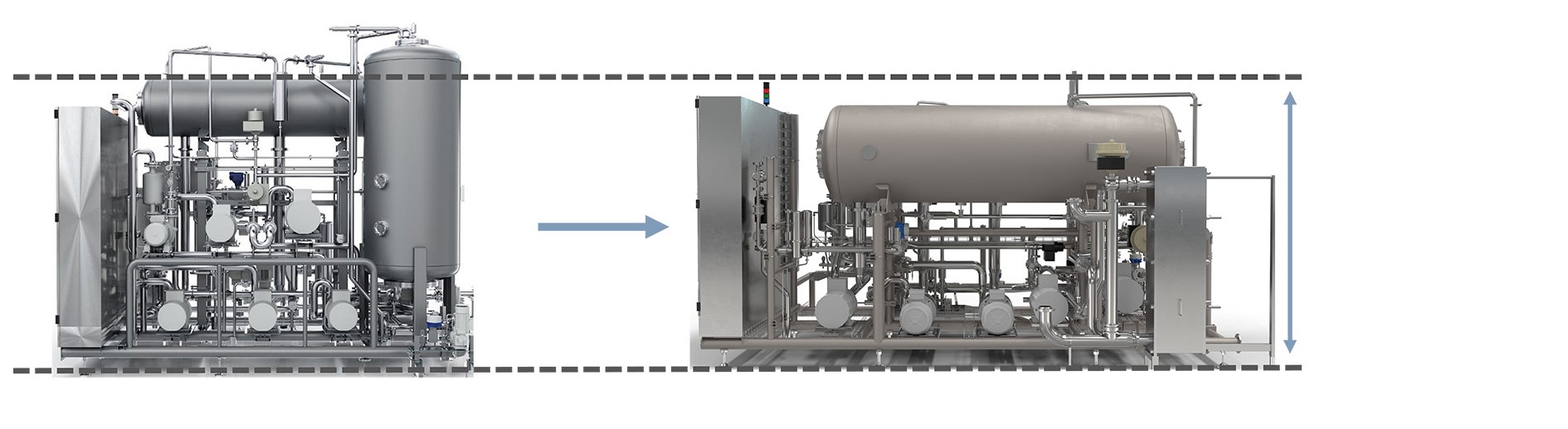

If required: available in the new machine design

Following the sale of more than 1,500 systems (as of: 2022) all over the world, Krones has now optimised the Contiflow. The new design stands out because of its numerous benefits:

An open and easily accessible mixing station design thanks to the stainless steel circular tube frame

A drainage pan is mounted on the base frame to combine all of the waste water and drain it off from a central position

Easy-to-maintain design: e.g. pumps are mounted on a moveable slide so that the mechanical seals can be replaced quickly; all pumps are installed close to the ground

Reduced construction height: container dispatch possible

Integrated mixer as part of the Modulfill VFS-M

Quicker and more compact than ever: in the Modulfill VFS-M, the Contiflow mixer is connected directly to the filler. This way, the product is transported to the distributor via the carbonation tank installed at a raised position. The traditional filler bowl is therefore no longer necessary.

- Reduced media consumption thanks to short mixing phases (no ring bowl, shorter pipe distances between the mixer and the filler, optimised pipe routing inside the mixer)

- Reduced CO2 consumption thanks to small head space (no the ring bowl)

- Loss-reduced filling at the end of production thanks to raised position of the buffer tank

- Reduced power consumption by use of gravity (product discharge pump with 11 kW replaced by a recirculation pump with 1.1 kW)

Advantages of the integrated mixer

Faster filling speeds

The direct connection between the Modulfill VFS-M and the Contiflow mixer positively affects the filling duration. The integration in conjunction with the raised tank enables up to 250 millilitres to be filled per second.

Accelerated change-over

You will be well equipped for type and handling parts change-over: the optimised interface between filler and mixer and the integration of LineXpress minimise the product change-over to less than ten minutes.

Ease of operation, reduced space requirement

As the mixer and the filler are directly connected to each other, they can share a central HMI. In addition, the valve manifold was reduced and integrated in the mixer. The complete process control sensor system is installed inline.

| Your benefits in figures | Savings*/duration |

|---|---|

| Less loss during emptying and change-over | Up to 30 percent |

| Fast change-over times during product change-overs with LineXpress | < 10 minutes |

| Space saving thanks to a compact design and optimised interfaces | 10 to 15 percent |

| More compact filler clean room design possible as the product tank is installed on the mixer | 600 millimetres in height |

| Lower amount of cleaning agent required for CIP | Up to 15 percent |

| Savings in operating costs | Up to 10 percent |

* Compared to line arrangement with separate filler and mixer

Benefits to you

Economical use of syrup

The syrup consumption can be reduced drastically thanks to the production at the bottom limit of the Brix range. In addition to that, a Brix-value-controlled admission of the syrup prevents the loss of syrup dosing the start and the end of production as well as during a product change-over.

Flexible output

The mixer production output can be individually adjusted from 33 to 100 percent of the rated output. The regulated output results in a reduced gas consumption.

Low operating costs

The demand of process water is reduced to a minimum by admitting the sealing water at a later point depending on the temperature.

Automated processes

The rinsing function via water or syrup supply starts automatically already during the production. The operators are relieved and can focus on other tasks.

This is why the Contiflow is enviro-classified

Energy efficiency

- Use of the latest and optimally designed drives and pumps

Media efficiency

- Minimum water consumption of the vacuum pump due to recirculation and cooling of sealing water using product water

- Less CO2 losses thanks to saving mode

- Syrup loss is prevented by Brix-controlled syrup feeding (optional)

- High-precision dosing: Reduces the use of expensive raw materials