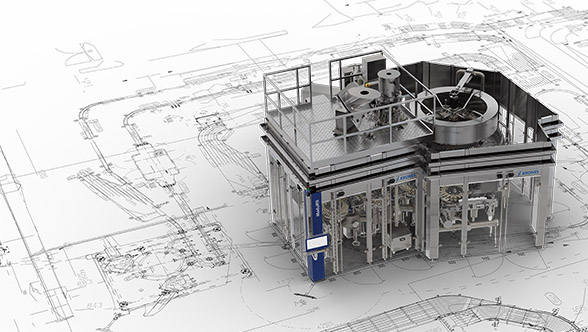

Whether it’s the brewing of beer, bottling of juices, treatment of products in a tunnel pasteurizer, or flash pasteurization – efficient cooling makes it possible to quickly continue with the product’s further processing and also ensures high quality and impeccable flavor. With the specially designed VapoChill cooling tower, Krones has demonstrated a knack for cooling and for meeting the critical needs of the market.

VapoChill is built on a modular principle. Depending on the configuration, the individual models can later be easily expanded and/or combined. The design is based on Krones’ tunnel pasteurizers, which have performed successfully on the market for ten years now. The housing of the VapoChill is made completely of high-quality stainless steel, which means that the system is built to last. It is also available in the more chemically resistant V4A or AISI 316L stainless steel, on request. The tower packings, which are made of polypropylene, can optionally be treated with a biocide.

A significant advantage of the Krones VapoChill is its exceptionally clean design, which includes sloped surfaces that allow water to run off, the elimination of dead ends in the pipework, and a low volume of water inside the cooling tower. As a result, thorough cleaning can be accomplished with minimal personnel effort and time.

The cooling tower also offers excellent accessibility thanks to removable sidewalls and tower packings. Double detachable sieves make it possible to examine and clean parts of the system while it is in operation. Krones also offers dosing stations for water treatment chemicals as an optional extra. The chemicals themselves are sold by KIC Krones.