DrinkPAK was founded in Santa Clarita, California by three industry veterans during the COVID-19 pandemic. Focusing on the lack of innovation they saw in the contract manufacturing space they used their own experience as customers to help build an ideal co-packing provider. “When we were customers of contract manufacturers, we were perpetually frustrated that the capabilities weren't there, the capacity wasn't there, the flexibility wasn't there,” says Nate Patena, CEO. “So, we decided it was time for somebody to put their money where their mouth was to invest in really high-tech aluminum can contract manufacturing in the United States… and to do it in a meaningful way with big volume, big capacity, and big commitment to flexibility in different can sizes and different pack formats.”

Speed, intensity, and purpose. Referred to as “SIP,” these concepts have been at the core of DrinkPAK’s values since the beverage co-packing company’s founding in 2020. DrinkPAK's state-of-the-art facilities have been built around extreme capacity and flexibility. “Our vision is any liquid, in any size can with any pack configuration” says Gary Corona, General Manager.

Although it was a risky time to start a new business venture due to the global pandemic, the three partners saw opportunity. As the business landscape began to change, the DrinkPAK team found there was a huge untapped demand in the marketplace for RTD’s of all kinds. Corona recalls, “It was an opportune time for us to really go the opposite direction from where everyone else was going at the time, allowing us to obtain the right buildings needed to support this operation… and to secure the right equipment from Krones.”

Partners From the Start

Having already built successful relationships with Krones from their previous brand-building ventures, DrinkPAK’s ownership was interested in a partnership from the very start. “Krones was basically selected before we had the initial conversation,” Patena says. “We needed to know at the end of the day that these projects are going to get done. They're going to exceed our expectation and they're going to give us the playground to be able to make the best products in the world.”

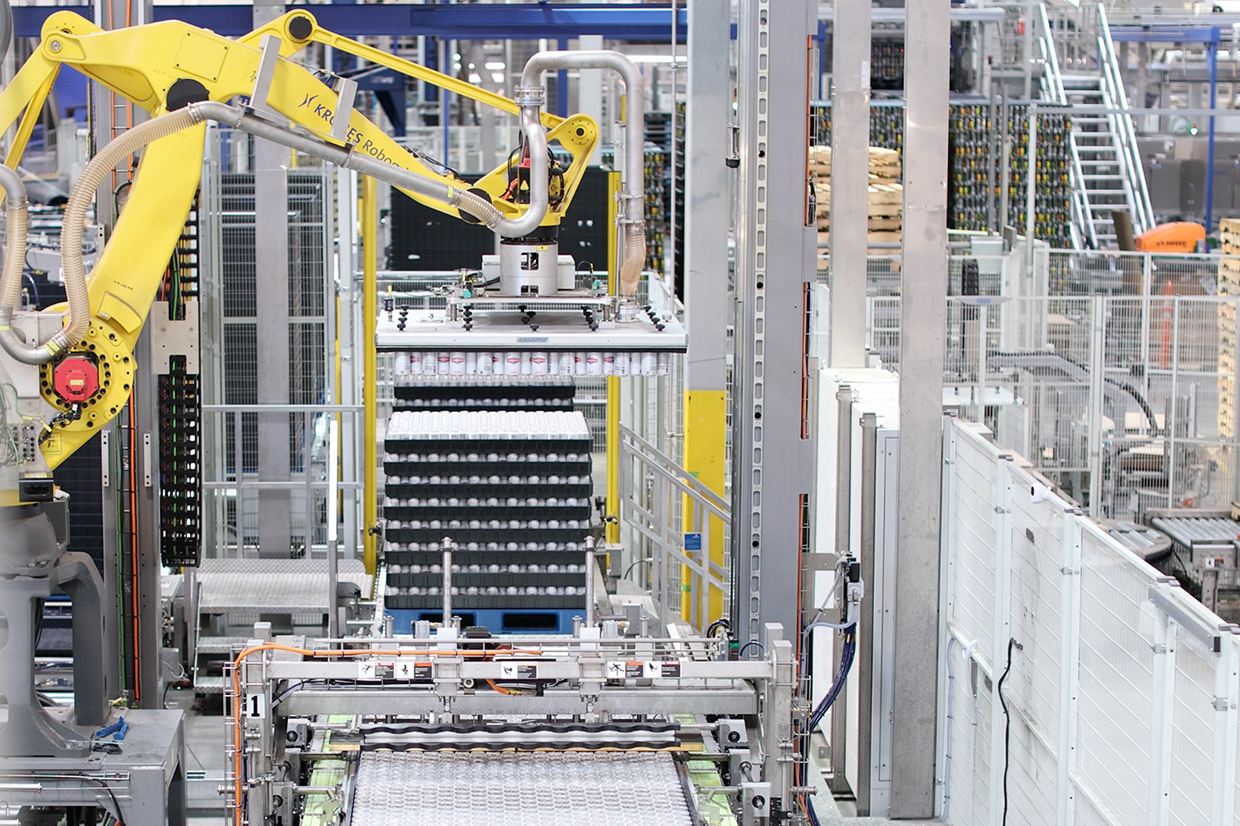

DrinkPAK’s first Krones turnkey canning line with a pasteurizer was commissioned in 2021, hitting production speeds of 57,000 cph. At that time, there was still a bit of uncertainty as to what the future looked like for the newly founded co-packer, but with the company experiencing almost immediate success, they quickly planned for an additional Krones high-speed canning line that more than doubled their production capacity at 108,000 cans-per-hour. Since that time their massive growth continued and a third Krones line with speeds up to 120,000 cph was commissioned, as well as a fully automated variety pack line allowing DrinkPAK to package multiple flavors and SKUs in a common pack. But with that rapid growth came unexpected challenges.

“What this facility has become after three and a half years is a lot different than what we had originally conceived… in all the right ways,” says Patena. “It's bigger, it's faster, it puts out more product, and it's more flexible.” The DrinkPAK facility in Santa Clarita, CA was not originally envisioned to house three high-speed, high-output lines. In fact, each subsequent line installation after the first had less space in which to work. Seeing this as both a challenge and an opportunity, Krones and DrinkPAK worked together to establish some creative solutions to meet the growing production needs, such as including overhead mezzanines, compact machine design, and over-under conveyors. “Candidly, it's been one of the most surprising wins over the last few years,” he adds. “The fact that we’ve put some very large lines into very tight spaces and have had them functionally turn out excellent and beautifully.”

Individualized Training – Specialized Support

An additional challenge that has come with the massive growth has been the need to hire and train more skilled production workers. Familiar with Krones’ Training Academy, DrinkPAK partnered with Krones to build out learning and development programs, including on-site training allowing production floor trainees to assist Krones Technicians during commissioning. And the feedback loop has continued as Krones continues to evolve their training based on user input. “One of the big things that Krones does differently than their competitors are they make it very learner-centric in terms of the content for the training curriculum,” says Jim Utley, Executive Vice President of Operations. “They want to hear the feedback from the operators who actually run the machines to know what the frequent headaches are, the gaps in their knowledge, and they tailor the content of their Krones Academy offerings to what's actually needed in the field by the customer.”

Opportunity, Expansion, and the Next Chapter

DrinkPAK is has its sights set on continued growth and expansion, with plans to build additional facilities across the US. They maintain that their “SIP” values are not only the foundation for why they’ve been successful, but the basis for future success as well. Utley believes the primary difference is that they embrace a level of technology through Krones that many other competitors don’t choose to do. “We run much faster lines. We offer the ability to produce any beverage into any size can with any carton format and any case pack format, any pallet sizing format. And we'll do those changeovers 24 hours a day, seven days a week. A lot of the other players in the market space won’t offer that flexibility and they certainly won’t offer that kind of responsiveness.”

Patena adds that having a valuable partner like Krones will help ensure success into the future. “The relationship with Krones is about the healthiest familial relationship that we have on the vendor side,” says Patena. “I think that as you look at it, Krones is very much the best in the world at what they do.”

About the project

| Project: | Three turnkey canning lines and one partial line |

| Customer: | DrinkPAK |

| Location: | Santa Clarita, California |

| Orders: | Multiple turnkey can lines with varying speeds: |

| 2020: | Line #1 – Can line (57,000 cph) |

| 2021: | Line #2 – High-speed can line (108,000 cph) |

| 2022: | Line #3 – High-speed can line (120,000 cph) |

| Line #4 – Variety pack packaging line with Variopac Pro |