Annual per-capita consumption of beer in Colombia comes to more than 50 litres, ranking the country third in all of Latin America – and the uptrend continues! Logically enough, the new brewery in the vicinity of the seaport of Barranquilla is Bavaria’s long-term investment in the sector’s significant growth. Likewise specified for the long haul, the stringent sustainability standards for the brewery in the making are designed to help meet AB InBev’s sustainability targets for 2025, with net zero carbon emissions and the intention to brew all products with solar energy.

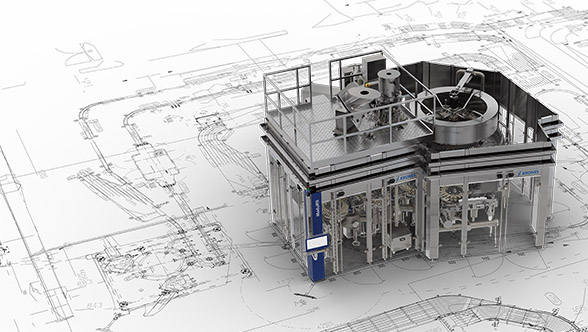

Bavaria & CIA S.C.A. is Colombia’s biggest brewery and with its national beer brands like Águila, Poker and Club Colombia ranks among the Colombians’ five most popular companies. By erecting an additional brewery in Palmar de Varela, a district in the country’s north, Bavaria shows that it wants to continue investing in its over-130-year-old business here. The brewery has ordered no less than three new lines from Krones for this project.

Relationship of mutual trust

Krones and Bavaria can look back on a long line of projects completed together. The facility in Barranquilla also operates some Krones machinery, including a canning line and a PET line. So when in response to the high market demand the beverage producer decided to invest in a new greenfield brewery meeting stringent sustainability criteria in the vicinity of Barranquilla, it was only logical that the company should rely on Krones solutions for its filling and packaging kit here as well. In the end, Bavaria opted for a 120,000-cph canning line and two returnable-glass lines, rated at 72,000 bph and 66,000 bph respectively.

To fit in with Bavaria’s sustainability standards, appropriate energy-saving modules were selected for the three new lines, like the LinaFlex pasteuriser, the Modulfill VFS-C filler for the canning line and the Modulfill HES for the glass lines, as well as a VarioClean CIP system. A supply system for the bottle washer, tunnel pasteuriser and CIP system, in which hot water replaces steam as the energy source, permits ultra-efficient distribution throughout the brewery. This enables energy from the processing area of the brewery to be recycled in the packaging department, so it does not have to be generated. It was this efficient, low-energy Krones system with its resource-economical media supply that instantly convinced Bavaria.

Besides, all relevant contact persons – from commissioning right through to maintenance – are close at hand, at the Krones Andina subsidiary in Colombia’s capital Bogotá. This local skill set enables Krones to respond to its customers’ individual needs even faster and better.

| Project: | Filling and packaging technology for a new greenfield brewery |

| Customer: | Bavaria & CIA S.C.A. |

| Location: | Barranquilla, Colombia |

| Commissioning: | 2024 |

| Scope: |

Turnkey canning line, rated at 120,000 cans per hour and two returnable-glass lines, rated at 66,000 and 72,000 bottles per hour respectively Canning line for 0.33- and 0.5-litre cans

Two returnable-glass lines for 0.33- and 1-litre bottles

|

The new glass lines have primarily been configured for producing the Águila brand, one of them for large 1.0-litre bottles in particular, an idiosyncrasy of the South American market where people are fond of sharing their drink with friends. This bottle size has become more and more popular ever since convivial get-togethers have at long last been possible again, following the end of the coronavirus pandemic. Production on the new lines in Barranquilla is scheduled to start in mid-2024.