It is referring to “intelligent networking of machines and sequences used in an industrial setting with the aid of information and communications technology“

Taking the step into a digital environment makes a lot of sense for companies on many levels. It can be used to design production sequences more efficiently and to optimally plan and make use of existing resources (systems, materials, employees, etc.) Collecting and analysing data from ongoing production allows sequences to be designed more flexibly and with the greatest possible degree of automation. They are then also less susceptible to malfunctions or stops. In short: Digital production helps uncover a wealth of optimisation potential –and this is precisely why it is one of the greatest forces adding impetus to and influencing the production of the future.

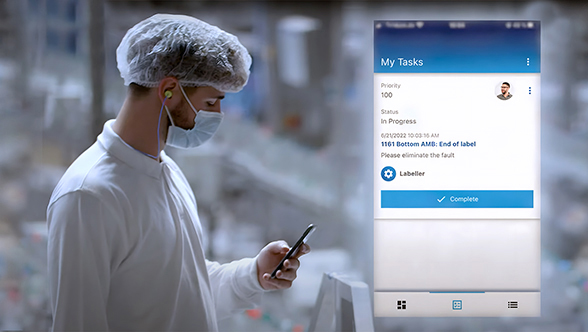

However, you do not need to look too far ahead to find such potential. As in many other industries, the food and beverage industry is already home to a large number of digital solutions along the value chain today. The only prerequisite: The willingness to embrace and accomplish such a digital transformation.