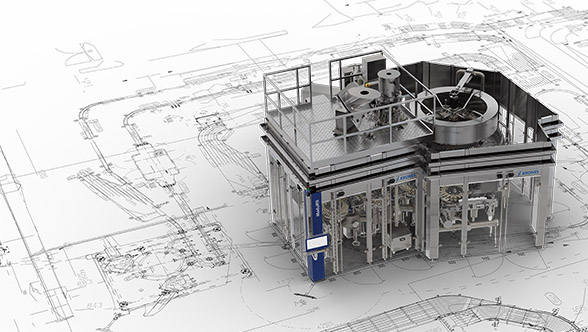

In this first module, spent grains, malt dust and yeast are processed to extract a liquid protein solution known as protein hydrolysate. For this, the mash runs through a colloid mill and a membrane filter. “We’d never worked with these two pieces of equipment before, so we first had to get a handle on the technology. But after a series of trials, we were able to do just that,” says Dr. Ralph Schneid, who is in charge of product development at Steinecker. In fact, the Steinecker team didn’t just meet the target metrics – in many cases they exceeded them. “The quality of the hydrolysate is very good – 55 percent of the amino acids we are obtaining are essential amino acids,” says Schneid.