Staying flexible in beverage manufacturing

Room for creativity and innovation

Sweet, fruity, sour or bitter: the syrup room is the starting point for innovative taste sensations which your product designers repeatedly manage to conjure up. Perfect working conditions for mixing new flavour nuances and developing successful products have many benefits. For they provide the foundations for your products’ market success, and this already during the first step in the production process.

At a glance

- Concept for the preparation of beverage ingredients

- Preparation of powder, liquid or frozen raw ingredients to form the most diverse products

- Production of finished products and finished syrups for further processing

- Can be flexibly extended thanks to modularly arranged units

- The output range can be individually adjusted to suit your line output

Modular design

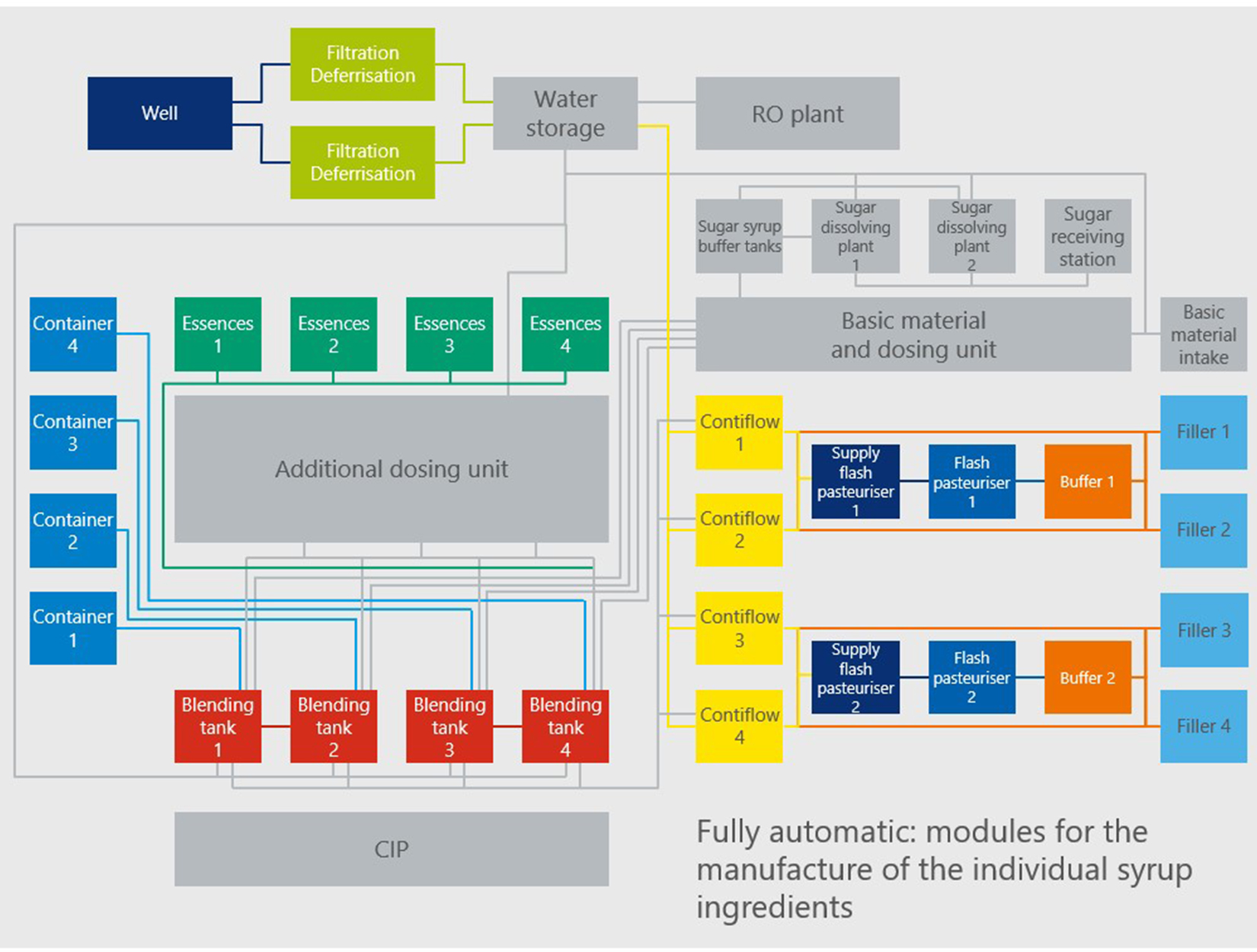

All elements of syrup manufacture are coherently combined with one another in the Krones concept. Depending on the manufacturing philosophy applied, production is performed either continuously or in batches.

Step by step to product success

- With the Hydronomic water treatment system, Krones is offering an individually customised system which has the right technology at the ready for many applications.

- The essential elements of syrup manufacture are the sugar dissolver and the sugar syrup pasteuriser. They are designed in accordance with the requirements on efficiency, flexibility, precision and modularity.

- The concentrate station and the powder dissolving station process ready-to-use concentrates and essences, as well as food acids in crystalline or powder form.

- Three mixing concepts are available:

- Batch mixing of the individual components with the downstream Contiflow mixer for finished-product manufacture

- Fully automatic, recipe-controlled Multiblend mixing system combined with a Contiflow mixer

- Contiflow as a multi-ingredient mixer which combines syrup mixing and finished-product manufacture

Design features

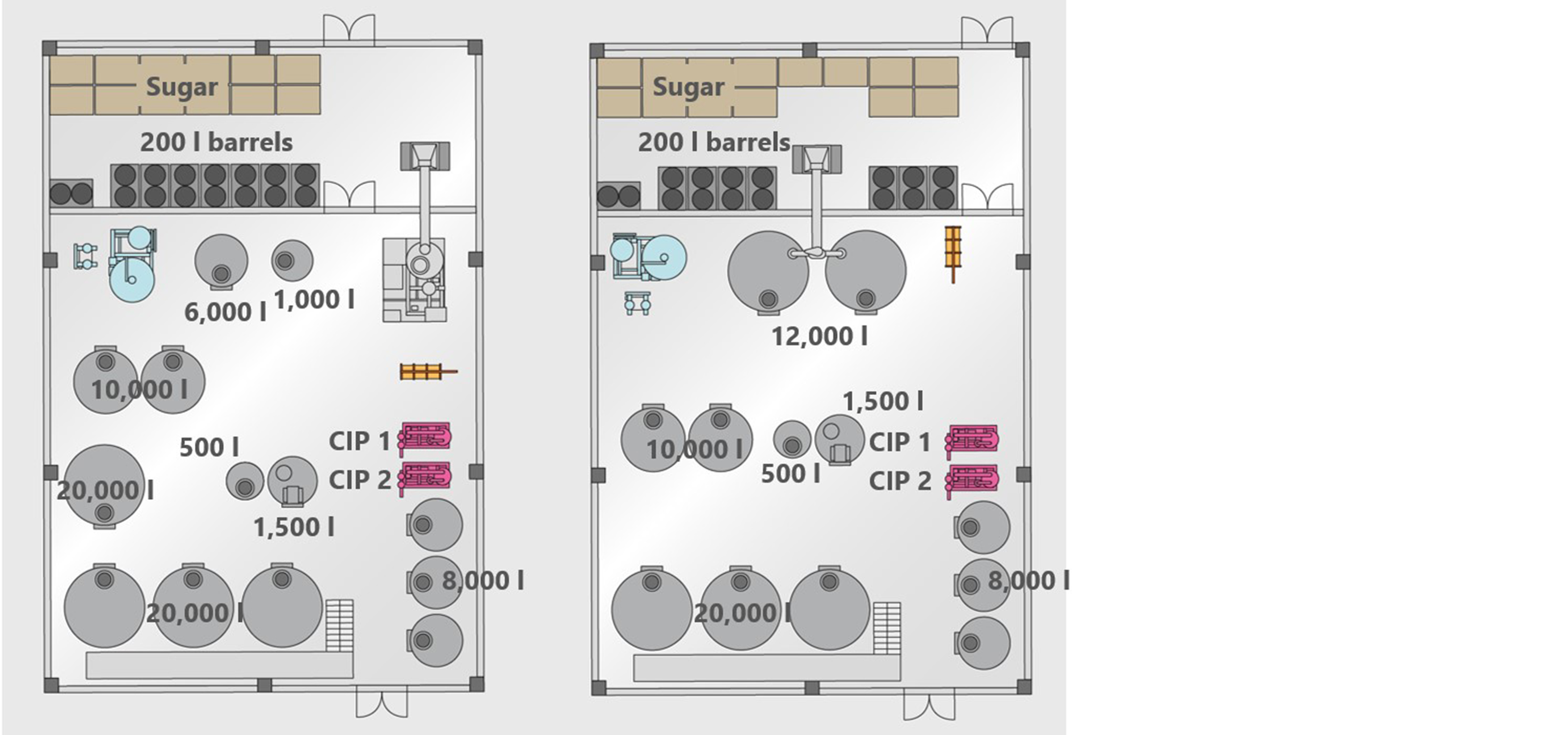

The basic idea behind the Krones concept is to design the syrup room as a group of compact modular units which can be expanded in line with the product range and performance spectrum.

- Pre-assembled frame structure with pre-installed connection for linking up to the existing infrastructure

- Krones filtration system

- Ion exchanger or activated carbon filter for refining the sugar syrup as an additional option

- Inline multi-ingredient mixer for semi-finished and finished products

- Inline mixing of finished products with carbonation

- CIP systems and cleaning concepts

- Evoguard valve and pump technology

Benefits to you

Everything from a single source

All the steps involved in the production of soft drinks – from syrup and mixing, right through to filling and packaging – are available from a single source. This is a major advantage which saves time during line planning, execution and maintenance.

Individual design

The Krones syrup room design is an individual concept based on defined modules and then tailored to meet your requirements.

Shortened sugar dissolving time

The innovative design of the infeed nozzle already ensures that the sugar is optimally mixed and distributed. This benefits you in three ways: a shorter dissolving time and therefore quicker production cycles, a more compact dissolving tank and lower energy costs.

Comprehensive connectivity

The top-level design for the control and planning software of the Krones MES means that all stock levels and all production flows can be supplied with all the necessary information from the syrup room.

Utmost precision

All components are characterised by the highest precision in the processing of the various basic ingredients – meaning you can rely on an accurate system with precise processing of the individual syrup and product components.

Quick installation with plug and play

The pre-assembled modules can be assembled and started up within the shortest period of time – and you have access to an immediately available system.