Knowing exactly what they want

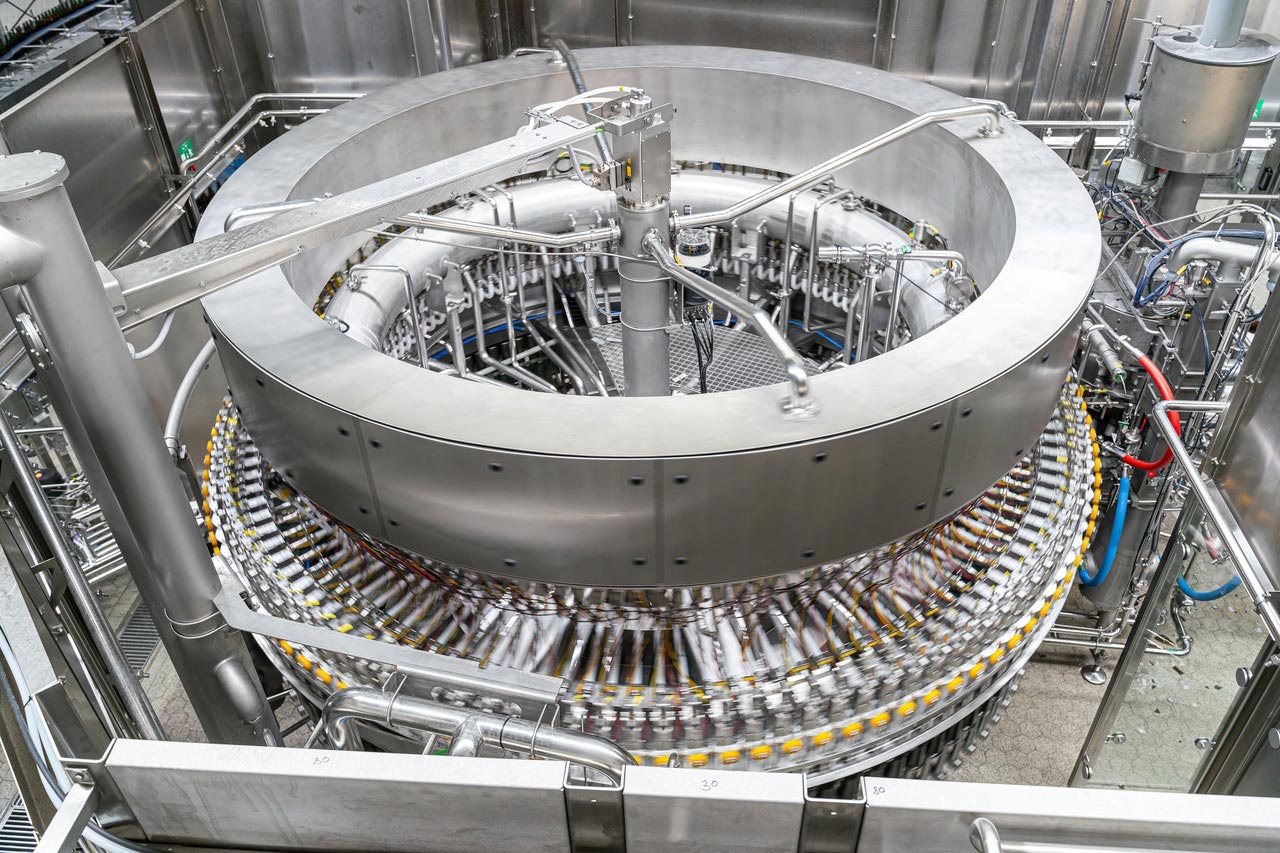

The Modulfill HES handles the brewery’s complete beer portfolio and, depending on the season, is operated for one or one and a half shifts a day. So as to remove any living yeasts that may be left in the machine after a bottle has broken, an automatic hot-water cleaning routine is run every two hours. This requires perfect interaction between the filler and the CIP system, so as to meet the brewery’s meticulous specifications. “We don’t want to put disinfectant in the filler for an interim cleaning routine,” explains Hans-Peter Drexler. “So it was important to us that the water invariably has the same temperature, of 80 degrees Celsius, right from the first litre.”

There were likewise some customer-specific requirements to satisfy in terms of CIP system design: “Since we’re not pasteurising our products, we had some special wishes in regard to valve technology,” points out Hans-Peter Drexler. “Our specifications lay down a certain valve type for every task. Krones took that into due account and integrated into the valve rack precisely those components we’re working with here as a standard.”

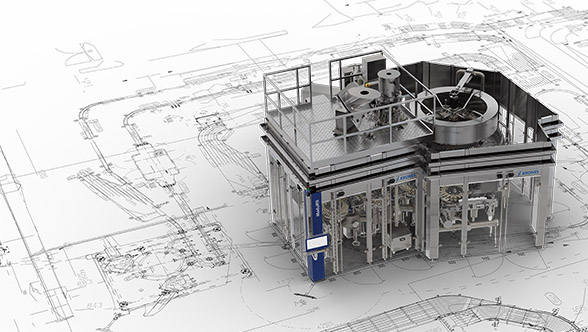

A lot of ingenuity was needed to fit the new machines into the hall. This was because the filler and CIP system were to be integrated into the existing line in the same space formerly occupied by two older models – and these were significantly smaller. “A whole lot of customisation work was required here, both in the planning stage and during erection as well,” says Hans-Peter Drexler. “But that was likewise solved to our satisfaction.” To accommodate the machines in the space envisaged, the Krones designers modified a number of individual features, including the housing of the filler and the position of the process components.