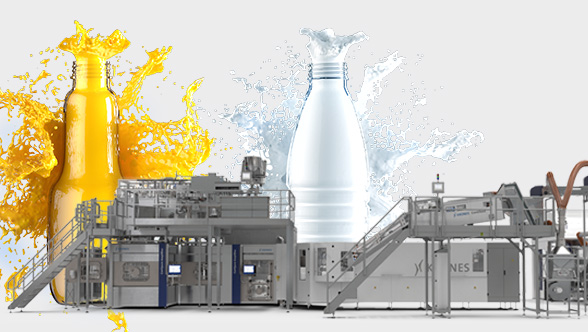

The biggest changes were planned for the firm’s largest facility, in Rugby: thanks to its central location in the heart of England, it constitutes a perfect hub for the distribution operations, but the existing equipment no longer sufficed to meet future requirements: “The old lines were running slowly, and were not very efficient in terms of water and energy consumption. Which is why we decided to install a total of seven new lines and a high-bay warehouse,” says Clive Hooper. Krones supplied the four PET lines, while the fully automated high-bay warehouse came from its Italian subsidiary System Logistics.

“When we chose Krones as the vendor for the PET lines, it was immediately clear that the high-bay warehouse, too, was going to be from System Logistics. This was because we wanted to single-source both production and logistics – and Krones with its House of Krones was offering the ideal complete package,” is how Clive Hooper sums up the situation.

We wanted to single-source both production and logistics – and Krones with its House of Krones was offering the ideal complete package.

Clive HooperChief Supply Chain Officer

Clive HooperChief Supply Chain Officer