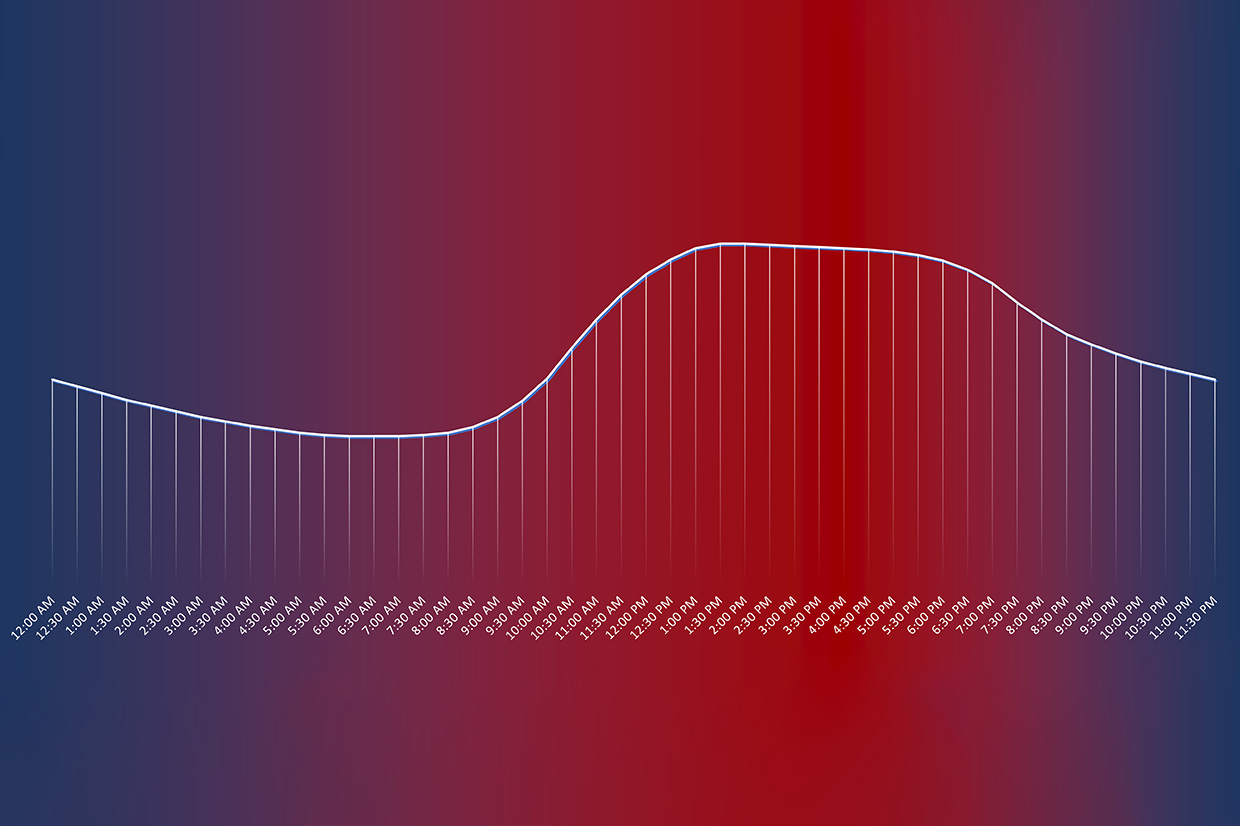

The challenges associated with manufacturing PET containers are varied and complex. Process windows are short, and even the daily changes in ambient temperature and humidity in the production hall require regular manual adjustments to various process parameters to ensure the required level of container quality.

Steadily increasing production speeds present another challenge: While the maximum output per blowing station was still at 1,600 containers per hour back in 2000, today’s stations are capable of making up to 2,750 bottles per hour. So, a machine can turn out as many as 100,000 containers per hour. Of course, at such high speeds, even the slightest deviations from ideal conditions can quickly and significantly impact an entire production run.