“The challenges posed for packaging have changed over recent decades. Our products have to meet ever-growing expectations and requirements, and that calls for a constant stream of fresh solutions,” explains Kim Cheng, Managing Director of the German Packaging Institute which organises the competition every year. “What hasn’t changed, though,” she continues, “is the pivotal role that packaging plays for our well-being and health and for a reliable supply of fast-moving consumer goods. So it’s all the more important that our sector never slackens its efforts to live up to this vital task by demonstrating outstanding innovative vigour, regardless of all the crises and challenges it has to overcome. The large number of innovations submitted for the German Packaging Prize 2023 and the solutions receiving an award once again bear eloquent witness to that.”

Less is more: The extremely lightweight bottle developed by Krones makes for a substantial reduction in PET consumption. The jury of the German Packaging Prize has recently honoured this design with an award.

German Packaging Prize

The competition organised by the German Packaging Institute is open to all materials and acknowledged as the biggest European stage for showcasing solutions themed around future-driven packaging. This year, accolades went to 34 innovations from England, Germany, Austria and the Netherlands.

The range of new concepts submitted was huge: Whether for aluminium, plastic, wood or cardboard, for software or machines, for tubes, cans, boxes, padding, plus transport, secondary or sales packaging, the creative solutions presented by the competition’s participants were many and varied.

Highly practical and ultra-lightweight

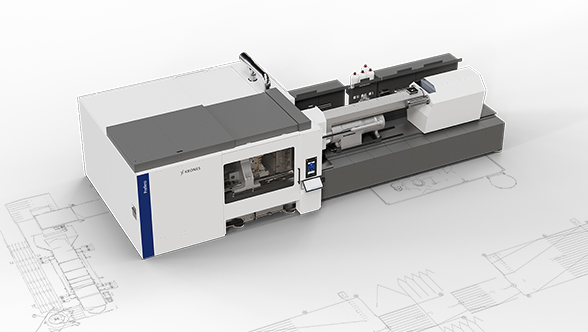

Sustainability, the circular economy, as well as climate and environmental protection were once again among the main priorities targeted by the solutions submitted in 2023. And this was where Krones scored with its 500-millilitre ShoulderFlex bottle made of PET.

When developing this ultra-light 500-millilitre water bottle, for which the preforms are produced in a mould made by Krones' subsidiary MHT, the team achieved yet another substantial weight reduction. Thanks to the new design, it was possible to reach a bottle weight of under six grams. That makes a crucial contribution towards reducing the carbon footprint of water bottlers by yielding material savings of up to 50 per cent compared to conventional water bottles on the market.

The revolutionary bottle design can be used to make containers that are sustainable and weigh very little, but its advantages are also apparent during the bottle production and processing stages because the bottles can be reliably stacked even without the stabilising effect of nitrogen pressurisation, with a filled topload of up to 40 kilograms.

“Responsible use of packaging materials also includes developing sustainable packaging solutions that are not only resource-economical but also practicable. ShoulderFlex meets those requirements in full,” explain Martin Loistl from LCS Container Design and Jochen Forsthövel from Plastics Technology, both members of the development team. “Despite the smaller amounts of PET needed to produce them, these containers are in no way inferior to conventional bottles currently on the market as far as stability and convenience are concerned.” But our development people do not stop here and are now busily improving and fine-tuning the bottle’s design. So we can definitely look forward to seeing what new records they will be coming up with next.

Andreas Domma