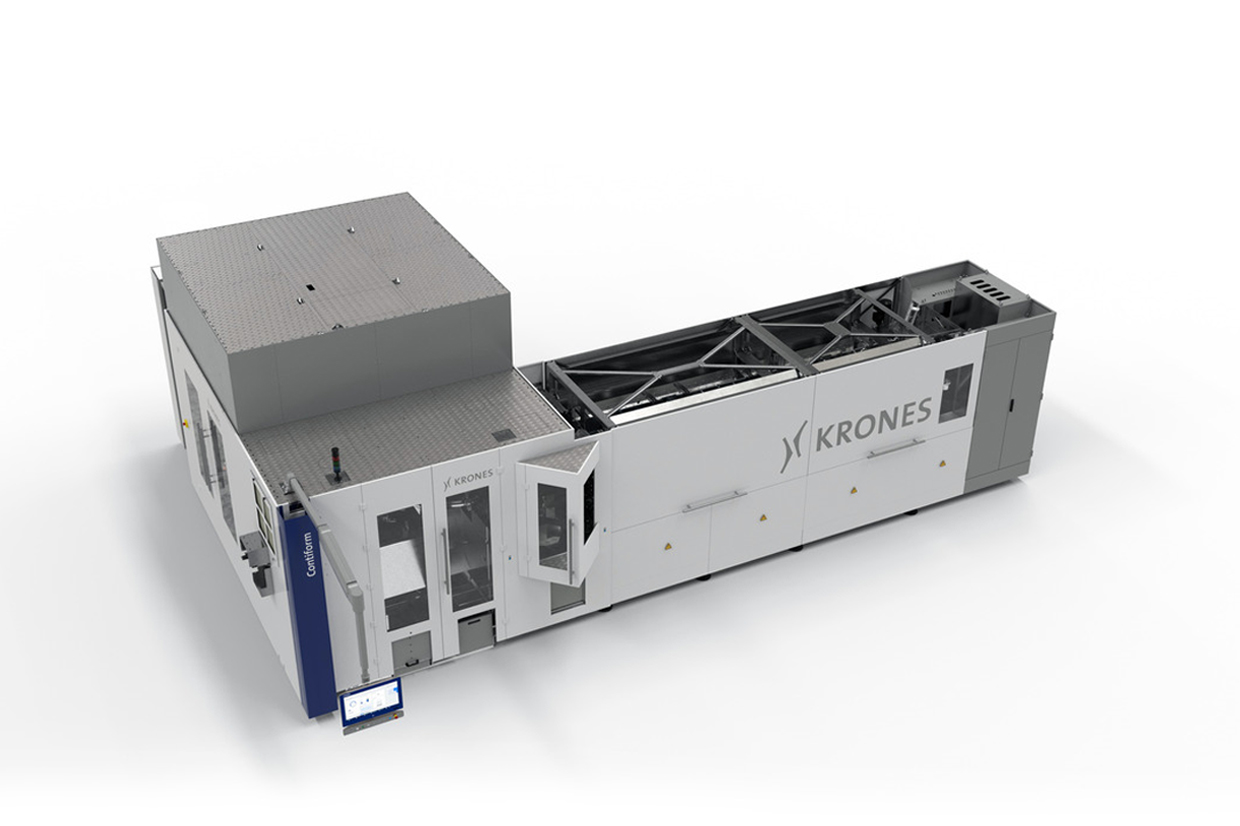

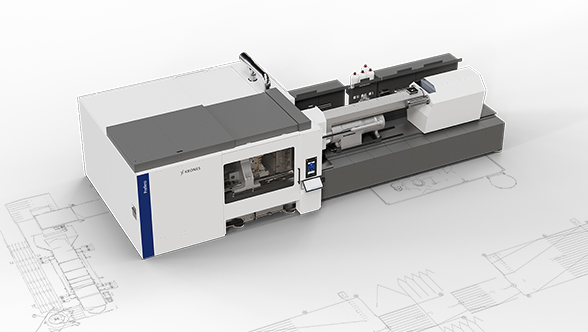

With its high energy efficiency and ability to handle rPET preforms, it would seem that the fourth generation of our Contiform stretch blow molder has already exhausted all of the possibilities for maximizing sustainability. But our smart, thrift-focused development team figures there is always room for improvement. And so, they took a long hard look at the machine’s upstream emissions.

They asked themselves which components could be modified and whether there are alternatives that entail lower emissions as they conducted a bottom-up analysis of the Contiform. And what they found was this: The transparent protective panels could just as well be manufactured from material that has a smaller carbon footprint. So, with the necessary changes in place, these panels are now made of polycarbonate with an average recycled content of 85 percent as standard. Various smaller parts, such as covers, already contained 100 percent recycled material.