One hundred percent precision when filling still and sparkling wine into glass bottles

Modulfill HRS short-tube filler with correction function and automatic filling tube adjustment

- Reliable fill level determination via the vent tube

- Low-oxygen filling through several pre-evacuation steps with intermediary CO2 flushing

- Electropneumatically controlled filling valve

- Fill level correction via separate correction channel

- One filling speed

- Automatic swinging-in of the CIP cups

Field of applications

- Suitable for still wine and sparkling wine

Output

- Up to 60,000 containers per hour

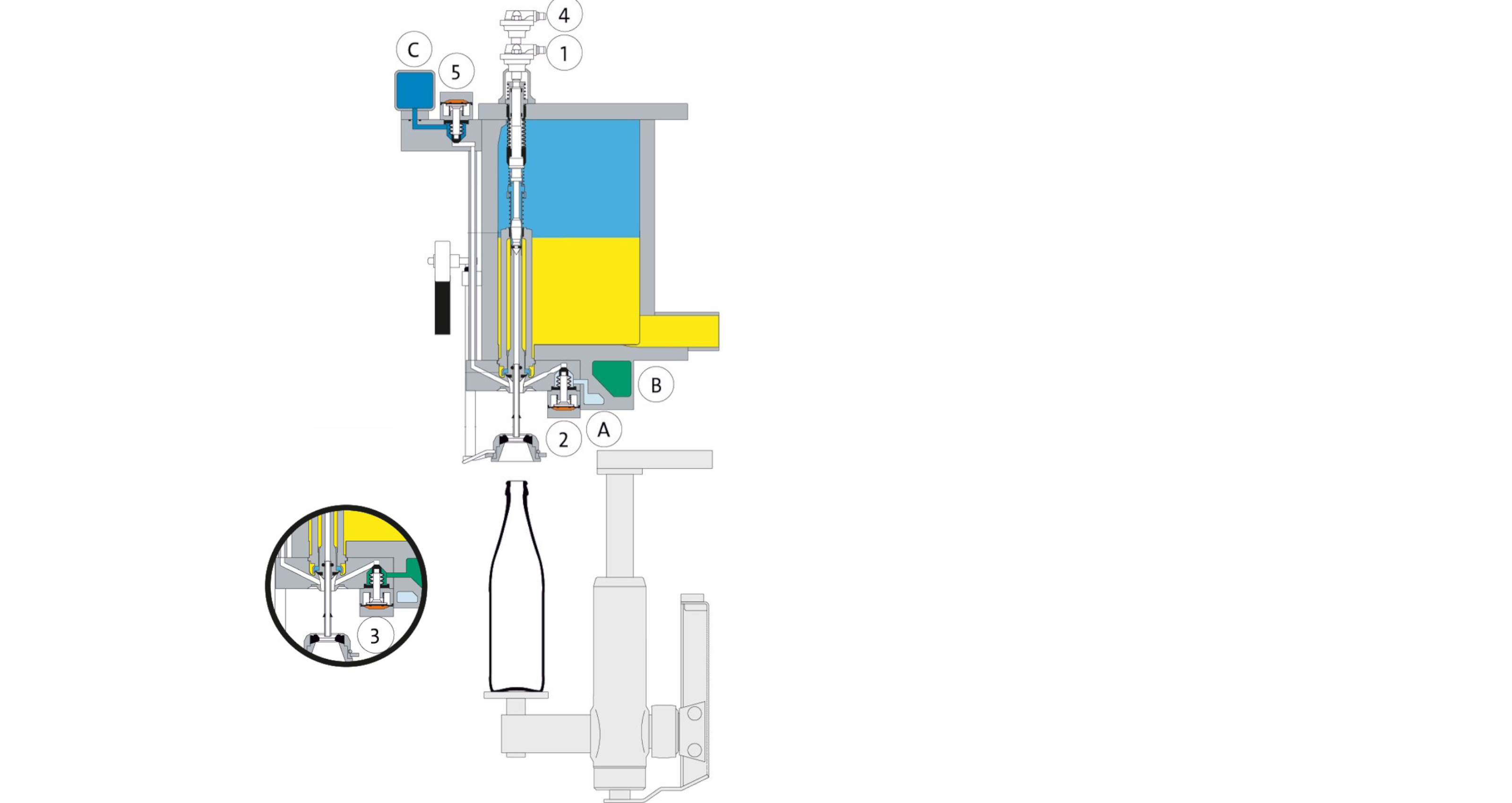

Functional principle of the valve

The lift cylinder presses the bottle on to the filling valve where it is pre-evacuated several times. With non-carbonated beverages, the filling valve opens due to a movement of the control cylinder. With carbonated beverages, the bottle is pressurised and the valve opens as soon as the bottle and the ring bowl have the same pressure. At both of the filling processes, the liquid runs through a spreader along the bottle wall. The valve closes as soon as the bottle is entirely filled. The correction channel opens and the excessive fill quantity is displaced from the bottle up to the end of the vent tube. With carbonated beverages, a snifting phase is performed in order to reduce the pressure in the bottle head space. Non-carbonated beverages can be removed from the filling valve right after filling is completed.

Bottle volume 200 to 2,000 ml

Viscosity < 10 mPa·s

Pulp max. 0.1 x 0.1 x 0.1 mm/portion < 5 %

Benefits to you

Best technological values

- Several pre-evacuations of the bottle for the least possible oxygen intake

- No product returned into the ring bowl during the correction phase

Maximum filling accuracy

- Determination of the fill level by means of the length of the vent tube

- Separate correction channel: Any excess product is pushed out of the bottle and up to the end of the vent tube.

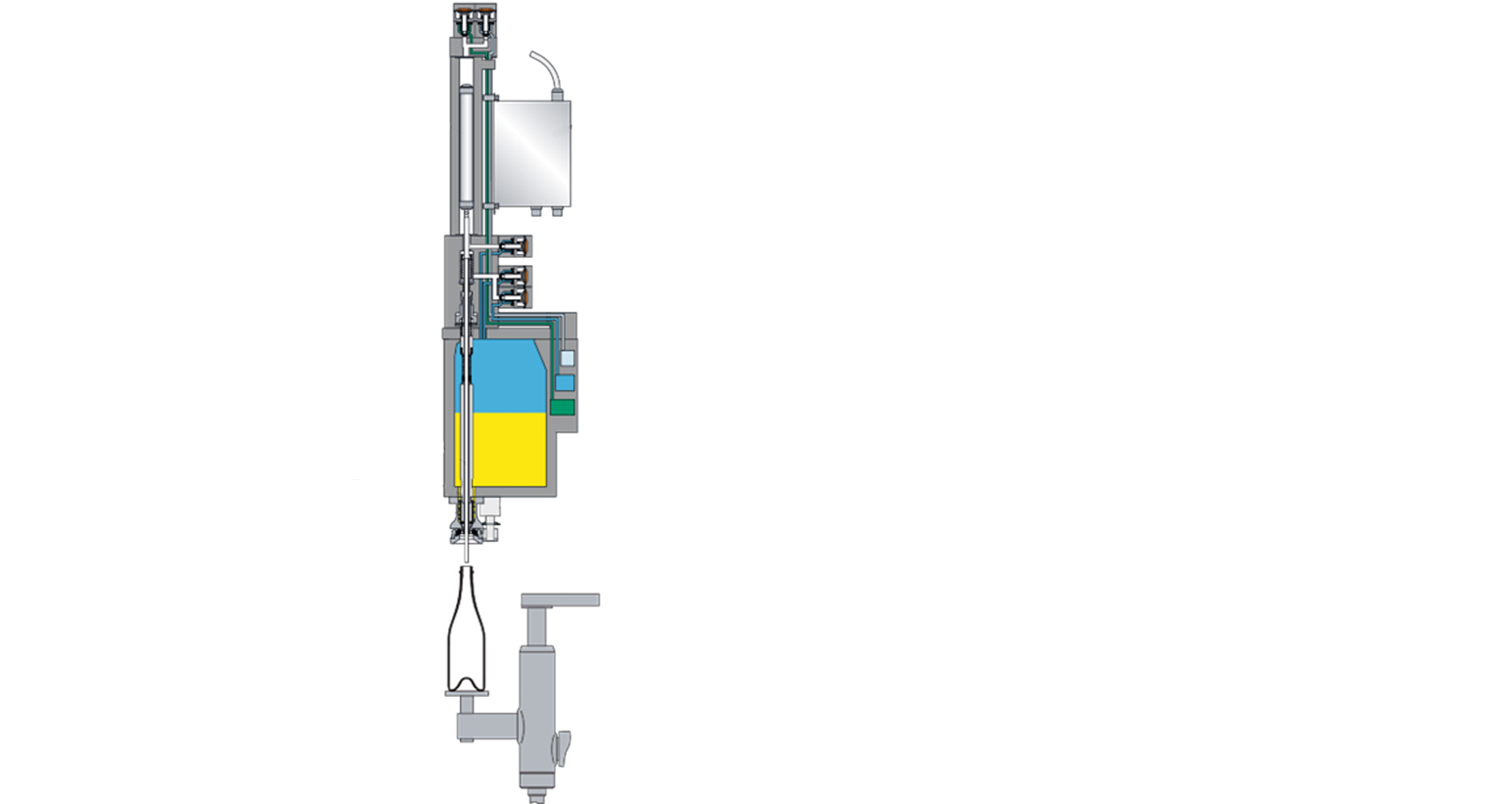

First the glass bottle is pressed on and then it is pre-evacuated several times. The filling valve opens after pressurisation and the filling process begins: The product runs into the bottle via a swirl insert. Once the bottle is filled up to the brim, the valve closes electropneumatically. The correction channel opens and the excessive fill quantity is displaced from the bottle up to the end of the vent tube. Afterwards, the bottle is snifted via a channel. The special feature of this version: Both, the vent tube adjustment and the swinging-in of the CIP cups are performed fully automatically.

Bottle volume 200 to 2,000 ml

Viscosity < 10 mPa·s

Pulp max. 0.1 x 0.1 x 0.1 mm/portion < 5 %

Benefits to you

Best technological values

- Pre-evacuation of the bottle for least possible oxygen intake

- No product return to the ring bowl during the correction phase

Foam-free filling

- Use of swirl inserts at the filling valve outlet

Maximum filling accuracy

- Fill level is determined by the length of the vent tube

- Separate correction channel: Any excess product is pushed out of the bottle and up to the end of the vent tube.

Version in fully automatic design

- Automatic adjustment of the vent tube length

- CIP cups can be automatically swung-in