Digital operator support in your line

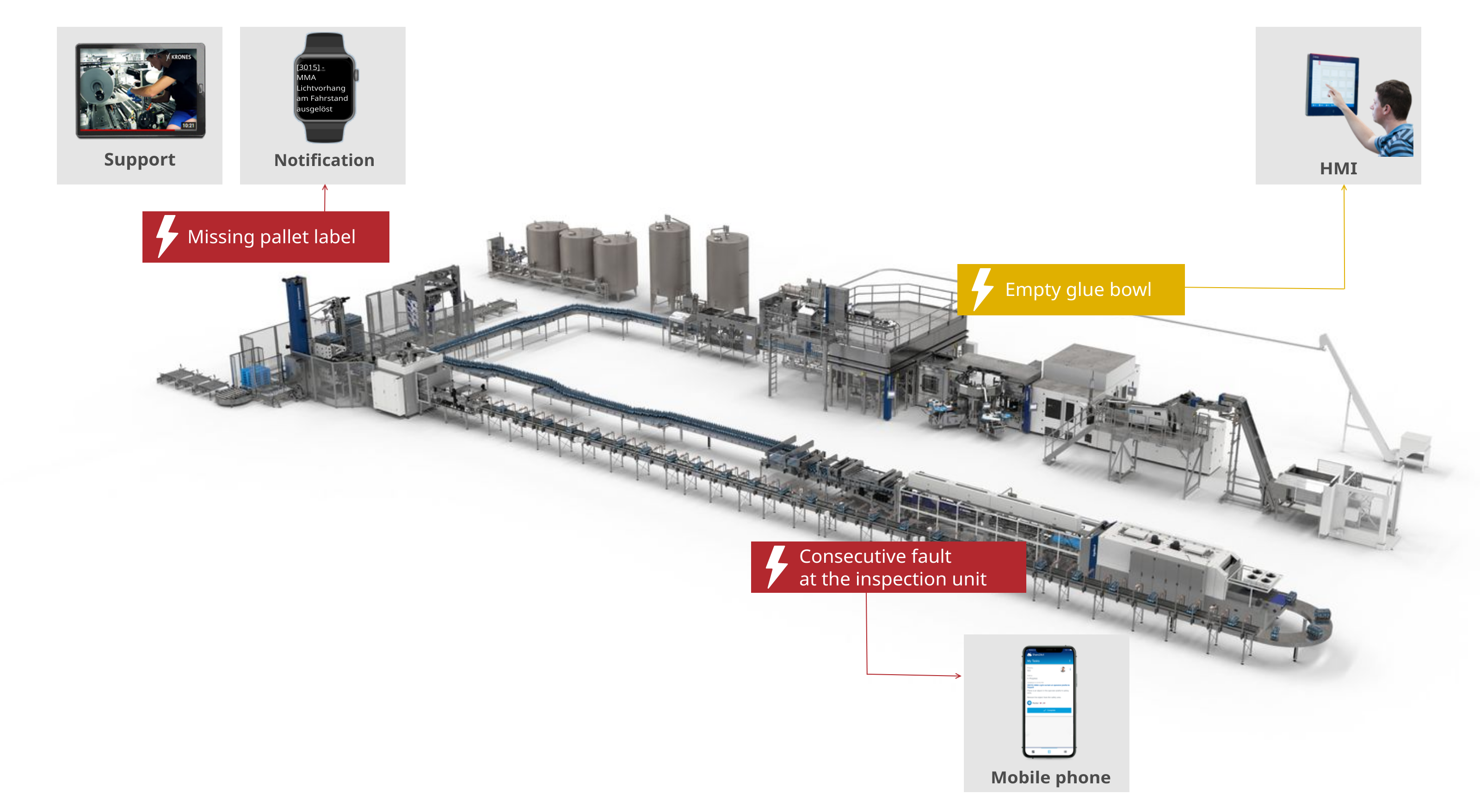

As an operating company, you can use Shopfloor Guidance to simplify the organisation, prioritisation, management and documentation of all pending tasks. Changes to the machine status are discovered early: Information regarding downtimes or missing raw materials and supplies are detected by the system and measures are directly derived. Shopfloor Guidance automatically groups and prioritises all the necessary interventions and actively informs the employee responsible – thus helping avoid machine downtimes.

At a glance:

- Provides support in the organisation, prioritisation, management and documentation of all activities in the company

- Groups and prioritises tasks and assigns them to a user

- Monitors defined limit values within production

- Displays changes to the machine status in the early stages

Active notification for relevant interventions

Use Case: Pasteuriser

- The operator is actively informed once regular quality and process monitoring has been completed

Use Case: Filler

- Ensuring that each filling valve and all product and gas channels have been cleaned (measures the success of the cleaning process)

- Measurement of the oxygen level in the product tank to guarantee the beer batches are of a high quality

Use Case: Labeller

- Monitoring of the glue supply in the glue container for the avoidance of downtimes due to a lack of materials

- Monitoring of labels for the avoidance of downtimes due to a lack of materials

- Flow meter for monitoring the air consumption for the detection of incorrect settings, faults and leakages (entire machine and labelling stations)

Use Case: Blow moulder

- Continuous monitoring of the pressure dew point temperature during the blowing sequence to ensure a high bottle quality

- Active notification if the machine is stopped, regardless of where the operator is in the line

- Active notification if materials are required, regardless of where the operator is in the line

- Grouping and prioritisation of all necessary interventions

- Escalation path in the case of non-observance

- Forwarding option

- Condition monitoring: Useful and proven use cases already integrated

- Additional support if required: Context-related instructions

Shopfloor Guidance in detail

Monitoring of machine conditions

Independent creation and management of alarms

It is possible to create a user-defined alarm. The following information is stored in it:

- Data point to be monitored

- Threshold value and its rule violation (“>” or “<“ than the threshold value)

- Form of notification:

- by text message and/or

- activation of a maintenance order (if the Assistance service has been booked)

It is always possible to view the settings for an alarm and make adjustments.

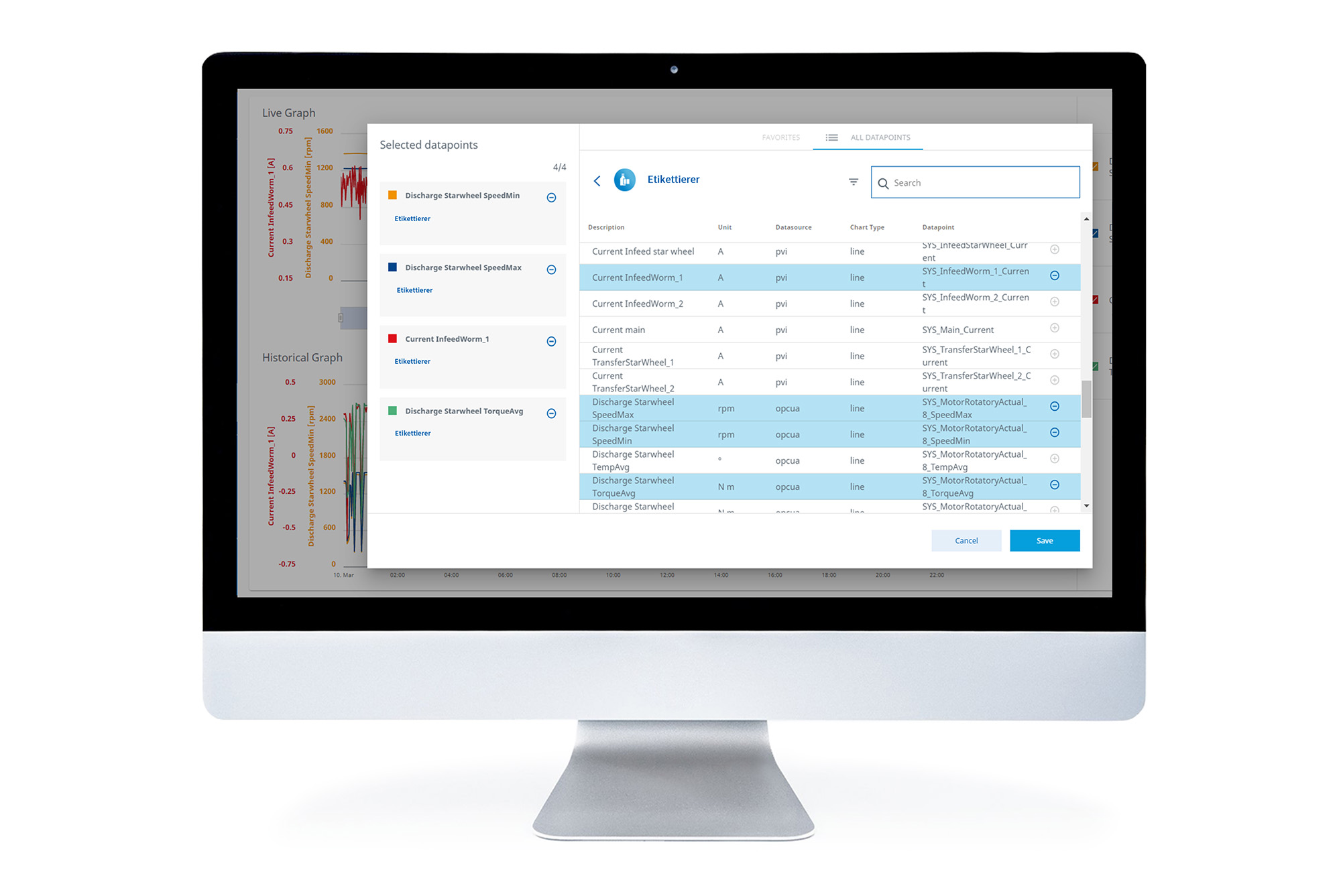

Visualisation of machine data

The selected data points are visualised with a line diagram:

- Selection of data points

- per machine

- across multiple machines

- Filtering of individual data points possible

- Various options for displaying data:

- Real time

- Aggregated over the last hour, the last eight or 24 hours

- Manually selected period

- Simplified data observation through the mouse-over and zoom function

- Possibility of data export (csv file)

- Analysis functions directly in the visualisation interface

Providing support in all areas of production

Benefits to you

Shortening downtimes

Shorten the time span in which employees are informed about relevant downtimes. Relevant downtimes refer to those where the machine does not restart automatically.

Minimum user inputs

Receive an overview of all of the interventions relevant at the current time. Completed tasks are automatically closed once the machine starts working again or the message has been reset.

Preventing downtimes

Prevent downtimes occurring due to a lack of raw materials and supplies (for example due to a lack of labels or warnings due to fallen bottles). Use critical machine information effectively in the entire process.

Direct notification

Use the app for mobile end devices to receive push notifications regarding assigned tasks and thus also work through your tasks irrespective of your location.

Collaboration

Create the conditions for efficient teamwork through the continuous synchronisation of the task status and always see who is working on what and may possibly require support.

Keep track

Work with a tool which helps you to manage, structure and complete your tasks. Create your own rules for monitoring limit values depending on the requirements.