Up until the early 1990s, the company produced exclusively this one type of mustard, “right in the heart of Regensburg’s old city centre, made by hand, full female power ahead,” says Wunderlich with a wry grin. Ernestine Flietel was part of the production team back then. She is the last member of the crew who is still working and has been part of the Händlmaier family for 33 years now. She has fond memories of her early days in the company: “At the time, there were about ten or twelve women in our team. We did everything ourselves: mixing and boiling the mustard, filling it into jars and labelling them, right through to loading the goods onto the delivery vehicles. To be honest, it was quite strenuous, especially for us women. But it was a happy time, working in a great, family-like atmosphere. And it’s still the same relaxed atmosphere today.”

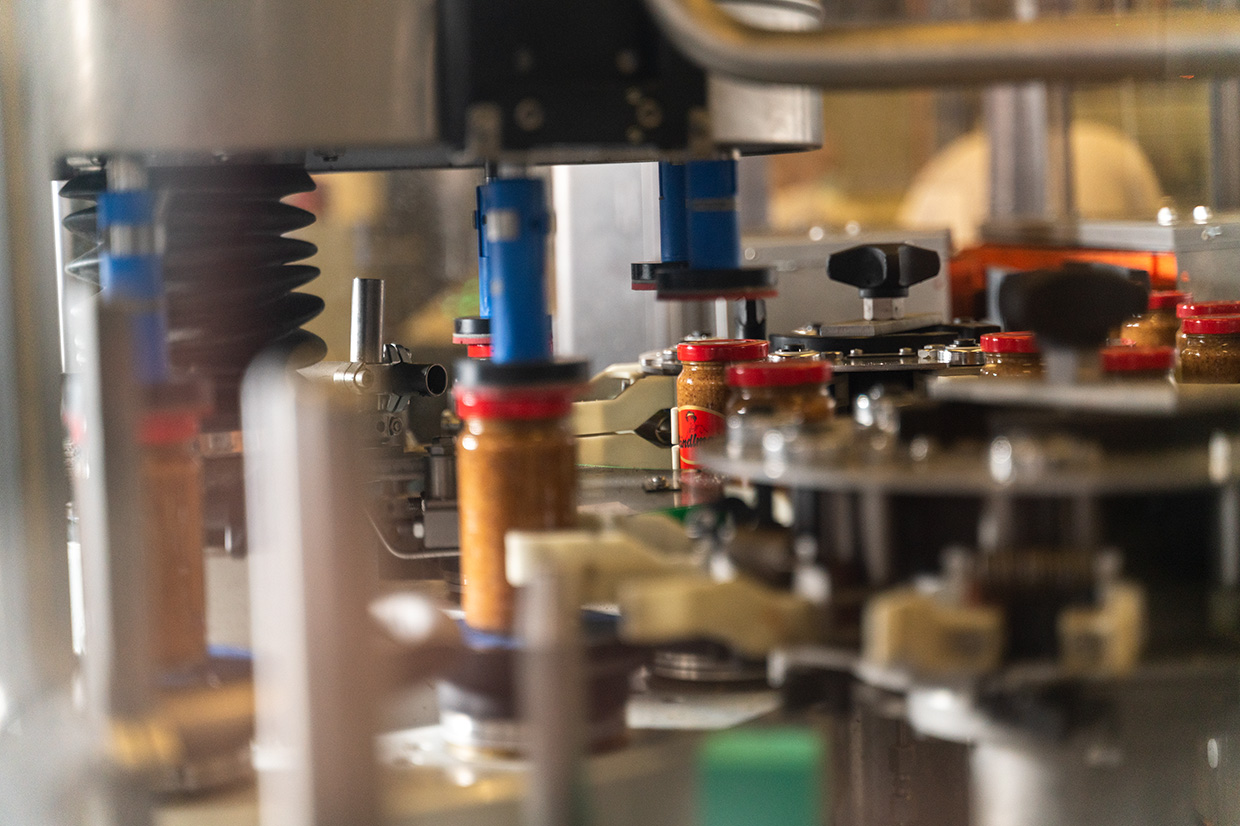

In the early 1990s, however, Händlmaier moved away from a purely manual model. The company decided to update and automate its manufacturing processes and invested in production and filling lines. But since the building in the city centre was too small to accommodate the equipment planned, in 1991 Händlmaier moved to premises on the outskirts of Regensburg. And this was when Händlmaier’s success story really picked up speed.