When in 1991 Jürgen Nordmann took over the Stralsund-based brewery after German reunification, it was brewing its beers mainly for the local market. However, Jürgen Nordmann was fully aware of his brewery’s true potential – and in 2012 decided to go for a complete revamp. This U-turn included not only a new name but likewise a stringent brand concept and an expansion of the existing portfolio. In the meantime, the Störtebeker Braumanufaktur has with its specialty beers made a name for itself throughout Germany. This approach has definitely resonated among German beer aficionados: within just eight years, the Störtebeker Braumanufaktur has increased its production output from 60,000 to a good 300,000 hectolitres and is today selling its beers almost nationwide at food and beverage retailers, and in the north of Germany likewise in the hospitality industry.

Overall responsibility for filling and logistics

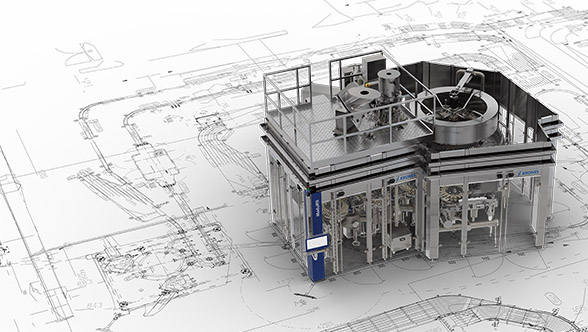

So as to actually achieve this target, however, Störtebeker had no alternative but to invest in its existing production landscape. In 2016, the company expanded its brewhouse capacities and then decided to increase output levels in the bottling hall as well while simultaneously optimising its logistical processes. For this purpose, Störtebeker purchased a 40,000-square-metre plot right next to its existing headquarters, where the company was able to translate its vision of a greenfield project into shopfloor reality. But for the brewery, with its payroll of just 110 in production and administration, this undertaking was truly a mammoth task. “Therefore, we decided to place the entire new construction work in the hands of two contractors: the first being the company building the hall and the second being Krones assuming overall responsibility for the technology involved,” explains Jürgen Nordmann.