The Market is booming. Soft drinks with natural exotic-fruit flavors are consumed in over 50 countries and especially popular in Europe. Kassatly Chtaura exports 35 percent of its Freez Mix to European countries. To better develop this market, Kassatly Chtaura established a subsidiary, Boutique Beverages Bottling International, in Cyprus in 2021. Here, a new 21,000-square-meter factory is being built on a 54,000 square meter plot, which will feature a 5,000-square-meter bottling hall. As in its existing factory in Lebanon, Kassatly Chtaura is putting a strong emphasis on sustainability at its Cyprus plant, which will include a one-megawatt solar installation to cover the plant’s growing energy needs and a fully automated waste water treatment system.

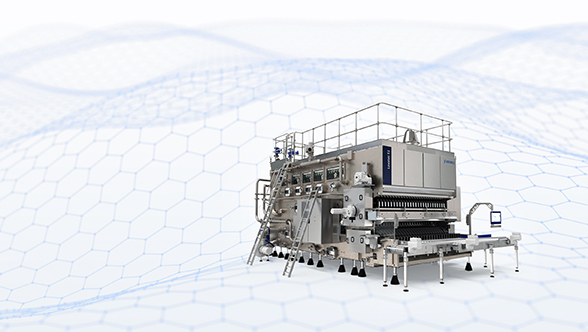

Boutique Beverages Bottling International