Even beyond ongoing production, the Dynafill offers a number of pluses. Thanks to the 2-in-1 design, there are no handling parts on or transfer starwheels to the crowner, which shortens changeover times and significantly reduces the time and effort involved in maintenance.

In terms of cleaning, the Dynafill is a clean and simple matter: The elimination of overfoaming not only saves valuable beer. It also keeps the production area clean. And when it does come time to run a cleaning, the filling valve and the crowning head are integrated into the CIP circuit thanks to the closed system.

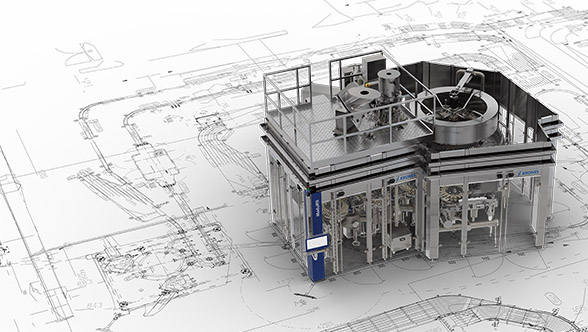

Because the filler and crowner form a single unit, the Dynafill requires far less space than a comparable conventional machine combination: The footprint is 50 percent smaller since neither a separate crowner nor the associated transfer starwheels are needed. And because the filler does not need to be emptied if there is a stoppage in the line, the buffer to the labeler can be shorter as well.