Special filler for water

Perfect for water with an ozone content from 0.5 ppm

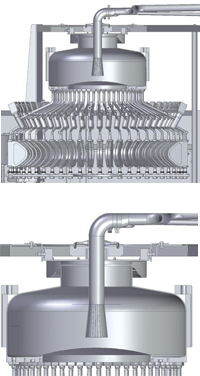

Krones developed the Hydrofill especially for filling non-carbonated water. The filler is designed to fit perfectly into Krones block solutions such as the Contiform Bloc or the ErgoBloc L.

At a glance

- Especially developed for filling non-carbonated water

- Every water type can be filled with or without conductivity: Perfect for water with an ozone content from ≥ 0.5 ppm

- Filling valve with mass flow meter and proportional flow regulator (PFR) for optimum flow speeds

- Fits ideally into Krones block solutions such as the Contiform Block or ErgoBloc L, including the appropriate capper

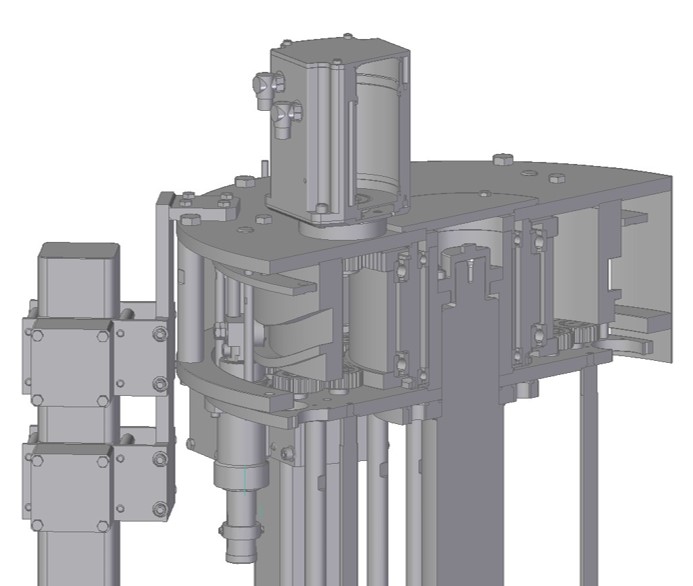

Krones Hydrofill as part of the Contiform Bloc

- Filling valve

- With mass flow meter for water without conductivity

- Design with PFR technology for infinite adjustment of the filling speed

- Pressureless product tank with sterile-air supply

- Interior cleaning of the system

- With trough

- Including CIP return pump

- Capper with central, servo-controlled head drive

- System for cap feed:

- Krones sorting system with cap inspection unit

- Krones Accucap technology for cap buffering

- Contiform 3 Pro stretch blow moulder

Components

Product tank design

- Pressureless product tank with sterile-air supply

- Product feed from top

- Integration of a special safety function in the control system to transmit a warning signal in the event of a malfunction in the sterile-air supply

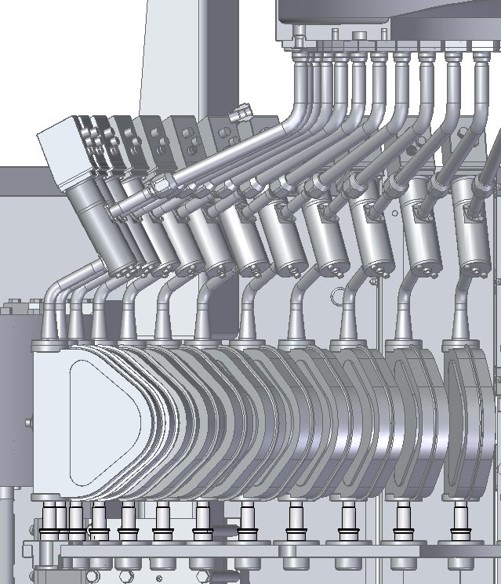

Filling valve design

- Filling valve especially designed for filling non-carbonated water

- equipped with a state-of-the-art mass flow meter

- best possible values for the standard deviation

- Filling process in full-jet mode for optimum microbiological safety

- Infinite adjustment of the filling speed by the Krones Proportional Flow Regulator (PFR)

- Latest technology for flow control during filling

- Only available at Krones

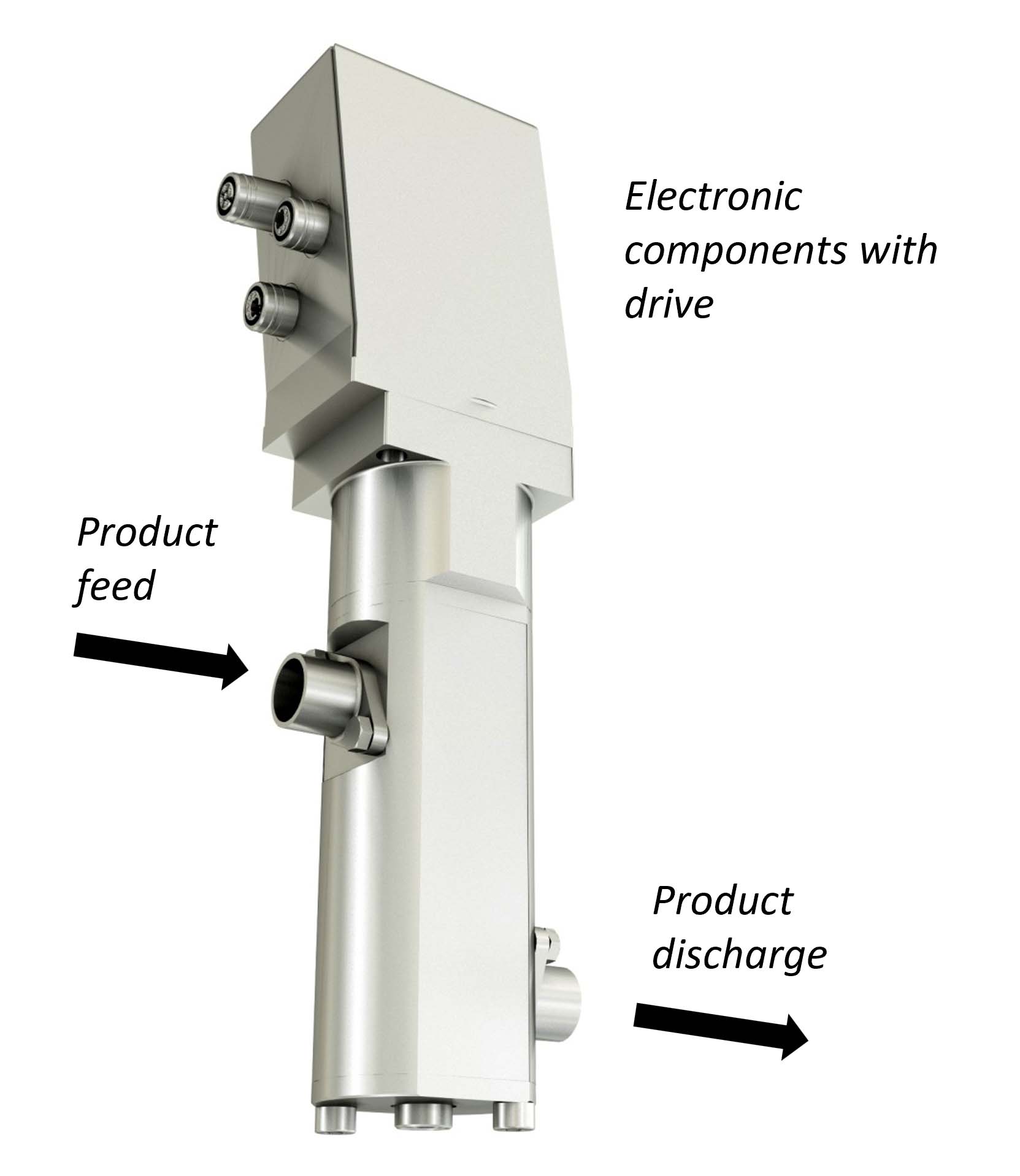

The PFR valve: Benefits to you

Optimum adjustment to all product-bottle combination

- Infinitely adjustable flow speed

- Utmost reproducibility due to the identical design of all filling valves

- Applicable for nearly all filling systems

Quickly ready for use

- Plug-and-play principle thanks to the simple, modular replacement of components without need for calibration

- Optimum machine start-up with valve function control and filling program change during start-up

Maximum operational reliability

- Direct monitoring of the valve position, ideal utilisation of the filling angle

- Early failure detection thanks to control current monitoring

Minimised maintenance effort

- Pre-connected lines, minimum wiring requirement

- Simplified troubleshooting as the mechanical and electronic components form a single unit

CIP cleaning

- Hygienic design of CIP program

- Draining of CIP medium via the open filling valves between the infeed and discharge starwheel into a trough

- CIP trough with a recirculation pump for returning CIP media into the CIP circuit

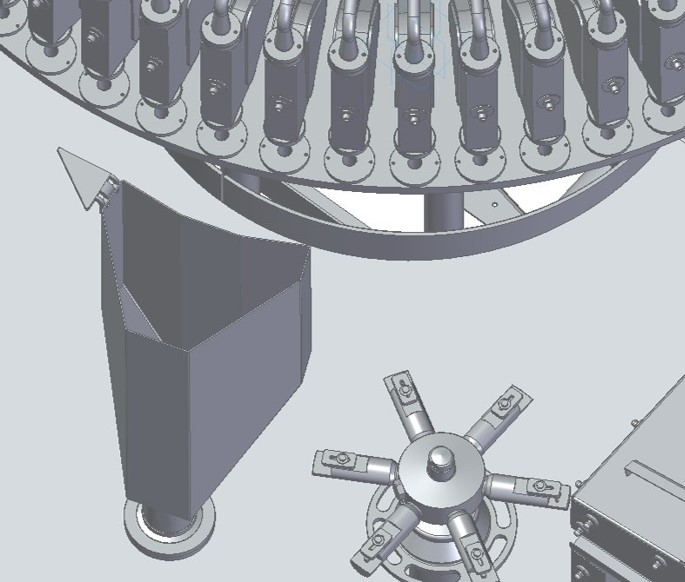

Capper

- Matched to the Krones Hydrofill water filler

- With servo drive technology

- The rotary motion is transferred via gears to the individual capping heads

- Cam and roller controlled vertical movement of the capping heads

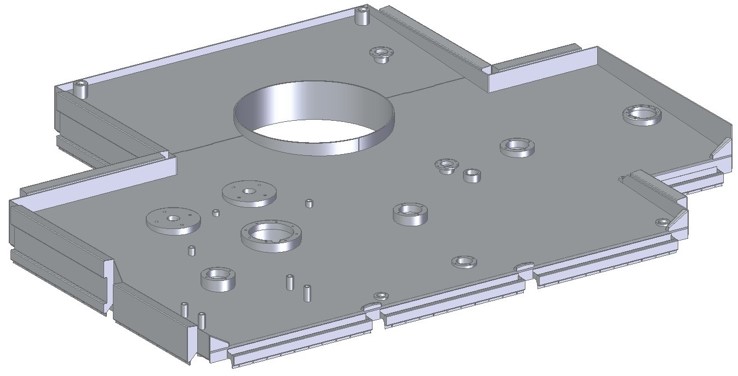

Machine table and guards

- Table top with slope on one side central draining point

- Very compact machine layout due to directly attached guards

- The complete system is provided with servo drives

Cap feed system

- Cap feed via Krones Capcade sorter

- Special Krones Checkmat CI inspection unit

- Intelligent sensor inspection unit

- Checks for ovality and cap orientation

- Buffers the sorted caps by means of Krones Accucap Ensures that the machine is emptied

Note: Cap sorter with Checkmat inspection system and Accucap cap buffer system is installed on a separate platform

Benefits to you

Safety for product and production

- Pressureless product tank with sterile-air supply

- Product feed from top

- Special safety function in the control system to transmit a warning signal in the event of a sterile atmosphere malfunction

The perfect technology for every water

- Filling valve with mass flow meter for water without conductivity

- Design with PFR technology for infinite adjustment of the filling speed

For the highest hygiene requirements

- Interior cleaning of the system with trough

- Including CIP return pump

Sophisticated technology - also in the capper

- Capper with central, servo-controlled head drive

- Cam and roller controlled vertical movement of the capping heads

How can we help you?

Additional information

Download

Do you have any questions?

Contact

Krones nearby you

Sales network

Come and visit us

Events