In late 2019, I moved to the product management team for our turnkey lines where I am now dedicating my efforts exclusively to our canning lines. Here, my job is to advise customers, in conjunction with the sales team, on all aspects of their future canning line, to identify development potential in our talks, and to incorporate it in our development roadmap.

The good old beverage can. It was developed in the USA in 1935, and nearly struck down in Germany in 2003 when the deposit on cans was introduced. Now, 18 years later, cans are downright booming – even in Germany and indeed all over the world. The can stands for handiness, is much in demand in design and marketing circles, and turns out to be a genuine sustainability champion. A recently published study reveals that only 0.03 % of all beverage cans in Germany end up in our natural environment, while 99.3 % of the aluminium cans in common use find their way back into the recycling loop. Globally speaking, the can has one major advantage over other types of packaging, in that its base material as such, aluminium, has a relatively high recycling value and therefore offers an incentive for recycling even without a deposit system.

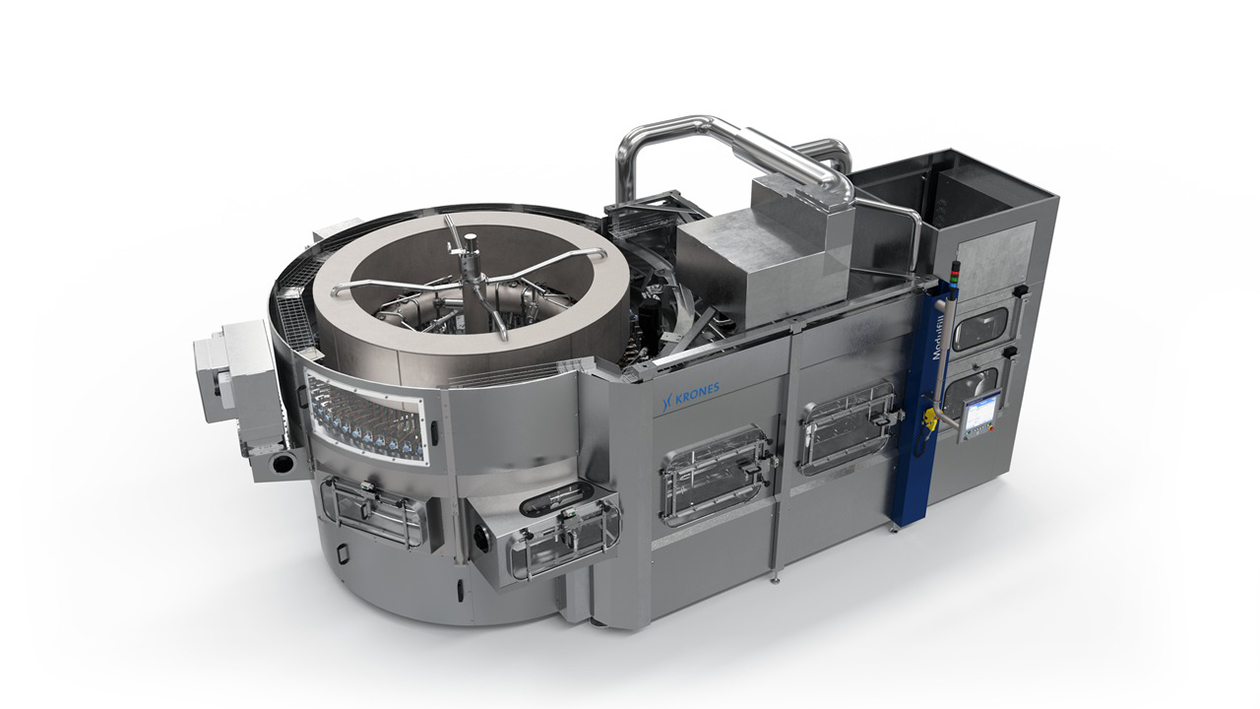

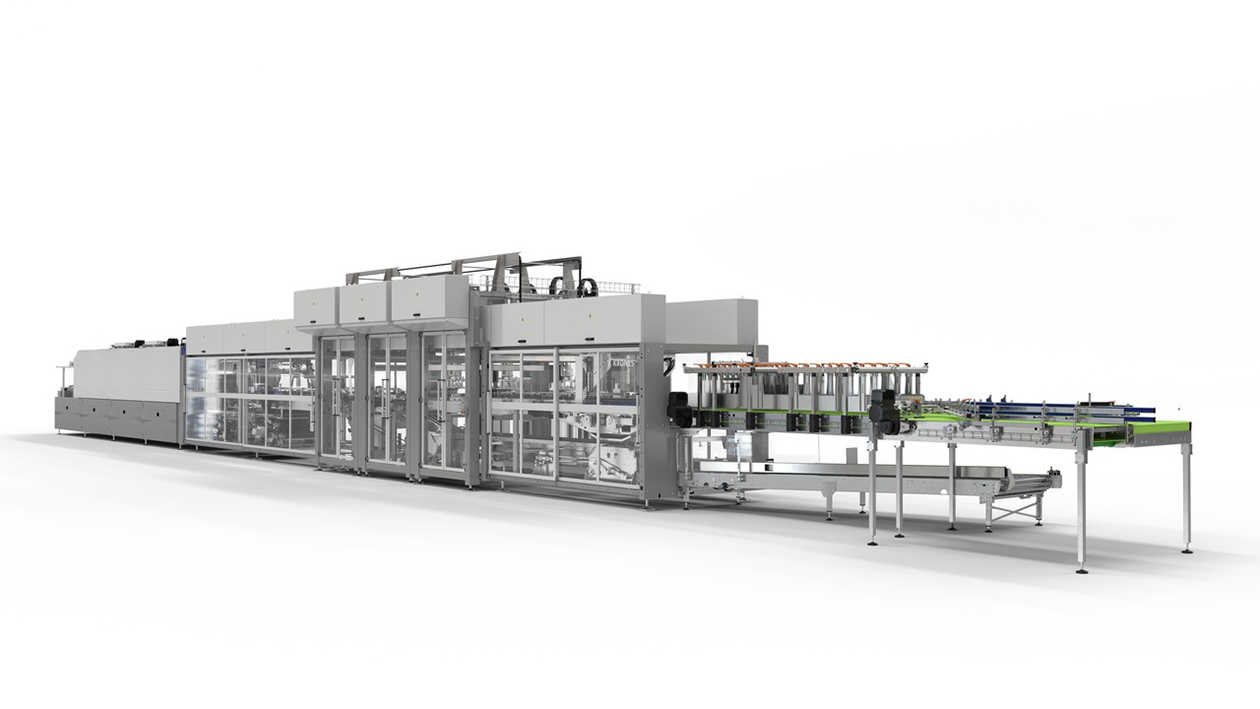

Handiness, recoverability and high product integrity are reasons enough for our customers to devote increasing attention to can filling at present. In Krones, they find an experienced and reliable partner with whom to tackle their next project – who offers a whole range of innovations in this field.