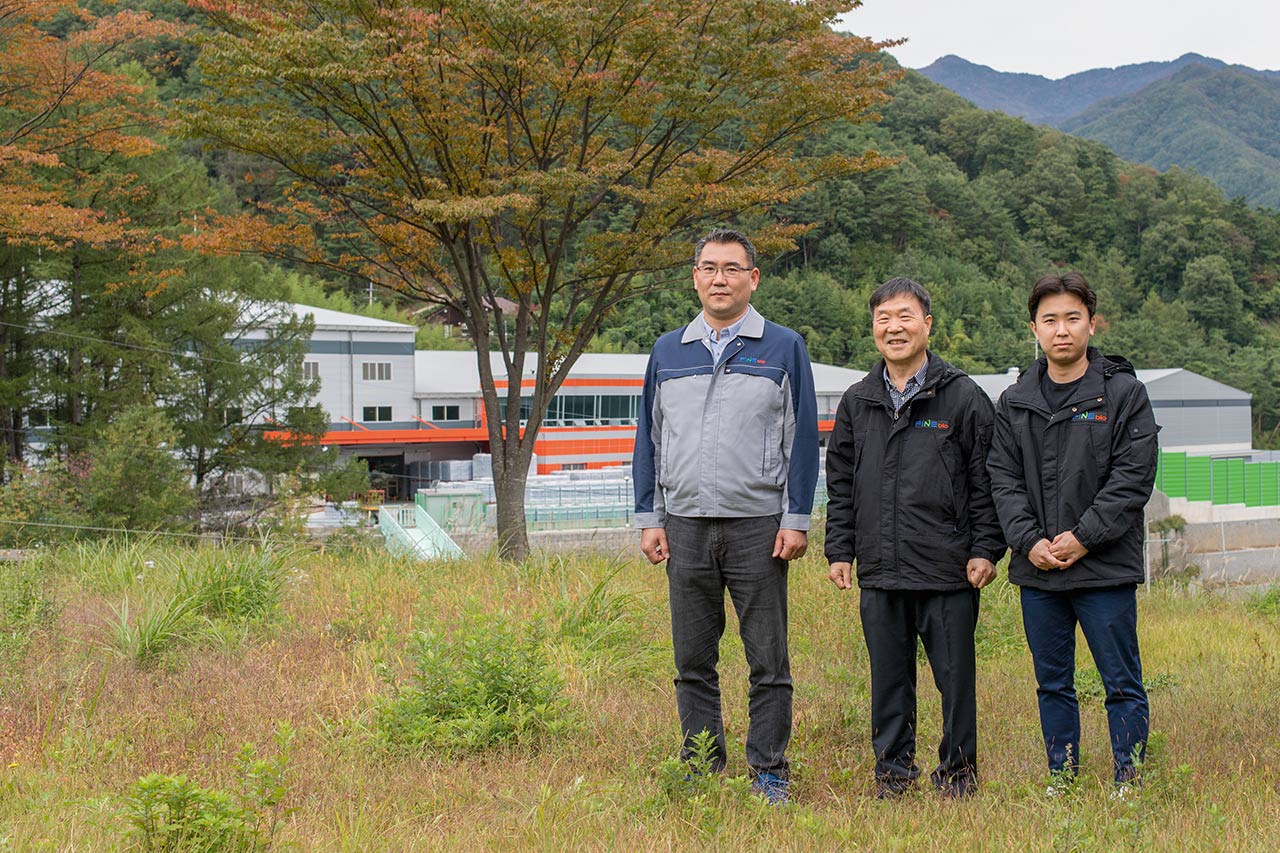

Another special feature is the sheer size of the production operation: “It’s true that with a workforce of about 60 we are a relatively small company, and yet we are the Number One on the Korean mainland in terms of water intake quantity,” relates a proud Jason H.J Yoon, Sales Team Manager at Fine Bio.

So as to put the necessary technical preconditions in place, those responsible at Fine Bio set out to identify a machinery vendor that was able to provide the requisite assistance with his know-how, experience and the right technology – and in the shape of Krones found the partner they had been looking for: “Krones enjoys an excellent reputation among water bottlers, and with its Korean subsidiary has a highly active team on the spot. We went in search of a compactly dimensioned, efficient solution – and this is precisely what the ErgoBloc is,” says Shin Kwang-Yoon.

For production start-up in 2016, Fine Bio invested in two lines, each of them featuring space-saving block technology both in the wet end and in the dry end. Two ErgoBloc L and D systems each work side by side, with one line producing, labelling, filling, packing and palletising only two-litre containers, and the other one 0.5-litre PET bottles. The client’s choice of block-synchronised lines was based on several reasons, as Production Team Leader Sung-ki Kim explains: “Our main criterion is a dependable production process, which is what our customers demand from us. At the same time, we had to make sure that the lines’ layout was compactly dimensioned, since due to our plant’s location on the mountainside space is at a premium. Krones’ ErgoBloc solutions met these two stipulations perfectly.” Together the two lines produce around one million bottles a day.