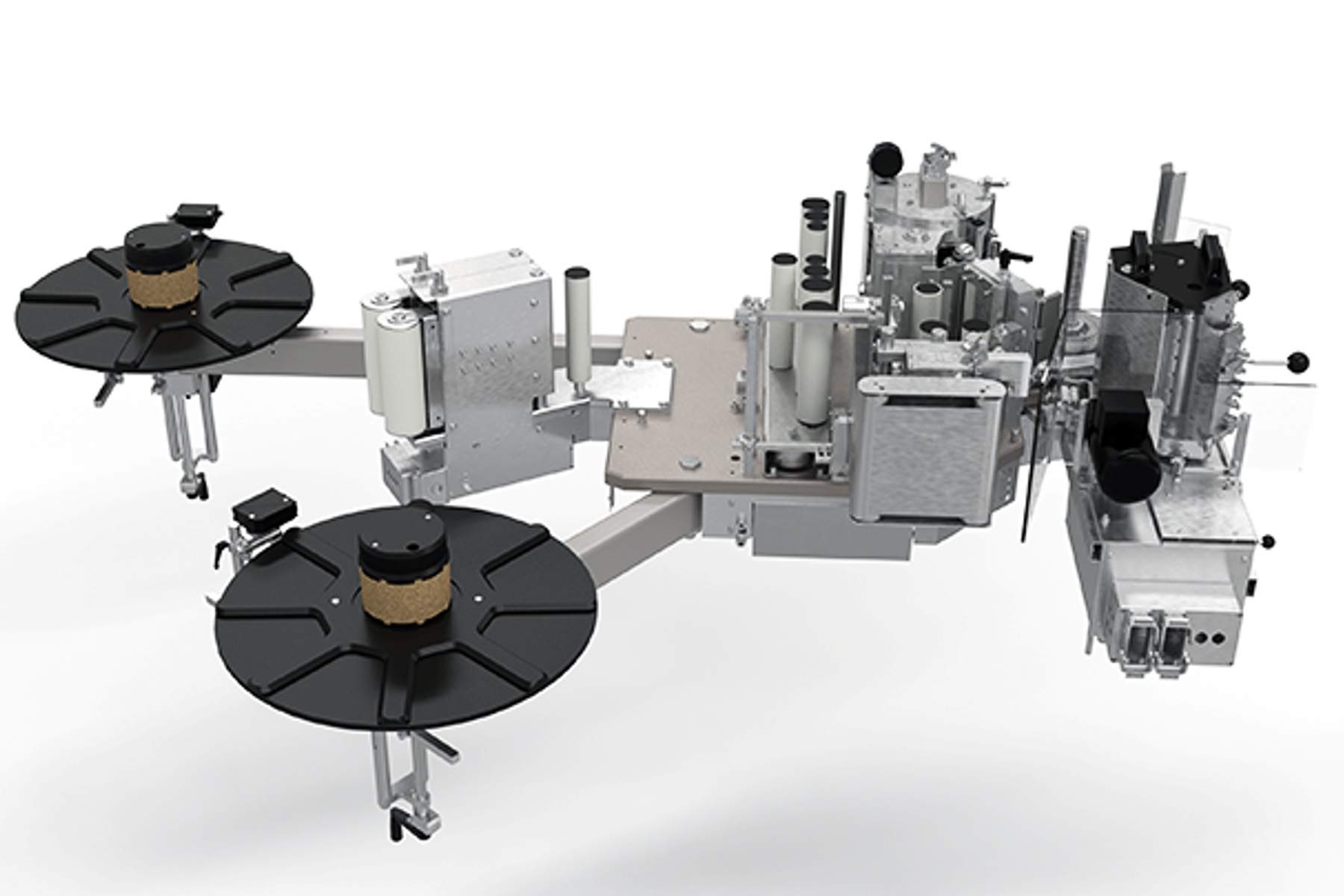

High flexibility with wrap-around labelling

When it comes to decorating containers with wrap-around, reel-fed labels, the Contiroll has been setting the benchmark for many years now. The machine has been designed as a rotary machine and is equipped with a precisely operating labelling station. With regard to efficiency, accuracy and speed, the Contiroll absolutely takes a leading position.

At a glance

- Wrap-around labelling of cylindrical and specially shaped containers

- Precise container fixing using centring bells and container plates

- High-speed access to the user interface through individual transponders

- Remote maintenance is available as an option

Method of operation

In order to tighten the label, the containers are rotated. When the trailing edge is glued down, the secure bond is complete.

A heated glue roller applies a small glue strip to the leading and to the trailing edge of the label.

In the cutting unit, the labels are precisely cut while a computer and servo motor ensure an exact cut-off point.

A feed roller, the speed of which is adjusted to suit the label length, continually pulls the label film from the reel. The label film guider, which is installed as standard, makes sure that the label film is pulled straight.

Variants for wrap-around labelling

- Output range of 3,000 to 72,000 containers per hour, with only one labelling station, depending on the label length

- Variable equipment of the labelling station for processing longer labels as well

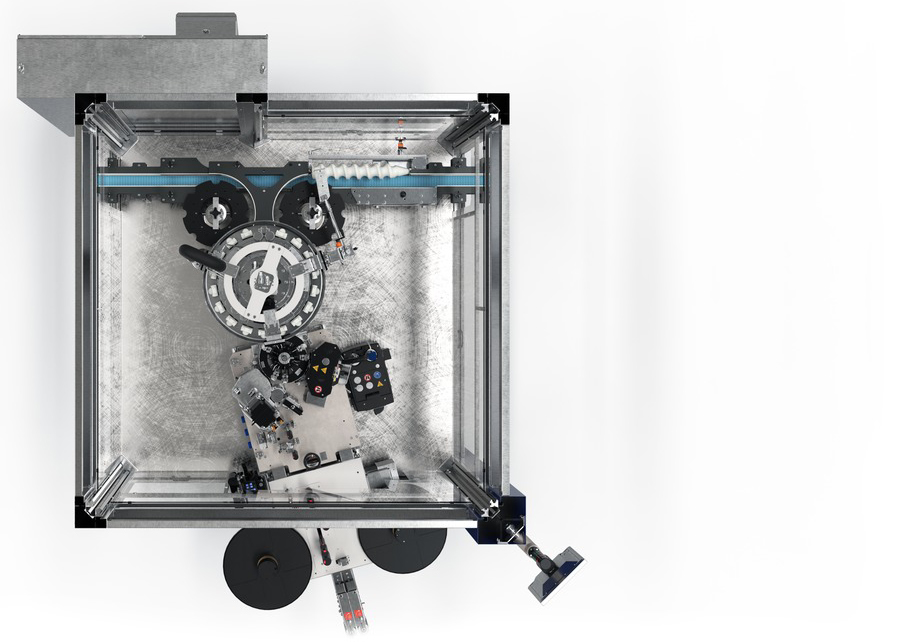

- Integrated servo drive technology for reel holder, feed roller, cutting unit, vacuum-grip cylinder and hotmelt unit

Technical features and benefits

- Hygienic design with smooth surfaces

- Quick and easy cleaning

- Light-weight vacuum-grip cylinders with tool-free locking

- Easy change-over

- Automatic reel splicing unit included as standard

- New gluing unit

- Absolutely controlled glue application thanks to newly developed "Gravure Glue Application" technology

- Insulated glue bowl

- Heat-up phase reduced by up to 20 percent

- Energy consumption reduced by up to 15 percent

- Electronic cutting unit

- Stable and quickly changeable cutter

- Adjustment of the labelling station incline with a handwheel including register

- Manual overlap correction possible during production

- Output range of 3,000 to 36,000 containers per hour, with only one labelling station, depending on the label length

- One common servo drive for the feed roller, cutting unit, vacuum-grip cylinder and hotmelt unit

Technical features and benefits

- Label feed unit with register mark controller

- Vacuum-assisted gripper with mechanical gripper fingers

- Easy change-over

- Automatic reel splicing function available as an option

- Gluing unit with heated glue roller

- Adjustments with handwheel and register

- Optional automatic reel splicing unit

- Optional incline adjustment system with handwheel

Benefits to you

User friendliness

The Contiroll features ease of access and ease of operation.

Low glue consumption

Only two narrow strips of hotmelt are required for container decoration, one at the leading edge and the other one at the trailing edge of the label.

Large output range

The machine covers the full range – from the low output range to the highest.

High labelling precision

Fixation of containers between the centring bell and the container plate ensures a highly precise container decoration.

Time savings

Only short change-over times needed when changing container or label type.

Reduced workload for operators

The Multireel C reel-storage magazine which is available as an option enables the Contiroll to work entirely autonomously for up to eight hours.

Future-proof

The Contiroll can be retrofitted and converted also after many years of operation.

This is why the Contiroll with the TS labelling station is enviro-classified

Energy savings

- Up to 25 percent less energy consumption of the Contiroll TS labelling station thanks to the split vacuum system

- Insulation of gluing unit and glue bowl for an increased operational safety and reduction of energy consumption

Media savings

- Controlled and thus economic glue application thanks to the newly developed "Gravure glue application"

- Reduced number of lubrication points