Smart and reliable empty container inspection

Safe inspection with each revolution

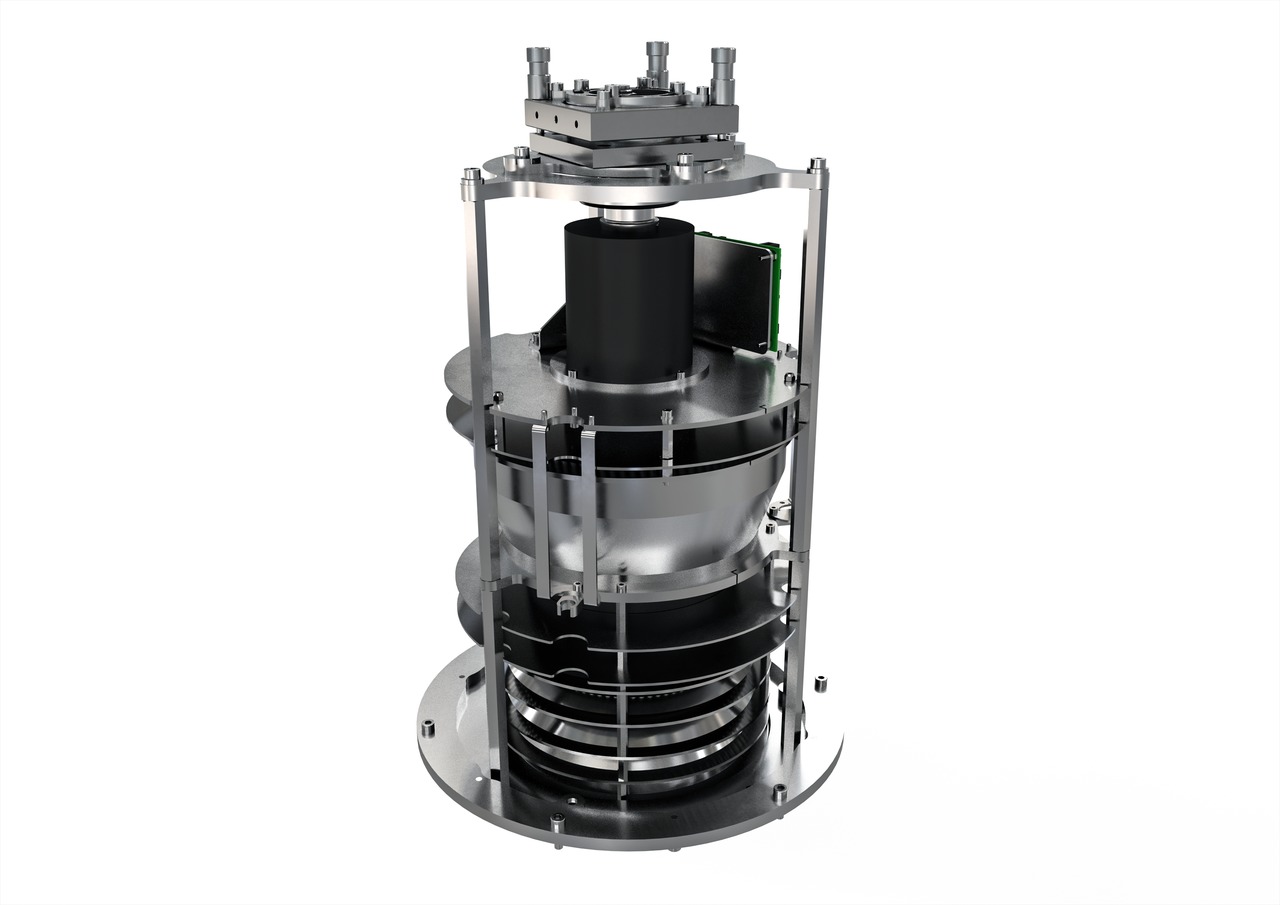

Thanks to its state-of-the-art camera technology, the rotary machine Toptronic inspects empty containers very precisely and reliably. Sophisticated inspection modules can detect even the smallest damage and dirt on returnable glass and PET bottles. Which of the many inspection units you want to use is entirely up to you.

At a glance

- Inspection of empty returnable glass containers

- Modules for all-surface bottle inspection

- Foreign container detection

- Side-wall inspection including film and scuffing detection

- Sealing surface inspection

- Base inspection including film detection

- High-frequency residual caustic detection

- Infrared residual liquid detection

- Inner side-wall inspection

- Lateral neck finish inspection and rust detection

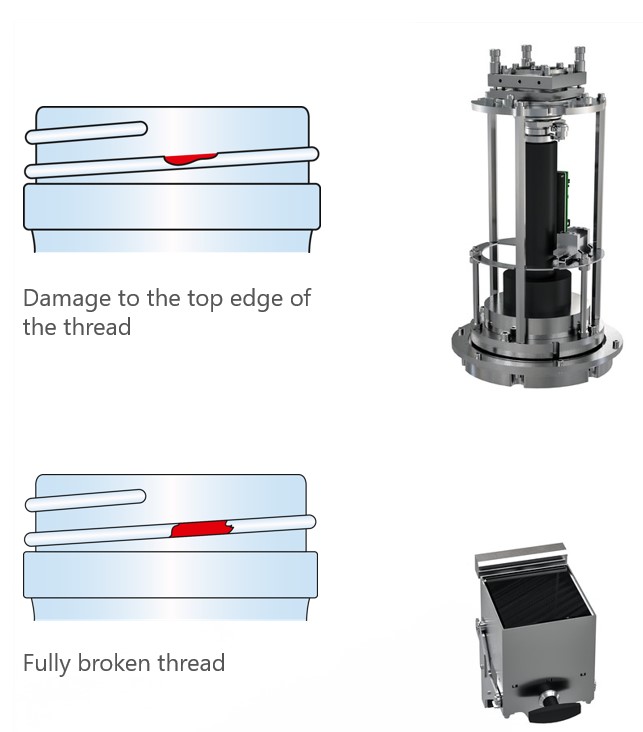

- Thread inspection

Modules for all-surface bottle inspection

Foreign container detection

| Technology used | Two sensors | Camera |

| Inspects the containers for | Height (too high/too low) |

|

| Benefits to you |

|

|

Side-wall inspection

Technology used

- Two cameras

- Permanent container rotation

- A total of eight views per container

- Result: 360° side-wall inspection

Inspects the containers for

- Non-transparent contamination

- Semi-transparent contamination

- Scuffing: Scuffing creates its own rejection signal independent of the side-wall analysis

Residual liquid and residual caustic detection

Technology used

| infrared | high-frequency | |

| Inspects the containers for |

Water and other residual liquids at a level of 3 mm above the centre of the base |

|

| Benefits to you | Very high product safety |

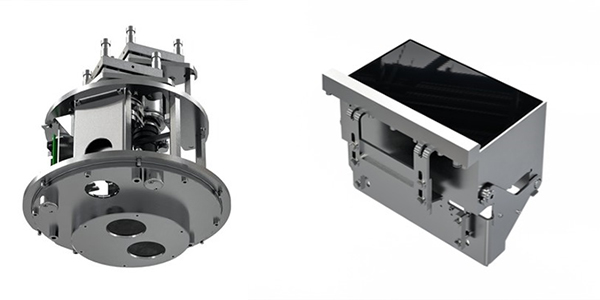

Inner side-wall inspection

Technology used

Camera

Inspects the containers for

Protruding semi-transparent and non-transparent dirt particles from a size of 1 mm (depending on the shape and quality of the container)

Lateral neck finish inspection and rust detection

Technology used

Colour camera

Inspects the containers for

- Rust deposits

- Chips below the neck finish

- Mortar splashes

Benefits to you

Safety for you and your products

The Toptronic protects your consumers against unpleasant surprises. For its inspection modules scrutinise every container and detect event the smallest defects or irregularities.

Economic operation

Inspection modules capable of multitasking, energy-saving components and a false rejection rate of just 0.3 percent prove that it is also possible to create maximum production reliability with a low total cost of ownership.

Easy expandability

Would you like to expand the inspection performance of your Toptronic? No problem - since additional inspection modules can be easily and quickly retrofitted.

Seamless tracking

In order to prevent the containers from shifting, they are conveyed through the machine in a fixed position. Therefore, nothing can stop them from being seamlessly tracked.