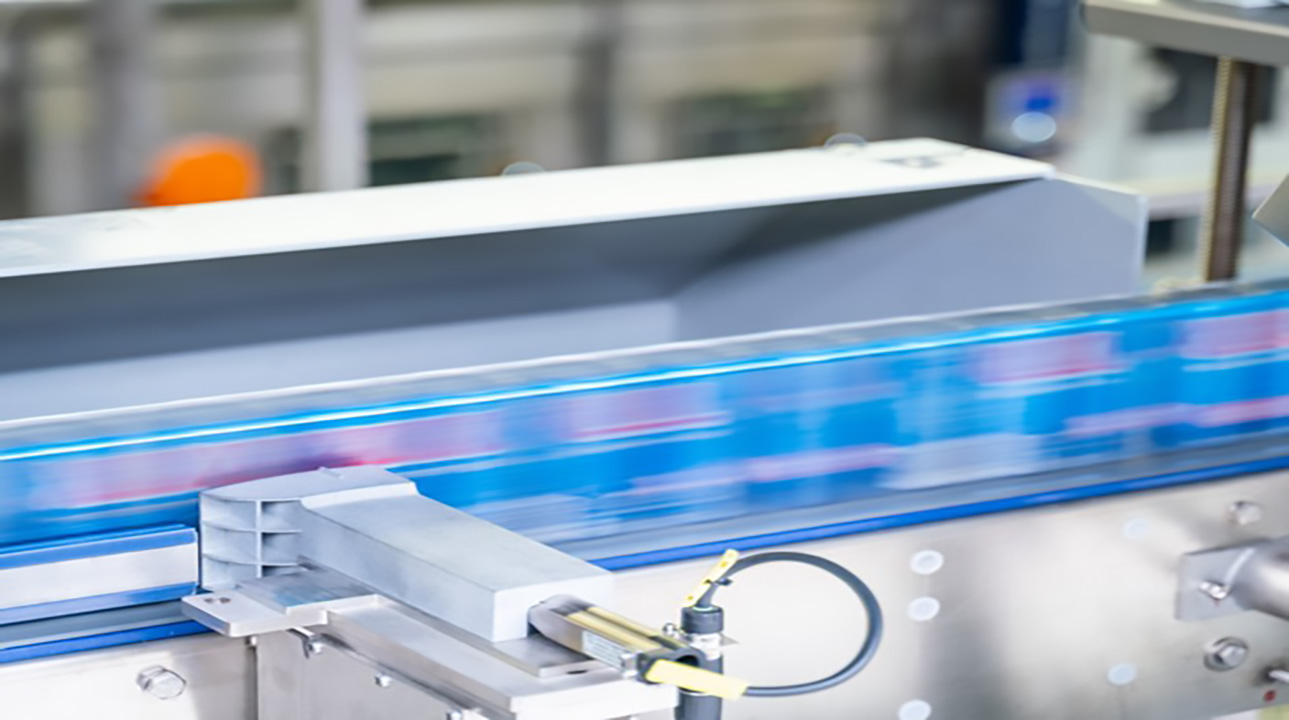

Systems for rejecting bottles after quality control

The right choice for every application

The electrical rejection system from Krones reliably and smoothly rejects from the production flow any containers that have been rejected. You can choose from a number of different systems depending on the application and line layout.

At a glance

- Ecopush:

- Empty and full glass containers

- Empty and full cans

- Full PET containers

- Ecoslider:

- Full or half-full glass containers

- Full or half-full cans

- Full or half-full PET containers (standing rejection, depending on the container)

- Ecoslider Pro:

- Empty or full glass containers

- Full cans

- Full PET containers (standing rejection, depending on the container)

- Varioglide:

- Empty and full glass containers

- Empty and full non-returnable and returnable PET containers

- Ecoselect:

- Full or half-full glass containers

- Full or half-full cans

- Full or half-full PET containers

- Ecoselect Pro:

- Full or half-full glass containers

- Full or half-full cans

- Full or half-full PET containers

Rejection systems at a glance

Ecopush: For cans and glass / PET containers

Field of applications

- Empty glass containers

- Empty and full cans

- Filler: Full glass containers

- Labeller: Full glass and PET containers

- Output of up to 130,000 containers per hour

Technical features

- Electrical rejection unit

- The bottles are rejected onto a rejection table, into a collecting bin or on parallel conveyors.

- Bottle sorting possible

- Linear motor with movable, magnetic slider

- Option: Ecopush Dual with two pushing speeds

Benefits to you

- Energy-saving operation without compressed-air consumption

- Low noise level

- No maintenance work needed

- Space-saving double function: Rejecting and sorting

- Rejection chute free of glass fragments

Ecopush: Rejection system for cans

Field of applications

- Cans

- Output of up to 130,000 cans per hour or 3.0 metres per second

Technical features

- Electrical rejection unit

- Horizontal pusher movement

- Cans are rejected into a collecting bin – lying on their sides also possible

Benefits to you

- Energy-saving operation without compressed-air consumption

- High performance

- Cost-efficient system

Ecoslider: For full and half-full containers

Field of applications

- Cans

- Glass containers

- PET container

- Full or half-full

- Output of up to 72,000 cans per hour or 2.0 metres per second

Technical features

- Electrical rejection unit

- Rejection of the bottles onto a rejection table or into a collecting bin

- Container sorting possible

- Compact design

Benefits to you

- Energy-saving operation without compressed-air consumption

- Low noise level

- No maintenance work needed

- Low space requirements

Ecoslider Pro: For full and half-full containers

Field of applications

- Empty and full glass containers

- Full and half-full PET containers (standing rejection, depending on the container)

- Full cans

- Output of up to 72,000 cans per hour or 2.0 metres per second

Technical features

- Electrical rejection unit

- Rejection of the bottles onto a rejection table or into a collecting bin

- Container distribution possible

- Compact design

Benefits to you

- Energy-saving operation without compressed-air consumption

- Low noise level

- No maintenance work needed

- Low space requirements

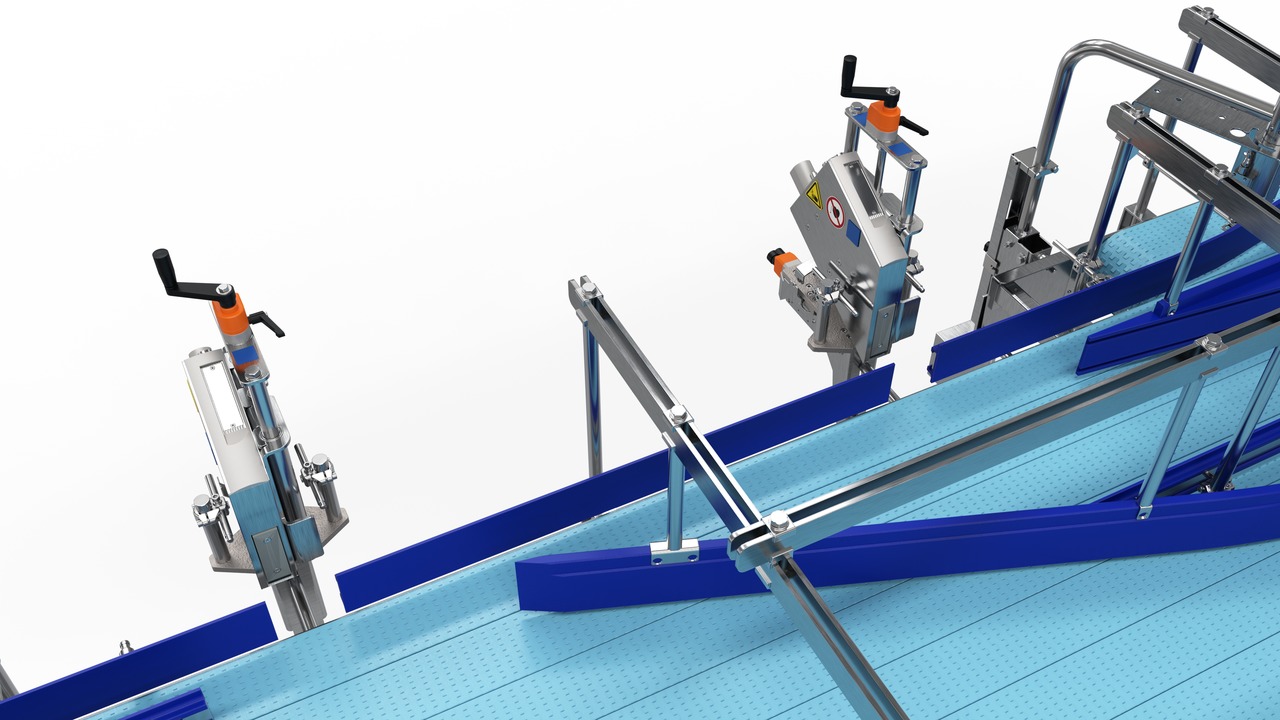

Varioglide: Linear rejection system with variable rejection elements

Field of applications

- Glass containers

- Non-returnable and returnable PET containers

- Output of up to 70,000 cans per hour or 1.8 metres per second

Technical features

- Electrical rejection unit

- Containers are rejected onto a rejection table or parallel conveyors

- Container sorting possible

Benefits to you

- Energy-saving operation without compressed-air consumption

- Modular design, therefore individually customised

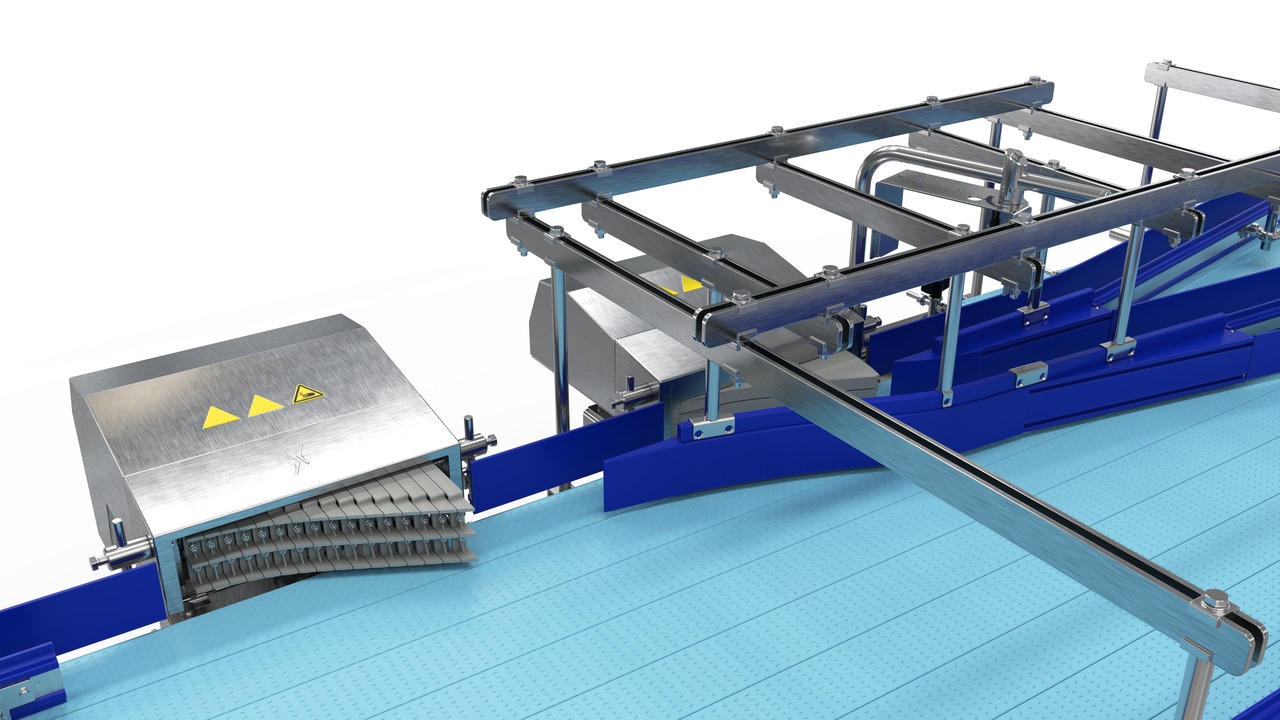

Ecoselect: For cans and glass / PET containers

Field of applications

- Quality-check rejection

- Cans

- Glass containers

- PET container

- Full or half-full

- Output of up to 132,000 cans per hour or 2.2 metres per second

Technical features

- Electrical rejection unit

- Rejection of the bottles onto a rejection table or conveyor

- Container distribution possible

- Compact design

Limitations

approx. 400 mm gap in the container flow necessary

Ecoselect Pro: For cans and glass / PET containers

Field of applications

- Quality-check rejection

- Cans

- Glass containers

- PET container

- Full or half-full

- Output of up to 132,000 cans per hour or 2.2 metres per second

Technical features

- Electrical rejection unit

- Rejection of the bottles onto a rejection table or conveyor

- Container distribution possible

- Extended design for safe rejection for demanding container shapes

Limitations

approx. 120 mm gap in the container flow necessary

How can we help you?

Additional information

Download

Do you have any questions?

Contact

Krones nearby you

Sales network

Come and visit us

Events