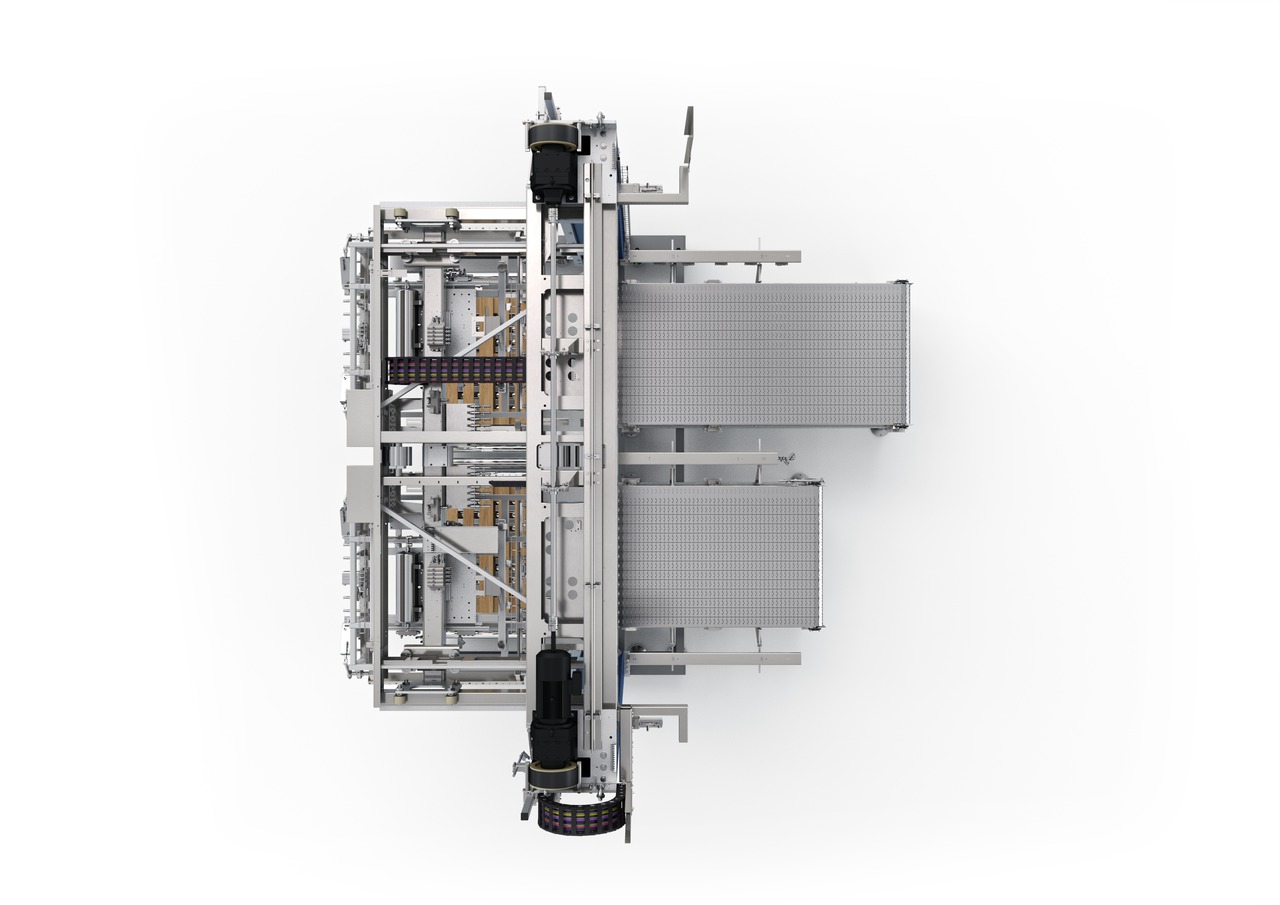

Palletising and depalletising of plastic crates

Depalletising pallets containing crates with empties requires speed, but also the grouping of layers and the palletising of full-container crates should be done reliably and with high output. The Pressant Duplex 2NT solves both tasks with expertise. In addition to the individual design for the respective product and line configuration, it is primarily characterised by their ability to master a gentle gripping process specifically for plastic crates.

At a glance

- Palletising and depalletising of plastic crates

- Output: Up to 840 layers per hour – depending on the design

- Gentle handling of plastic crates with jaw gripper head or hook gripper head

Method of operation

The Pressant Duplex 2NT palletiser is mainly designed for the high output range thanks to its use of two palletising or depalletising stations. This machine is also equipped with two lifting columns and stands out for its high load capacity.

- In the Pressant Duplex 2NT palletiser, the packs are firstly pre-grouped in layers in two grouping stations.

- The gripper heads lift up the layers.

- Then, a telescopic transverse travel station moves the layers to the prepared pallet and sets them down.

- Designed as a depalletiser, the Pressant Duplex 2NT simultaneously lifts one layer from the each of the two pallets and sets it down on the pack discharge tables.

2NT = 2 pallet positions, level balancing, telescope

Pack handling

Lifting unit

In the Pressantseries, two lifting columns with a telescopic transfer carriage are used.

Pack discharge table or grouping system

Depending on the application in either single-lane or double-lane concept, the pack supply or removal can be designed in rectangular or linear design.

Gripper head

Gripper systems for picking up the packs from the grouping station or from all four sides for gentle transportation.

Benefits to you

High performance

The duplex design makes it possible to palletise or depalletise two pallets in one cycle.

High positioning accuracy

Precise gripping technology and finely tuned lifting unit transfer motions ensure precise movement sequences during palletising and depalletising – and therefore high speeds for returnable packs.

Economic continuous operation

Durable assemblies and components guarantee the highest reliability and high system accessibility – even in continuous operation mode.

Ease of operation

The well-arranged structure of all functions on the touch-screen allows for quick handling of all operating tasks.

Variable line layout

The grouping station and the discharge table can be arranged at a 90 degree angle. This way, the palletising system is perfectly suited to all line layouts.