All-rounder for packing and unpacking

High output and flexibility are key qualifications

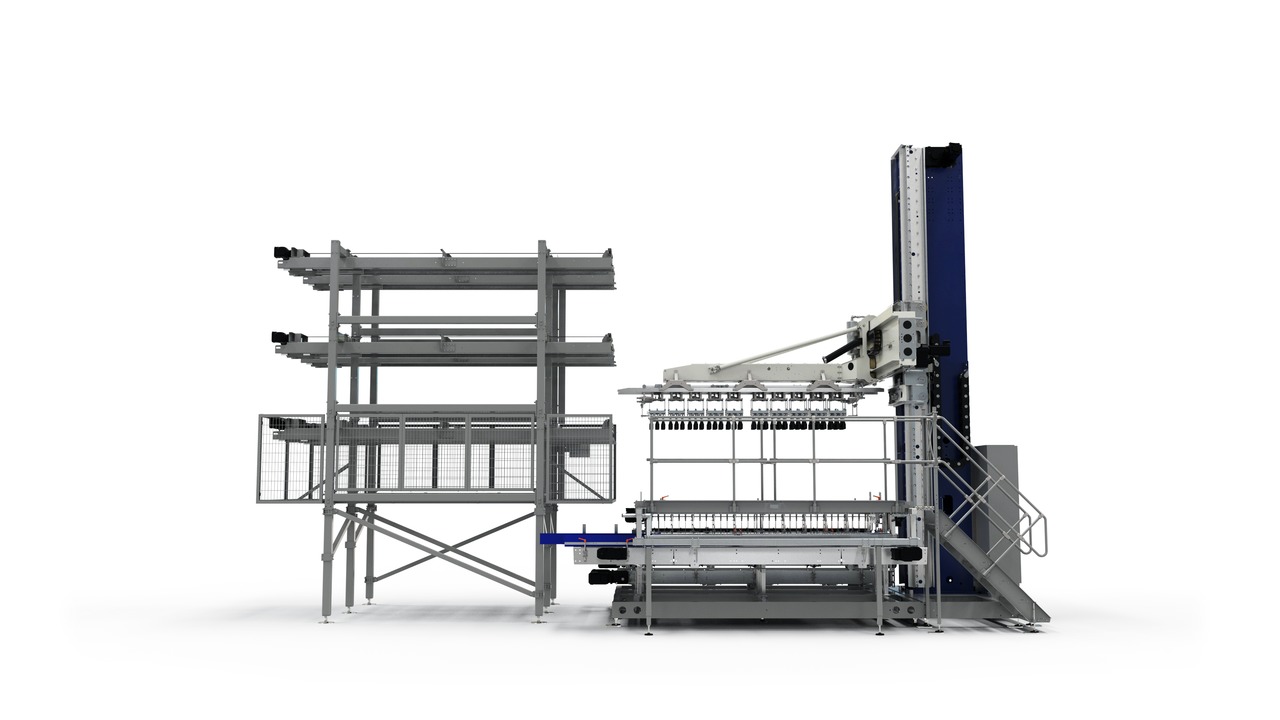

The packing and unpacking process in a beverage plant must run like clockwork. Fast and gentle container handling and high flexibility to suit a wide variety of containers are the basic pre-requisites. On top of that, a packing and unpacking machine should be easily integrated into operational sequences and smoothly fit into the line layout. The Linapac II fully meets these requirements. Last but not least: sorting systems, as well, benefit from its high-performance technology.

At a glance

- Intermittent packer for

- cylindrical and specially shaped containers made of glass or plastic

- multi packs

- Processing of pack block lengths ranging from 1,600 to 3,300 millimetres

- For packing and unpacking of packs which are open at top side

- Integration in empties sorting systems

Method of operation

Packers operating in cycles for flexible mastering of packing and unpacking tasks

Packing

- The bottles on the container table are grouped onto lanes

- The pre-positioned containers are picked up using gripper units and set into the fed empty packs

Unpacking

- The filled packs are fed to the unloading position on the conveyor

- Gripper unit lowering and container pick-up from the pack, and container positioning on the container table

Packing curve

- Freely programmable packing curve with independent control of the drives of lifting column and horizontal axis

- Various positions can be approached within the operating range

- Precision control system to ensure accuracy of movement to the nearest millimetre as well as gentle start-up and braking

Technical features

Various sizes allow an optimum integration of the Linapac II in many different line layouts. The models vary regarding the container table

width and pack conveyor length, which makes the Linapac II a perfect partner for individual packing processes

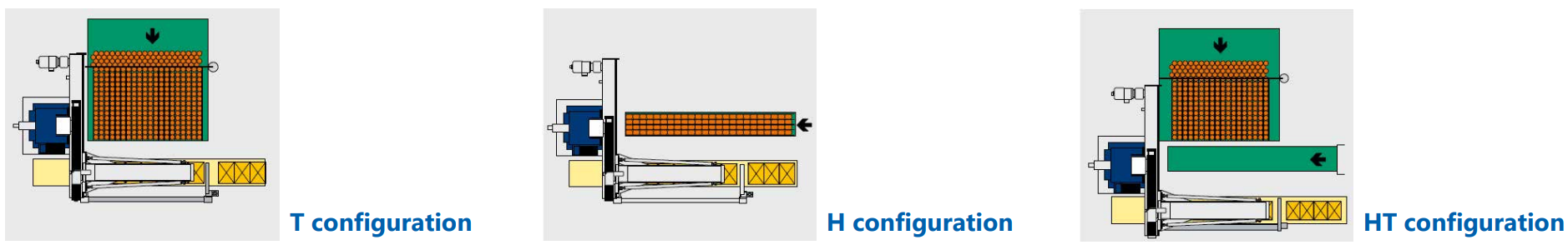

Layout configuration

- T design for cylindrical containers

- H design for cylindrical containers and multipacks

- HT design for cylindrical containers or multipacks as an option

Benefits to you

Flexible application

The multifunctional Linapac II can pack and unpack the containers. It can also handle combined packing and unpacking as well as sorting tasks with ease.

High operational reliability

The robust design of all assemblies and elements ensures a smooth and reliable packer operation.

Low space requirements

Thanks to its small dimensions, the Linapac II can also be easily installed on small surfaces.

Great processing range

The wide range of gripper unit variants allows the safe and gentle handling of a large number of different container types.

Quick change-over

The high degree of automation results in the type change-over requiring only a few simple steps. As an option, the packer can be equipped for fully automatic handling parts change-over.