Hot filling of juice and standard filling of carbonated beverage in PET

The most important features

- Infinitely variable control of the filling speed by the Krones Proportional Flow Regulator (PFR)

- Precise determination of fill quantity via inductive flow meter

- Recirculation channel for heat retention of the product

- Cleaning in a closed system using automatically positioned CIP cups

- Version in hygienic design

- Product feed from top via adjacent product tank

- Bottling of carbonated products possible without any conversion

Output

- Up to 78,000 containers per hour

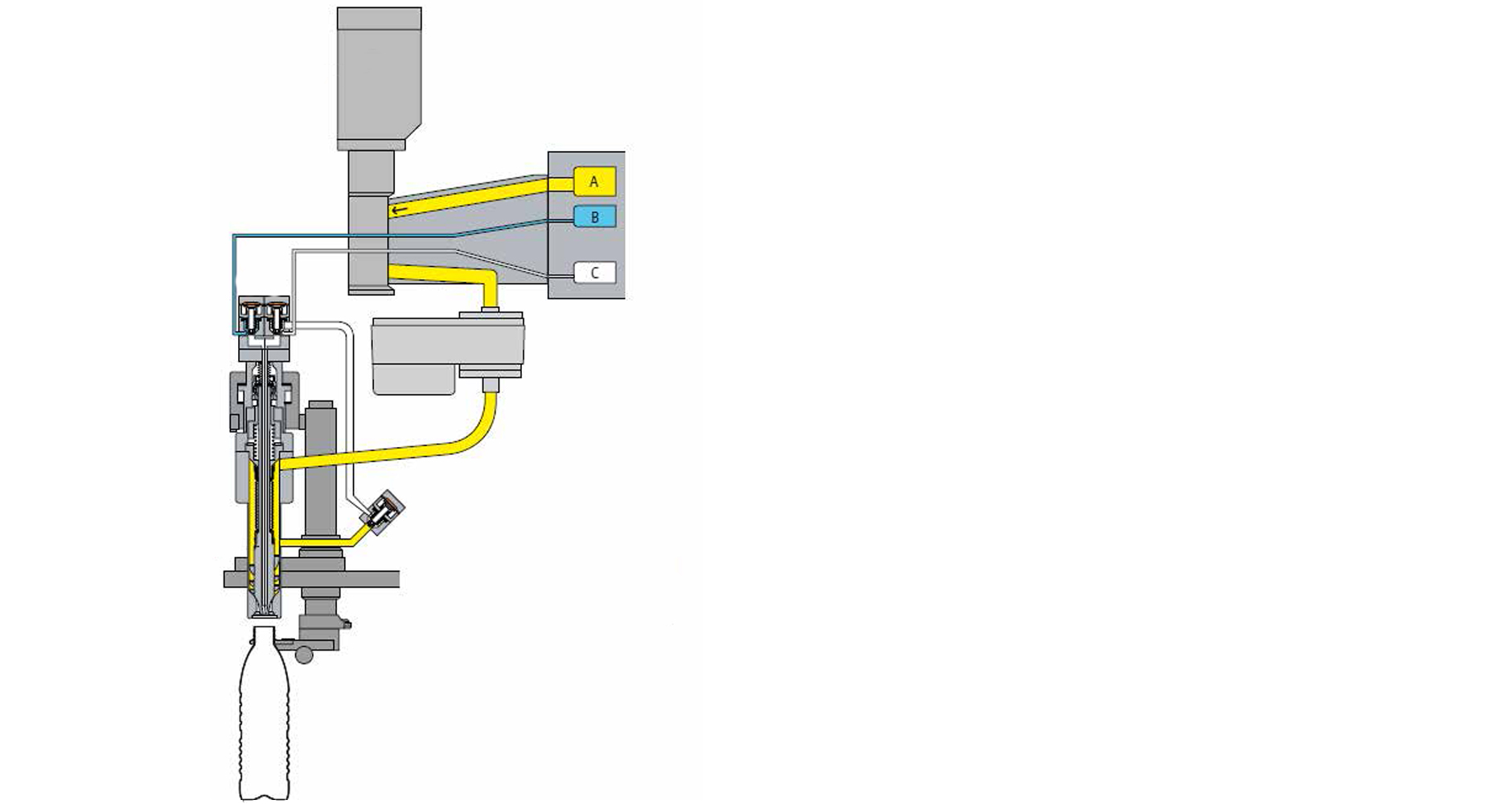

VFS = Volumetric filling system, Flow meter, Short tube

Filling vales

Snifting and hot-return channel (CIP return channel)

Pressurisation and return gas channel

Product channel

Hot product return valve (CIP return valve)

PFR control valve

Snifting valve (CIP return valve)

Pressurisation and return gas valve

Product stem

Benefits to you

Energy-efficient method of operation

Servo drives with individually adjusted motor sizes

Hygienic design

- Little surfaces to clean

- Stainless steel design

- Easy accessibility for cleaning

Modular design

- Can be expanded later with a rinser or several cappers

- If required: Block synchronisation with other machines possible

How can we help you?

Additional information

Download

Do you have any questions?

Contact

Krones nearby you

Sales network

Come and visit us

Events