Full jet filler for filling non-carbonated water in PET

Fresh technology for a refreshing thirst-quencher

Full jet filling

- Electronic filling system with inductive flow meter or mass flow meter

- Full jet filling for utmost microbiological safety

- Infinitely variable control of the filling speed by the Krones Proportional Flow Regulator (PFR)

- End of filling after signal from flow meter

Field of applications

- Filling of non-carbonated water into PET containers, both with and without conductivity

Output

- Up to 100,000 bottles per hour

VFJ = Volumetric filling system, Flow meter, Full jet

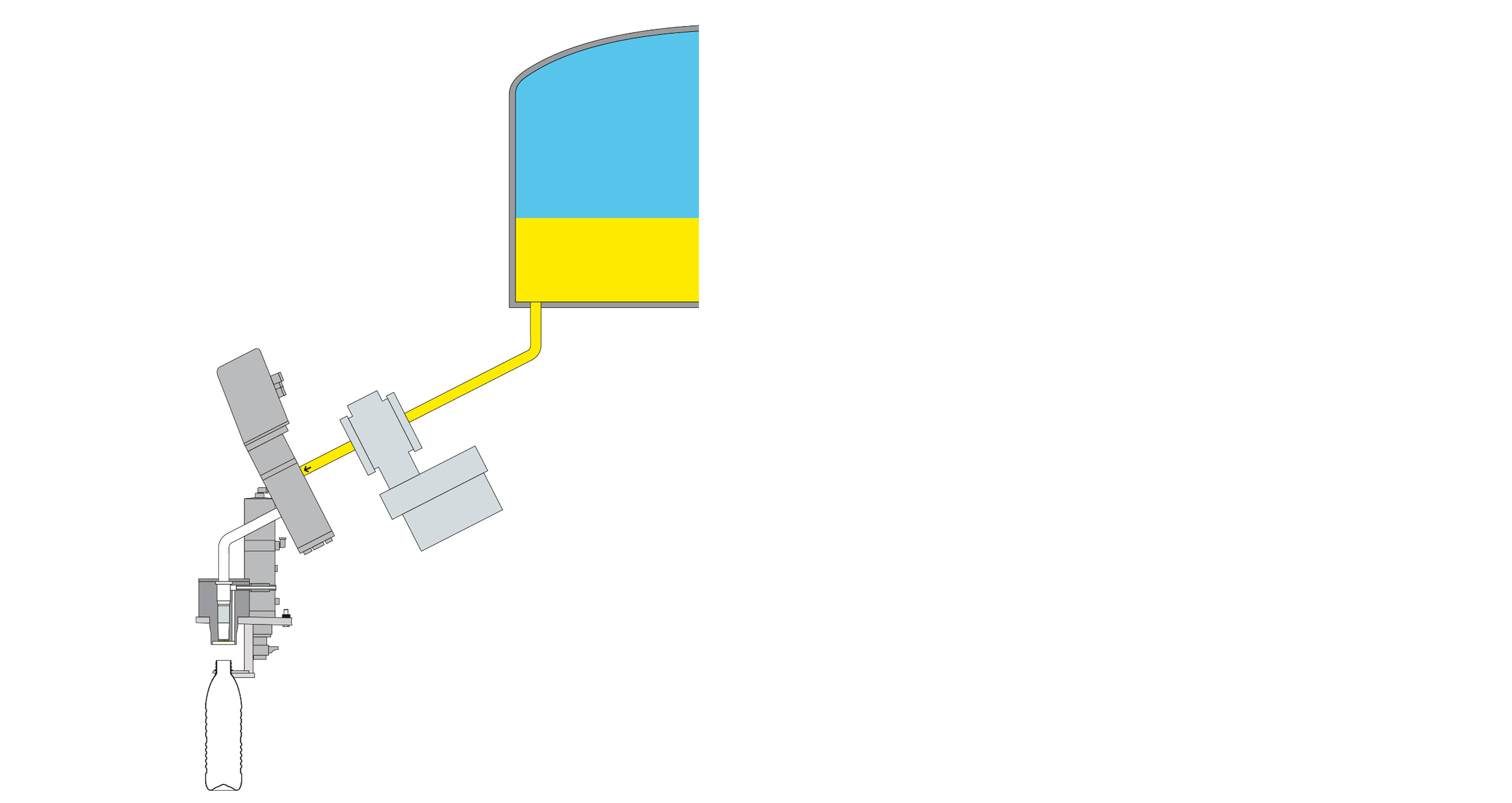

Functional principle of the valve

Neck-handling grippers position the PET container beneath the filling valve. Once the container has been centred, the filling process starts: Thereby, the PFR valve (Proportional Flow Regulator) is opened and the product flows into the bottle at an infinitely variable speed. Once the required fill volume has been reached, the flow meter provides a signal to the PFR valve. The valve is now closed and the filling process completed. Dripping of the filling valve is prevented by a sieve in the product discharge.

Optional

- Automatic CIP cups

Conductivity > 20 µS/cm

Viskosity < 10 mPa·s

Inductive flow meter

PFR valve

CIP channel and vent tube

Product tank

Benefits to you

Microbiological safety

- Contact-free filling and optimised machine design

High filling accuracy

- Use of flow meters and infinitely variable flow speeds

High availability

- Top efficiency thanks to the combination with Krones cap feed systems

Ease of maintenance

- Simple maintenance and assembly of the PFR valve

Reduced standstill times

- High degree of automation by using automatically positioned CIP cups

Low consumption of media

- When using PFR valves: significant reduction of the energy demand of the machine by about 90 percent

How can we help you?

Additional information

Download

Do you have any questions?

Contact

Krones nearby you

Sales network

Come and visit us

Events